Electrorheological fluid and preparation method thereof

An electrorheological and liquid technology, used in lubricating compositions, additives, petroleum industry, etc., can solve the problems of high yield strength, poor service life, low yield strength, etc., and achieve high yield strength, small leakage current and long life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

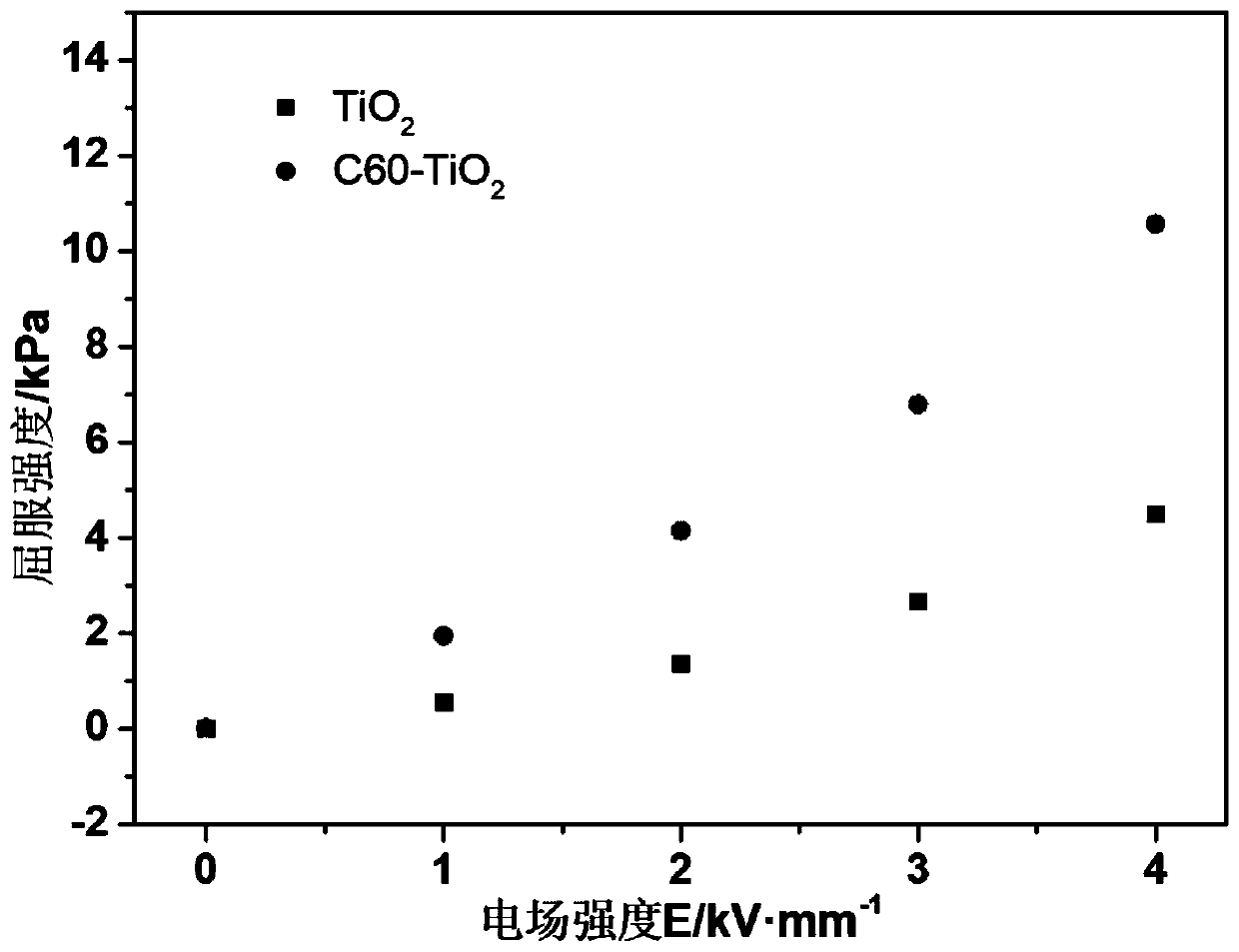

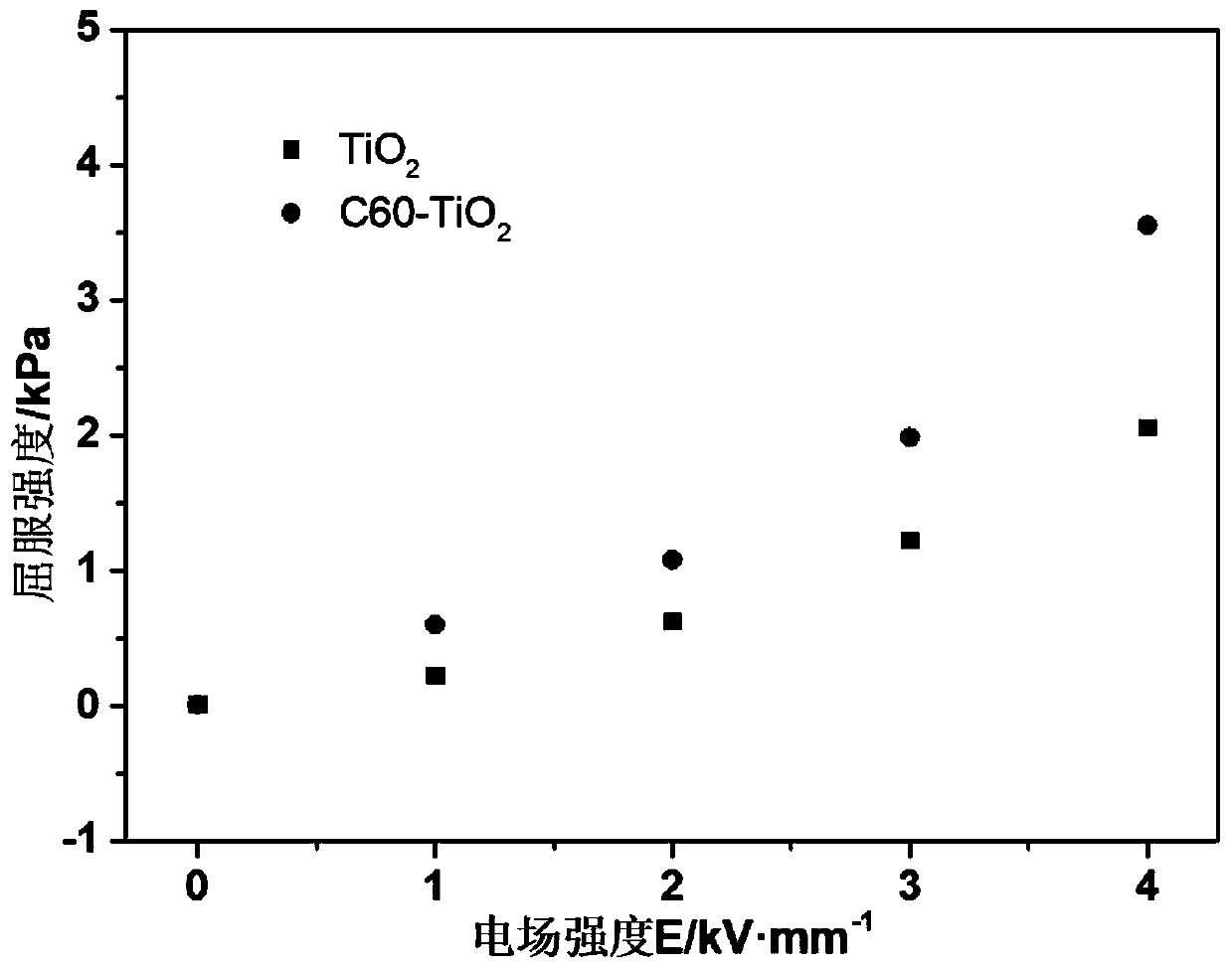

[0028] 1 part of C60 particles (density 1.68g / cm 3 ) and 200 parts of simethicone oil (viscosity 20cst, density 0.97g / cm 3 ) mixed, and ultrasonically dispersed for 30min to obtain a C60-silicone oil suspension; 50 parts of titanium dioxide particles (with a density of 4.2g / cm 3 , with a particle size of 1.5 μm) was added to the C60-silicon oil suspension, ground carefully, and finally heat-treated at 150° C. for 2 hours to remove water to obtain an electrorheological fluid.

Embodiment 2

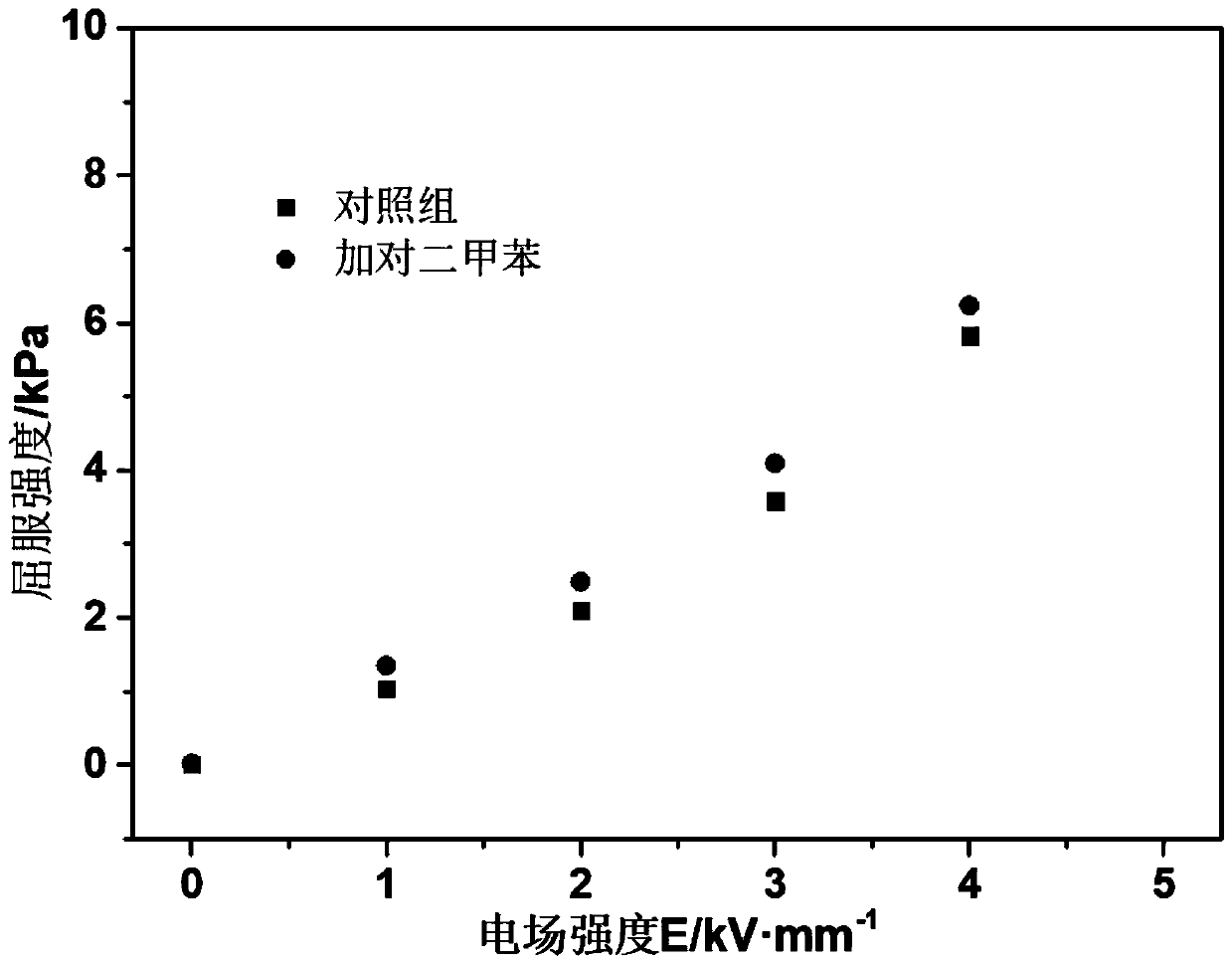

[0030] First, 1 part of C60 (density 1.68g / cm 3 ) and 100 parts of xylene (analytically pure, density 0.86g / cm 3 ) mixed and stirred for two hours to obtain a uniform C60-xylene solution; 100 parts of titanium dioxide particles (density of 4.2g / cm 3 , with a particle size of 1.5 μm) was added to the above C60-xylene solution, heated to 140°C after stirring for half an hour, and continued to stir until evaporated to dryness to obtain C60-titanium dioxide particles, that is, C60 was adsorbed on the surface of titanium dioxide. Mix C60-titanium dioxide particles with 100 parts of silicone oil (500cst, density 0.97g / cm 3 ) mixed, carefully ground, and finally heat-treated at 150°C for 2 hours to remove moisture to obtain an electrorheological fluid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com