Supercharging system for engine and control method

A supercharging system and control method technology, applied in the direction of engine control, combustion engine, machine/engine, etc., can solve the problems of limited supercharging pressure, turbo hysteresis, poor transient response, etc., to increase engine power, reduce fuel consumption, The effect of prolonging the life cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention is described in detail below in conjunction with accompanying drawing:

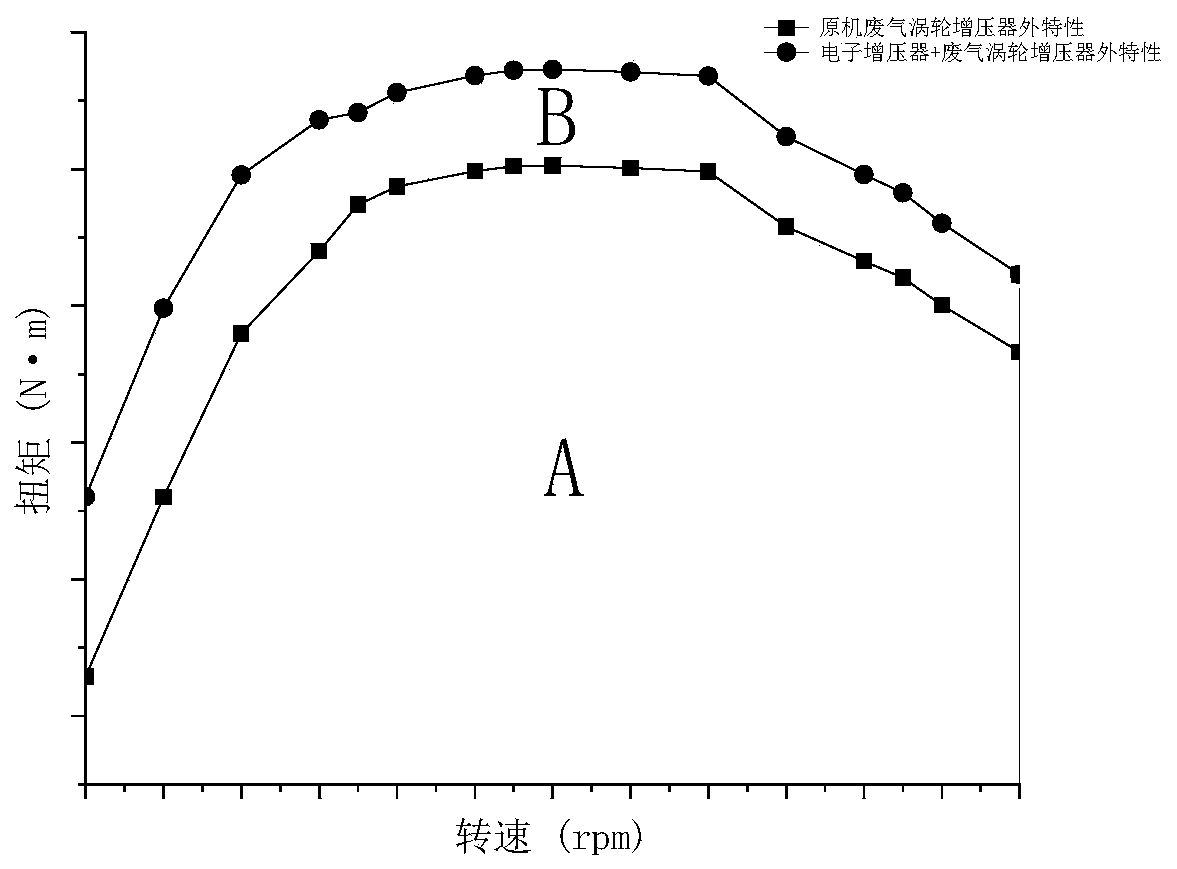

[0036] refer to Figure 5 , is an example given for the supercharging scheme.

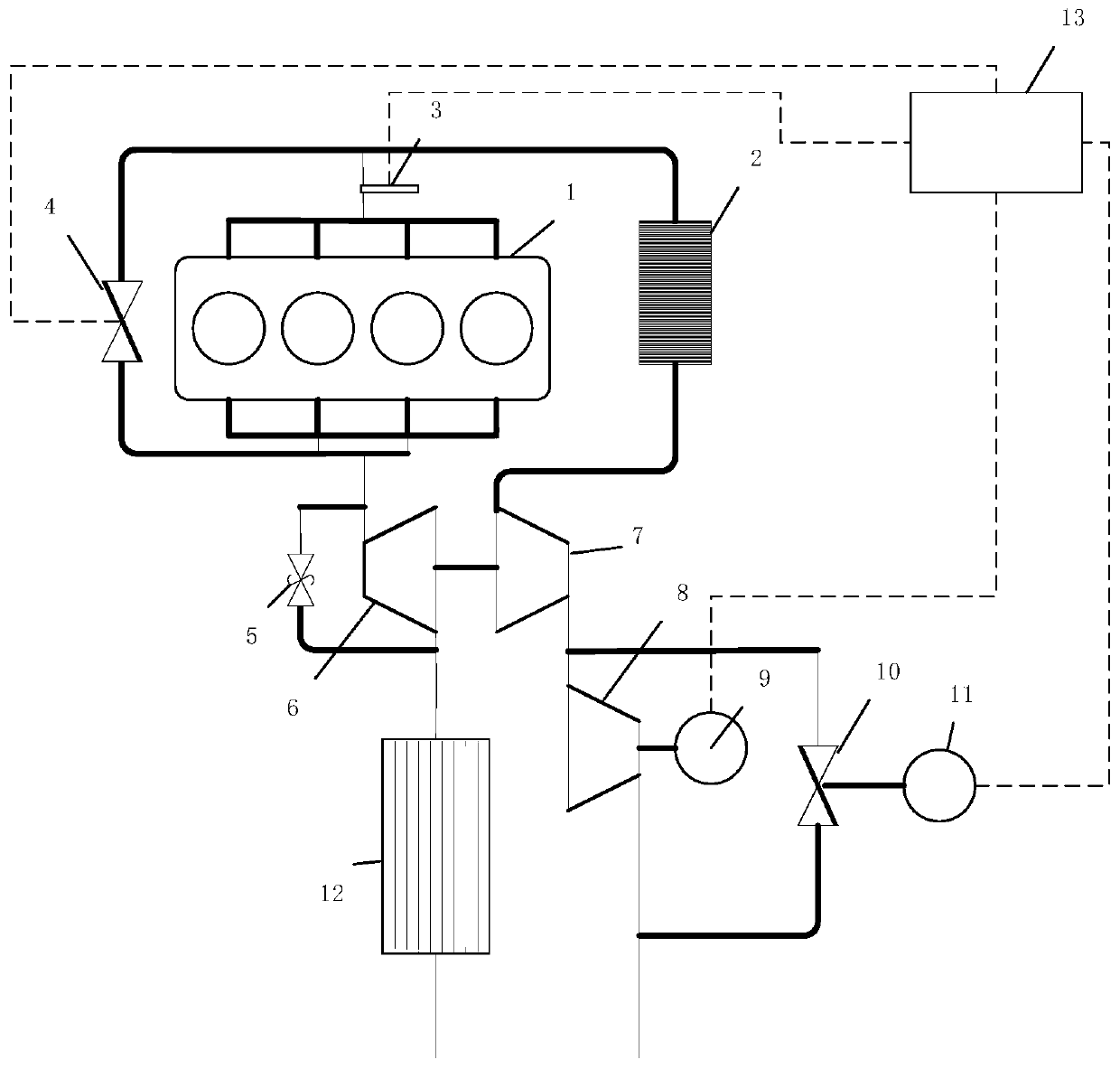

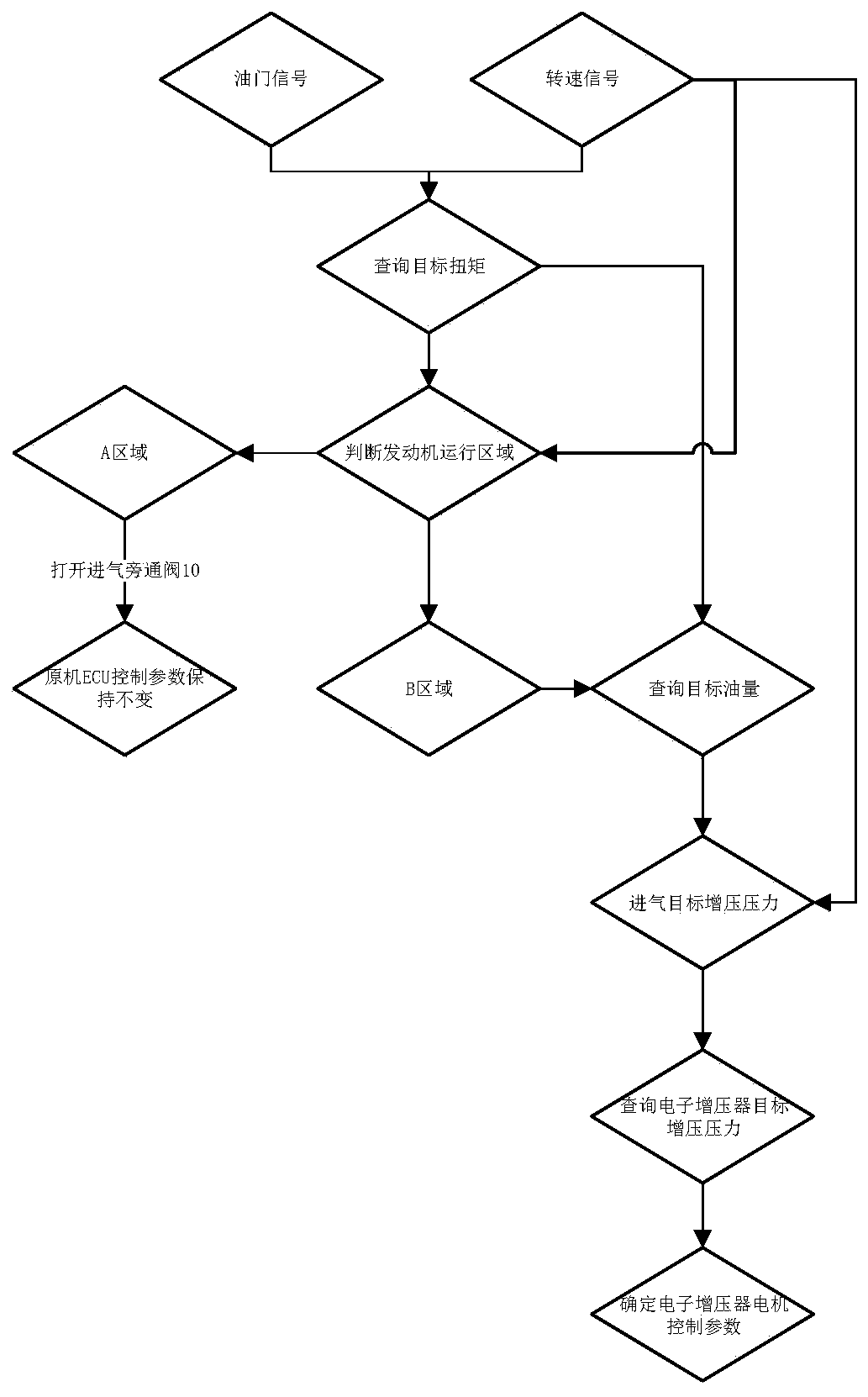

[0037] For the part of the improvement scheme proposed in this embodiment, refer to figure 1 , Figure 5 , the components included are exhaust gas turbocharger turbine 6, exhaust gas turbocharger compressor 7, electronic supercharger compressor 8, electronic supercharger actuator 9, intake bypass valve 10, intake bypass valve actuator 11.

[0038] The electronic supercharger is composed of an electronic supercharger compressor 8 and an electronic supercharger actuator 9 .

[0039] The exhaust gas turbocharger is composed of a wastegate 5 , an exhaust gas turbocharger turbine 6 , and an exhaust gas turbocharger compressor 7 .

[0040] Wherein, the blades of the exhaust gas turbocharger turbine 6 are coaxially connected with the blades of the exhaust gas turbocharger compressor 7, the blades of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com