Interlocking retaining nut

A nut and locking technology, applied in the direction of nuts, screws, bolts, etc., can solve problems such as equipment damage or even accidents, and increase maintenance cycle time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

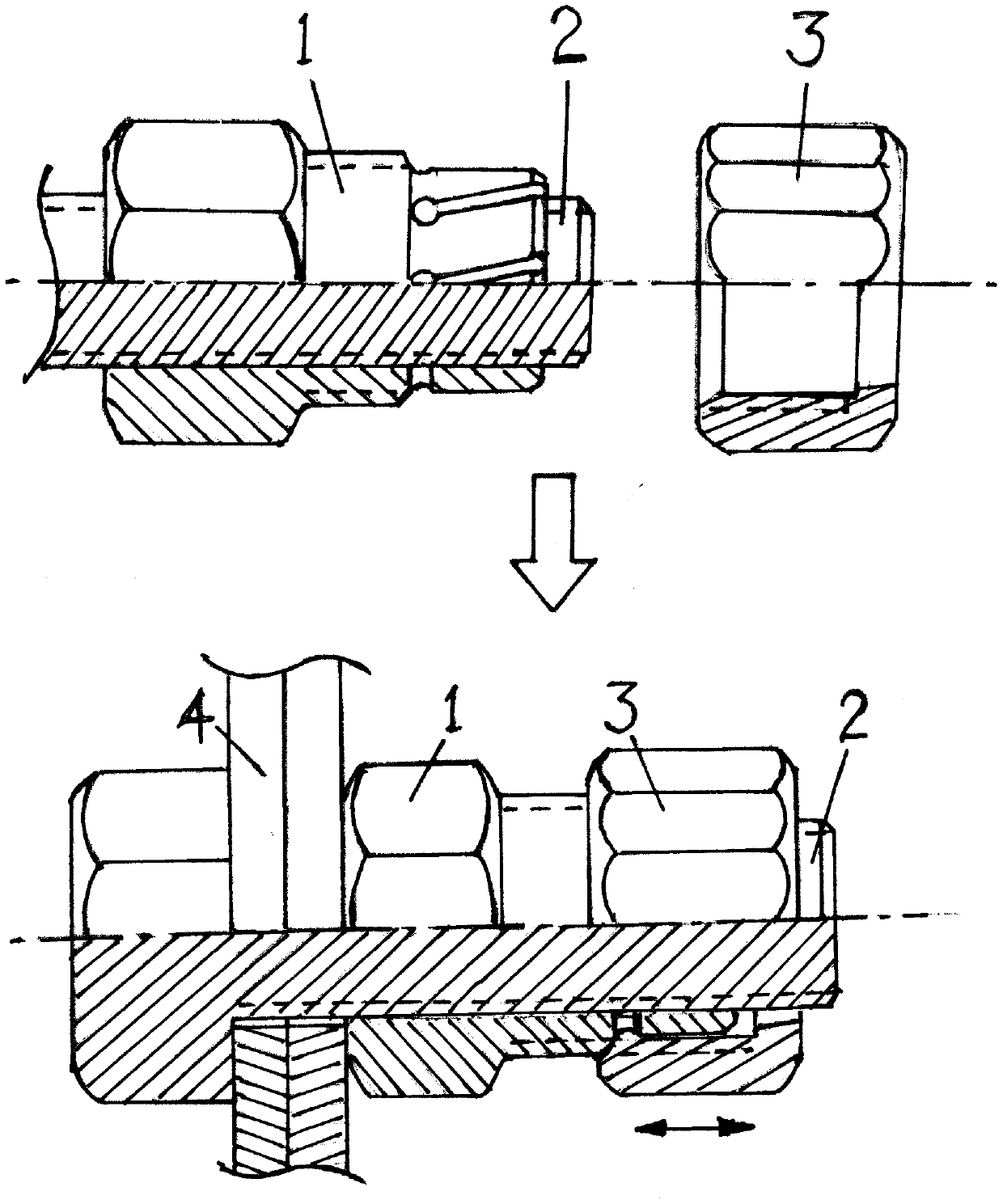

[0011] Embodiment 1: The process of stopping and releasing the stop-back of the three-step interlocking stop-back nut, see figure 1 .

[0012] figure 1 It is a schematic diagram of the shape and assembly relationship of the interlocking anti-retraction nuts of the three ladders. After the two assembly connection seats (4) are accurately positioned, the bolts (2) are threaded, and then the nut A (1) is tightened, and the nut A (1) is confirmed. After the tightness meets the requirements, tighten nut B(3) upwards on nut A(1). After confirming that the tightness of nut B(3) and nut A(1) meets the requirements, nut A(1), bolt (2) Nut A (1) and bolt (2) are bidirectionally interlocked between nut B(3), and nut A(1) and nut B(3) are bidirectionally interlocked. The three-part interlocking relationship is established. Finished, now the nut A (1), the bolt (2), and the nut (3) all have the back-stop function;

[0013] Nut B(3) makes nut A(1)'s small-diameter circular body with groo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com