Large-scale high-speed rotary equipment error measurement and separation method based on laser sensing

A technology of laser sensing and error measurement, which is applied in the direction of measuring devices, optical devices, complex mathematical operations, etc., can solve the problems of large errors, achieve the separation of errors, improve the accuracy, and improve the effect of measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

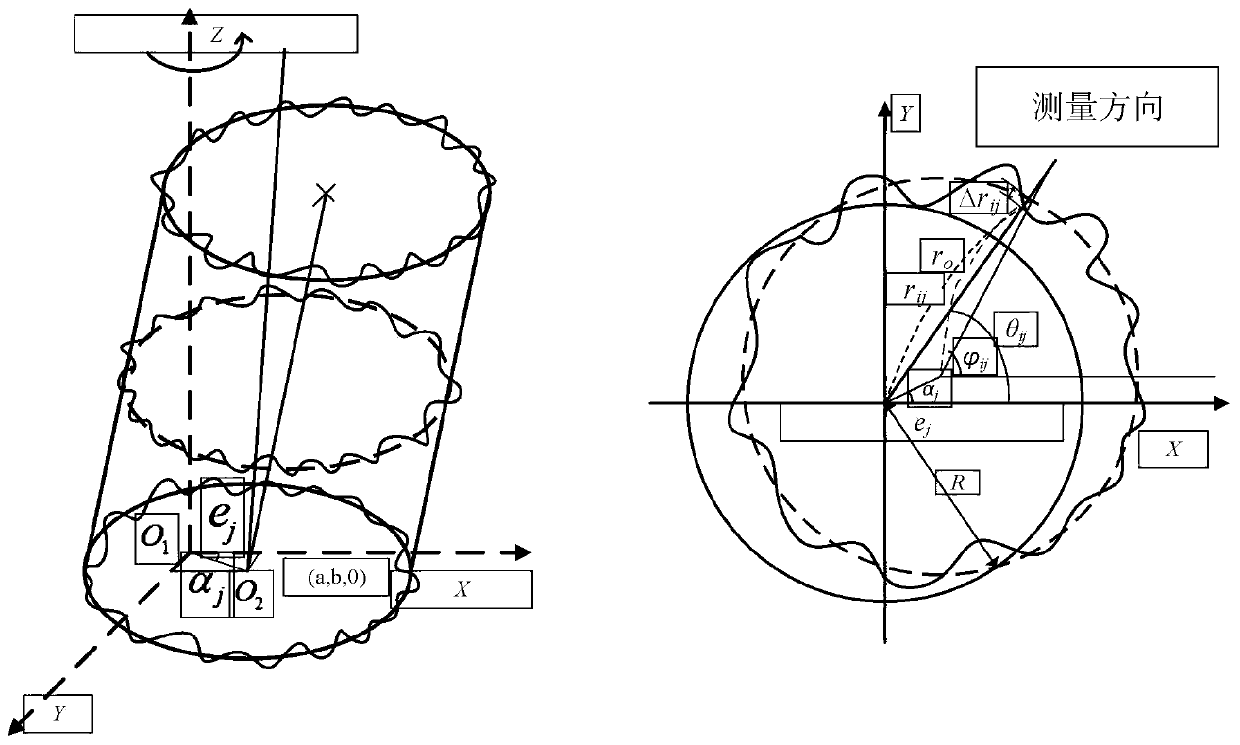

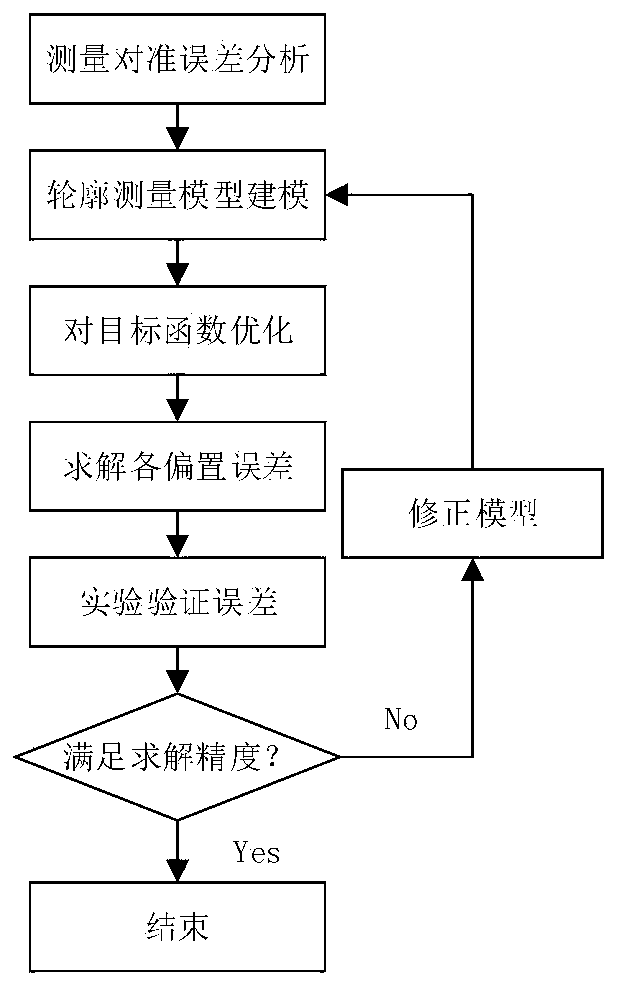

[0038] according to image 3 As shown, a large-scale high-speed rotary equipment error measurement and separation method based on laser sensing includes the following steps:

[0039] Step 1: Analyze the error of large-scale high-speed rotary equipment, and establish a large-scale high-speed rotary equipment error measurement model based on laser sensing;

[0040] The step 1 is specifically:

[0041] Step 1.1: Analyze the error of large-scale high-speed rotary equipment, determine the eccentricity error of large-scale high-speed rotary equipment, and express the eccentricity error of large-scale high-speed rotary equipment by the following formula:

[0042]

[0043] Among them, e j Eccentricity error for large high-speed rotary equipment, r ij is the measurement radius, θ ij is the sampling angle, α j is the eccentric angle, Δr ij is the processing error, j is the different section;

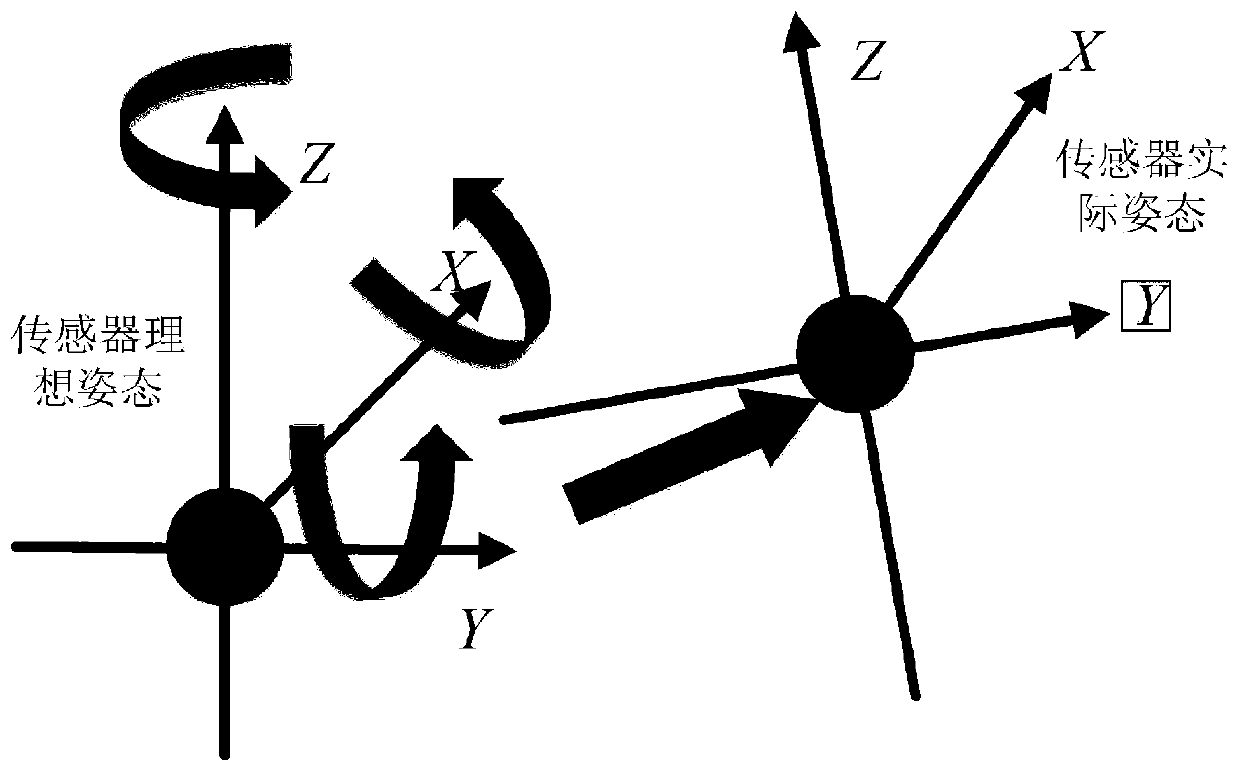

[0044] according to figure 2 As shown, step 1.2: determine the lateral offset erro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com