Longitudinal precise seedling conveying device and method

A seedling feeding and longitudinal technology, applied in the field of seedling feeding technology, can solve the problems of inaccurate positioning of the limit rod, poor adaptability of the seedling tray, inability to effectively clamp the bottom of the seedling tray, etc., and achieve the effect of convenient operation and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment one: Seedling delivery device

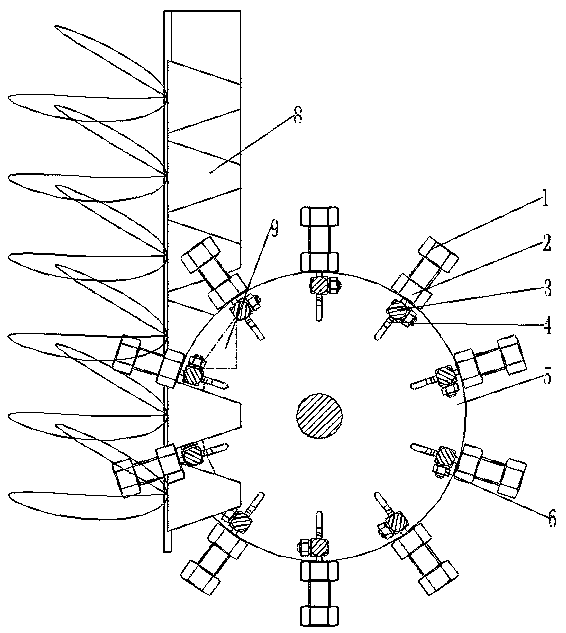

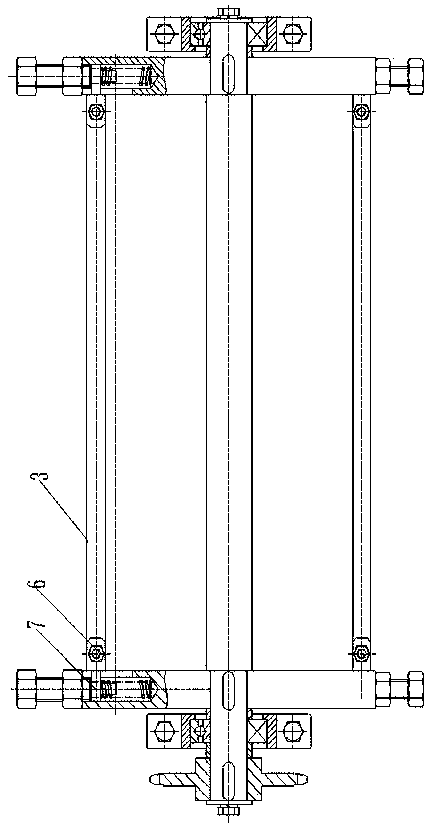

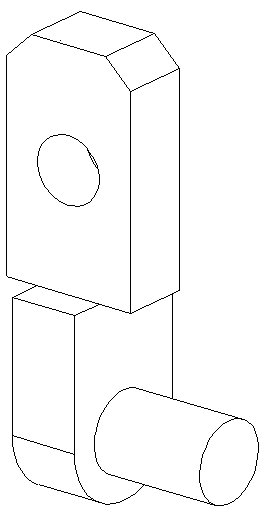

[0024] A vertical precision seedling delivery device, such as figure 1 or figure 2 As shown, it includes: adjusting screw 1, nut 2, limit rod 3, compression spring 4, mounting disc 5, bolt 6, cross slider 7. The structure of the cross slider 7 is as image 3 shown.

[0025] The limit rod 3 is fixedly connected to the round hole of the cross slider 7 through the bolt 6, and the cross slider 7 is slidably connected in the guide groove of the installation disc 5. The cylindrical convex end of the cross slider 7 is covered with a compression spring 4, and the compression spring 4 Installed in the guide groove; the flat end of the cross slider 7 is engaged with the adjustment screw 1; when the adjustment screw 1 is tightened downward, the screw 1 acts on the flat end of the cross slider 7, and the linkage limit rod 3 moves downward radially When the adjusting screw 1 is loosened, the limit rod moves upward in the radial directi...

Embodiment 2

[0027] Embodiment two: send seedling process (tomato seedling)

[0028] Process 1: Start the vertical seedling delivery device, and after the seedling raising tray 8 is fed, it moves down under the action of gravity until the lower end of the outer surface of the first row of hole pots contacts with the limit rod 3; , the vertical and precise seedling delivery device drives the seedling tray to move downward, and the transfer distance is realized by rotating the angle of the installation disc 5, which is similar to the rack and pinion mechanism; there is a triangle staggered between the adjacent limit rod 3 and the seedling tray 8 The space 9 makes the stop bar 3 better positioned at the bottom of the seedling tray 8;

[0029] Process 2, the installation disk 5 is rotated counterclockwise so that the limit rod 3 gradually enters the outside of the seedling tray and is positioned at the bottom of the upper groove. When the limit rod 3 reaches the bottom of the seedling tray 8 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com