Feeding box for silkworms, rearing apparatus for silkworms, and integrated machine for automatic rearing of small silkworms

A technology of feeding box and all-in-one machine, applied in animal husbandry and other directions, can solve the problems of time-consuming, labor-intensive, low-efficiency, etc., and achieve the effect of saving time and labor cost, reducing labor intensity and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

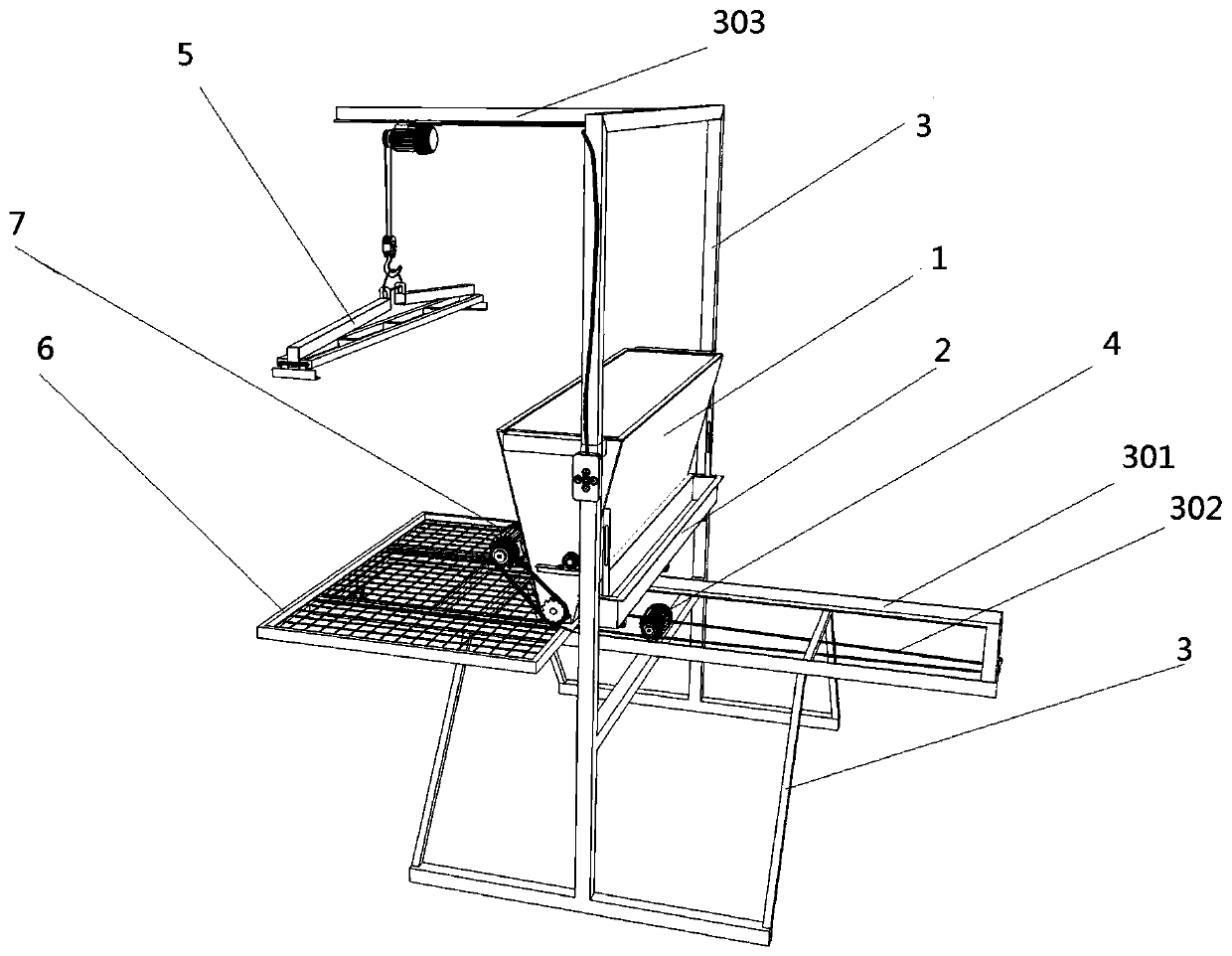

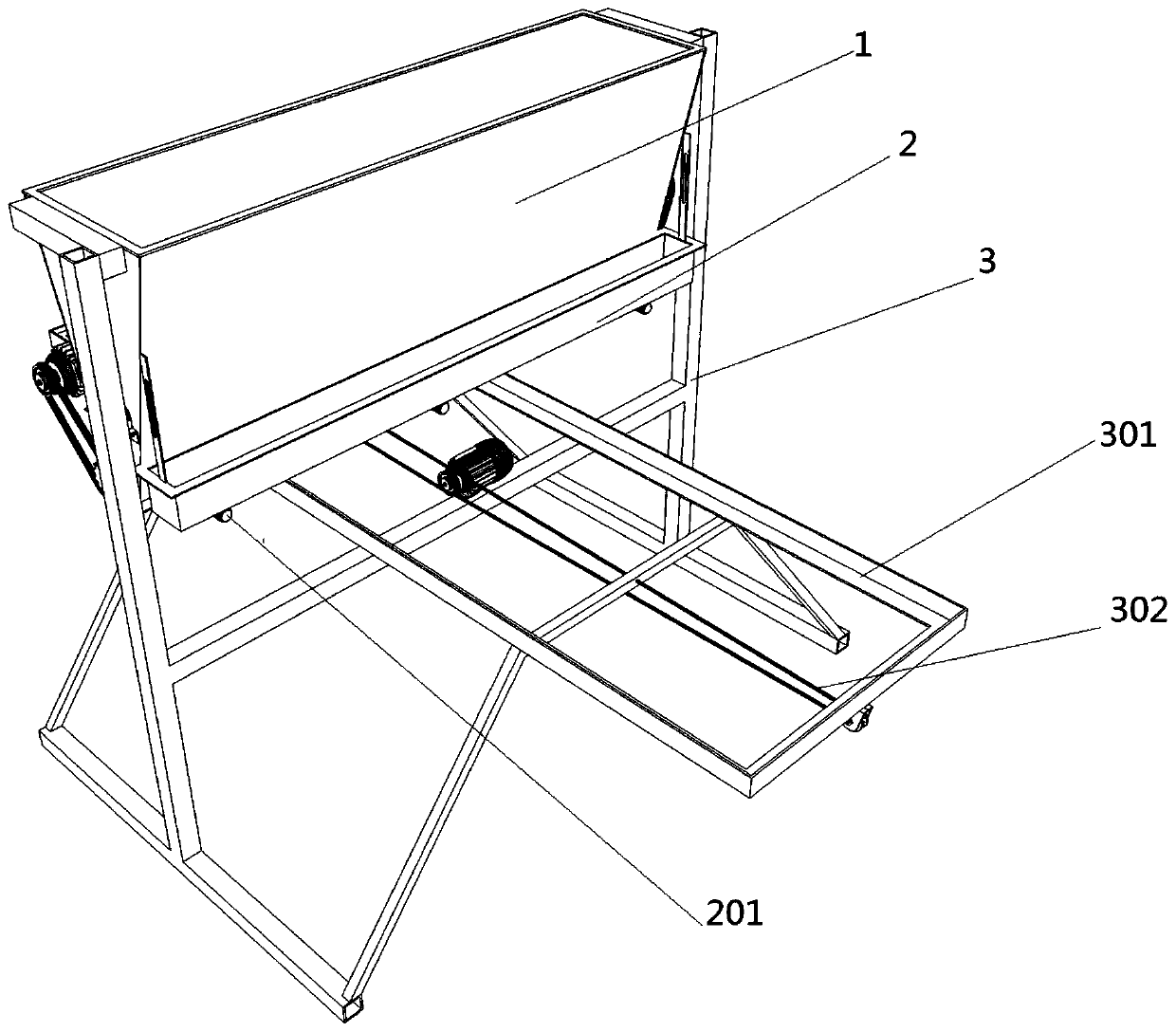

Embodiment 1

[0020] Embodiment one, the embodiment of feeding box for silkworms. The feeding box for silkworms of the present invention comprises a main box and an auxiliary box, the main box and the auxiliary box can be connected as a whole, and can also be separated independently. Narrow, set two rotating shafts at the lower mouth, the upper shaft is equipped with a hard material toggle nail, and the lower shaft is equipped with a brush of soft material to prevent the mulberry leaves from forming an arch in the main box and not falling. The upper shaft rotates the handle The mulberry leaves are raked downward to the lower shaft to achieve the purpose of continuous feeding, and the lower shaft rotates to evenly pull the mulberry leaves out of the lower box opening; the auxiliary box is a box containing lime, and the lower port is equipped with a mesh screen and a vibrating motor. The purpose is to sprinkle lime to disinfect silkworm bodies and silkworm winnowing, see figure 2 , diagra...

Embodiment 2

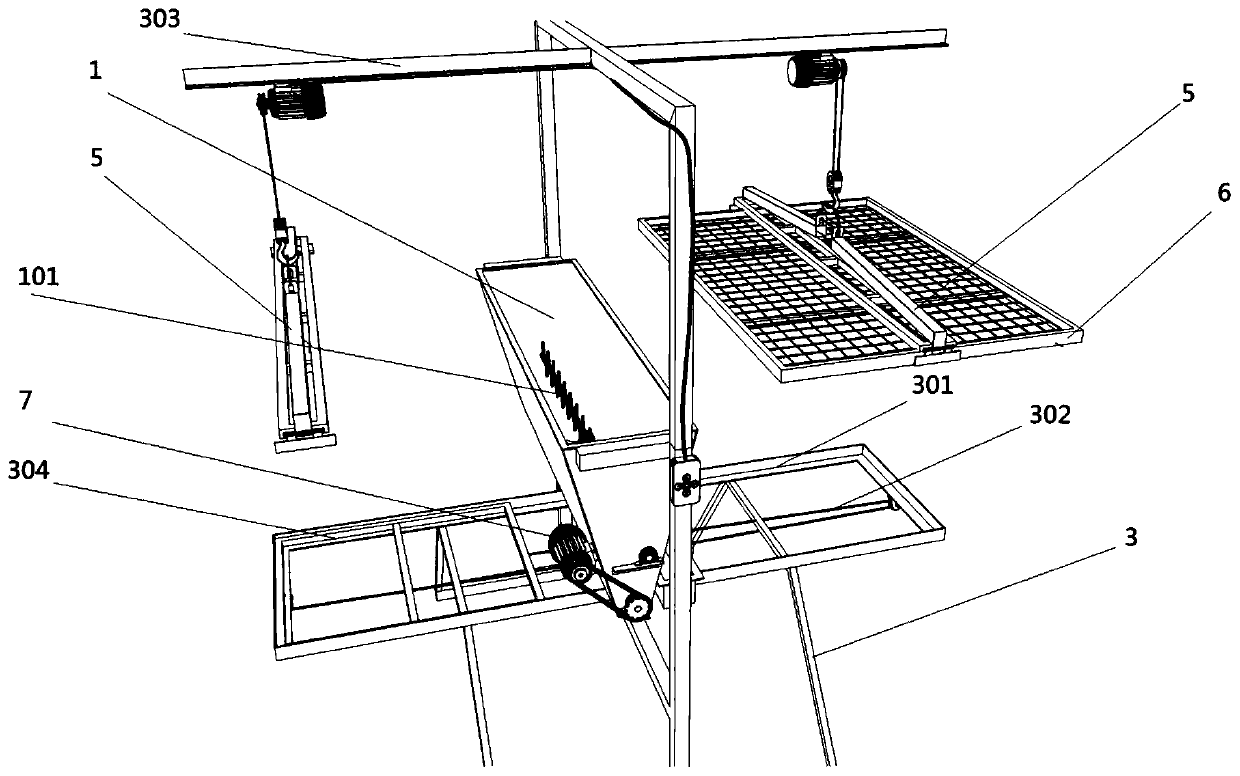

[0021] Embodiment two, silkworm rearing device example. Set the chute, sliding frame, motor and wire rope for pulling on the frame, see image 3 , take each component of embodiment one, according to diagram 2-1 , Figure 2-2 , Figure 2-3 hooked up on the rack, got figure 2 In the same way, the switch, two travel limit switches and the light control switch circuit are connected together to form a silkworm rearing device. Put mulberry leaves and lime in the main box and the auxiliary box respectively. When the mulberry leaves need to be fed, put the silkworm dustpan filled with small silkworms in the sliding frame, start the power supply, and the first motor pulls the sliding frame through the steel wire rope, and the sliding frame is convenient. Sliding in the chute, the silkworms also slide. When the silkworms pass under the main box, the light control switch of the main box is activated, and the signal is sent to the speed-regulating motor of the main box, and the spee...

Embodiment 3

[0024] Embodiment 3, an example of an all-in-one machine for automatic feeding of silkworms. Above-mentioned example two has the effect of giving leaves and disinfecting, but cannot pile up or move the silkworm dust. In this example, on the basis of Example 2, two vertical bars are respectively welded on both sides of the frame, and a cross bar is connected between the two vertical bars. 3 meters high, made as Pic 4-1 The clamping assembly, the width that the clamping assembly can clamp is equal to the width of a set of opposite sides of the silkworm dust. The clamping width of this example is 1.5 meters, and the width can be adjusted according to the specifications of the silkworm dust. Clamping arm, when the claws need to be fine-tuned to hold the silkworm, the size of the hinge can be adjusted, lift the clamping bar upwards, and transmit the pulling force through a pair of clamping arms, and the pair of claws will shrink and clamp the silkworm. When putting down the clam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com