Finish machining and finish polishing process

A processing technology and precision polishing technology, which is used in the field of finishing to achieve the effects of increasing durability, increasing wear resistance, and increasing dimensional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

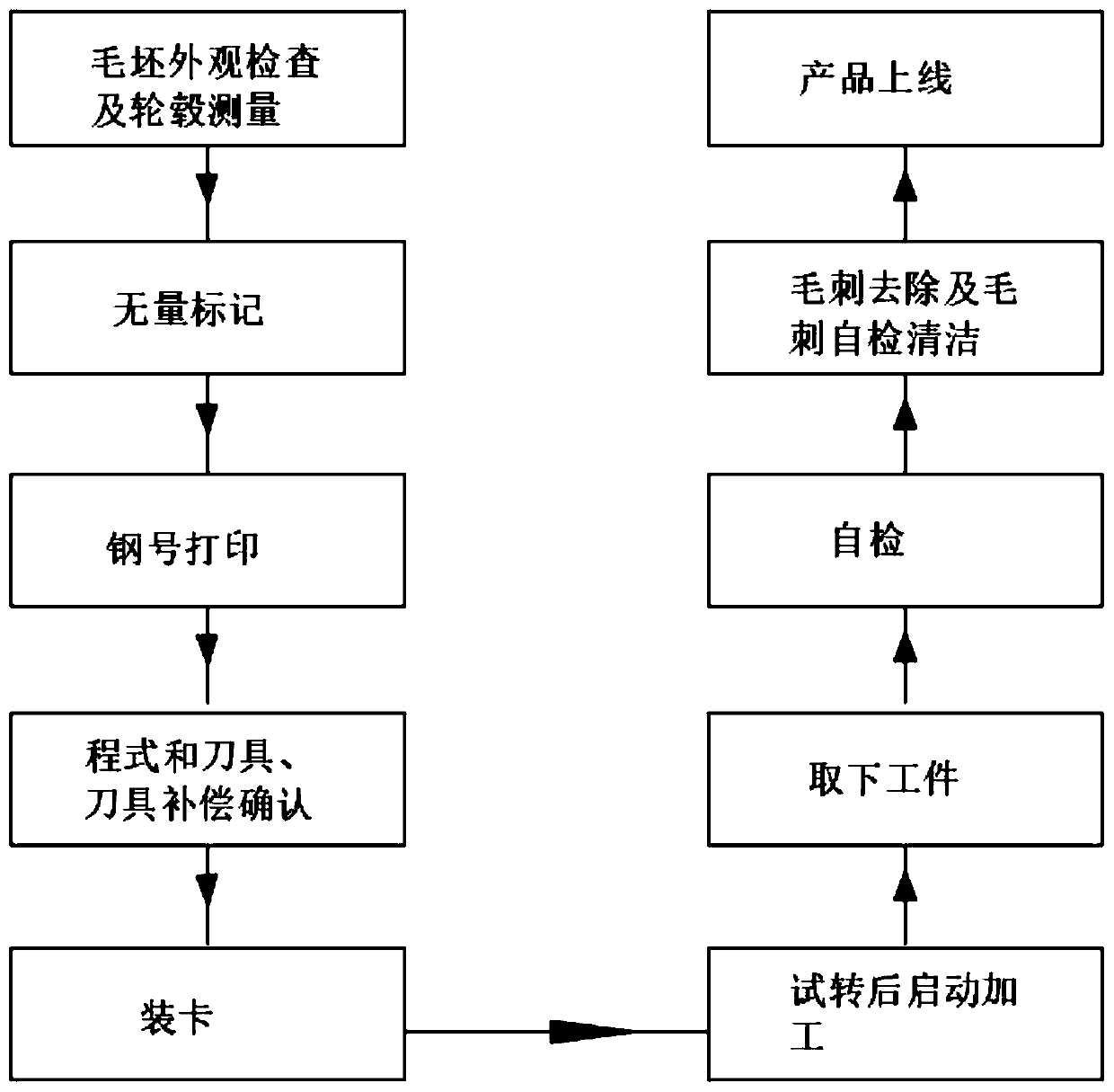

[0019] Below in conjunction with accompanying drawing, the present invention is described in detail, a kind of finish machining fine polishing process, as figure 1 shown, including the following steps:

[0020] Step One: Check the Measurements. 100% inspection of the appearance of semi-finished products, separate stacking of unqualified products in standard definition, and 100% measurement of wheel width processing of semi-finished products;

[0021] The second step: infinite mark. Before finishing turning, after measuring with a measuring tool, it is judged as a product that can be processed, but there is no repair allowance, use a paint pen to touch the weight-reducing pocket of the back cavity, and confirm that it is an infinite repair product;

[0022] The third step: steel number printing. For the semi-finished products that meet the processing requirements, print the marking numbers in sequence;

[0023] Step 4: Confirm the program. Before processing the first piece...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com