AGV equipment-based double-multiplying-power barrel type lifting multi-stage electric cylinder

An electric cylinder and magnification technology, applied in the direction of hoisting device, can solve the problems of high precision processing and manufacturing, low degree of independent intellectual property rights, difficult manufacturing and assembly, etc., achieving obvious price advantages and high degree of independent intellectual property rights of products. , the best performance of the whole machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

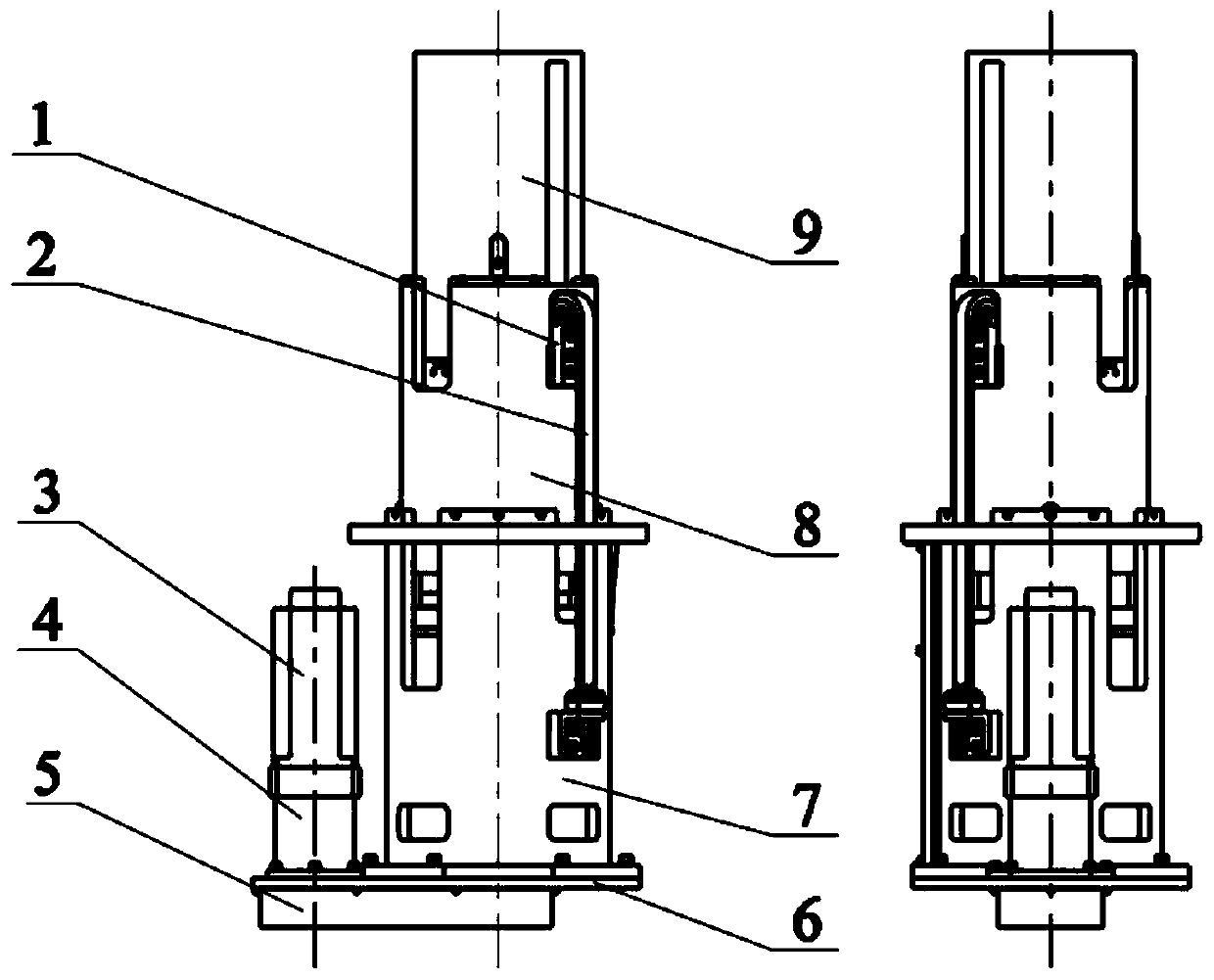

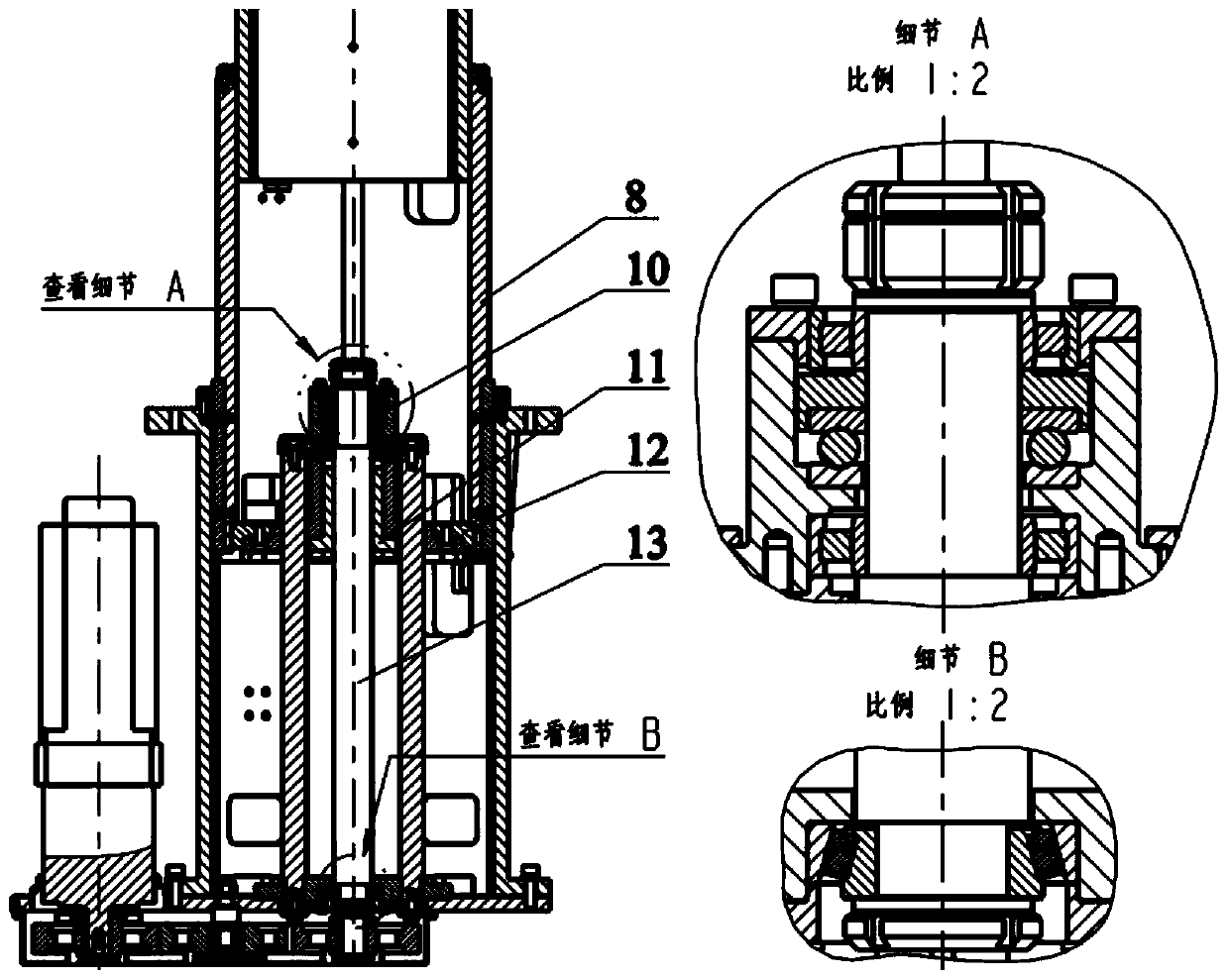

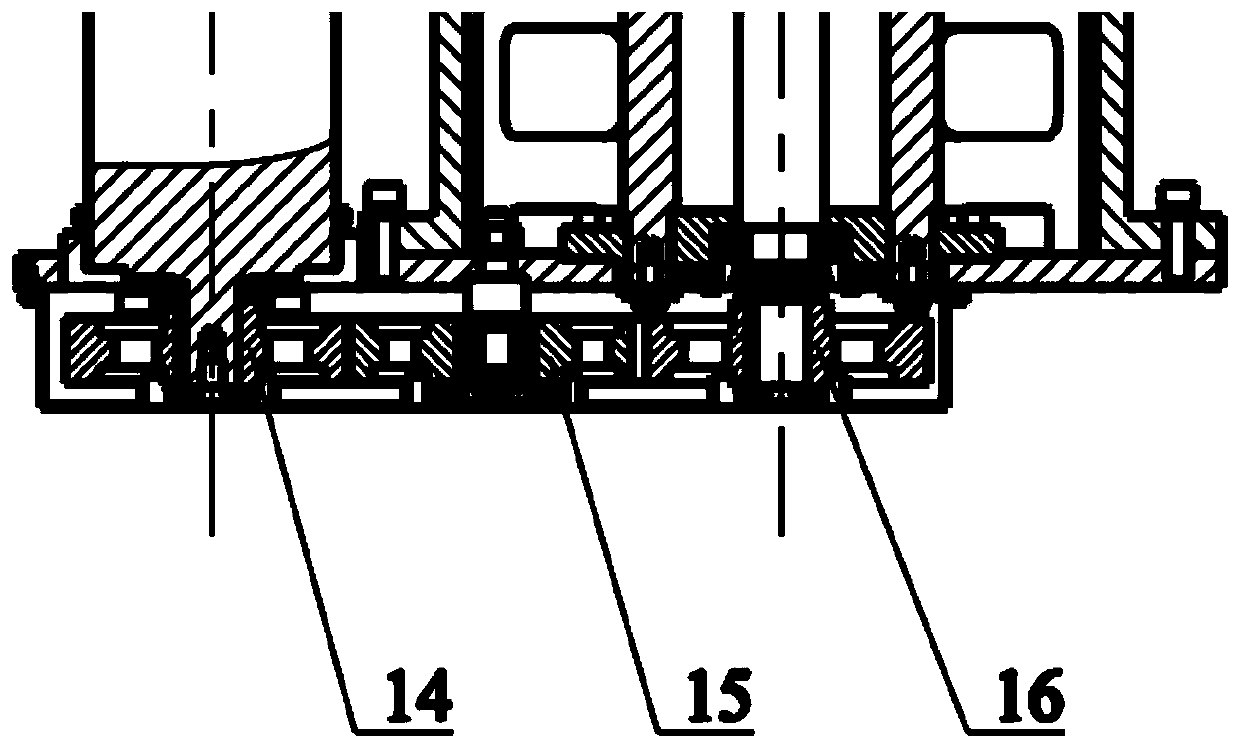

[0031] A double-rate cylinder-type lifting multi-stage electric cylinder based on AGV equipment, the electric cylinder includes a movable pulley block 1, a chain 2, a servo motor 3, a planetary reducer 4, a gearbox 5, an installation base plate 6, and an outer fixed cylinder 7. Primary cylinder 8, secondary cylinder 9, bearing assembly 10, screw nut 11, adapter flange 12, ball screw shaft 13, driving gear 14, intermediate gear 15, driven gear 16, zero position Proximity switch 17, lower limit proximity switch 18, upper limit proximity switch 19.

[0032] Such as figure 1 As shown, the output shaft of the servo motor 3 is connected to the input shaft of the planetary reducer 4. When the output shaft of the servo motor 3 rotates, it drives the input shaft of the planetary reducer 4 to rotate, and a series of gear meshing transmissions inside the planetary reducer 4 , to drive the output shaft of the planetary reducer 4 to rotate.

[0033] Such as figure 1 and image 3 As sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com