Double-layer passivation film material and preparation method thereof

A passivation film and double-layer technology, which is applied to laser parts, semiconductor lasers, electrical components, etc., can solve the problems of poor passivation effect, poor reliability, and unstable process, and achieve small interface stress, not easy to fall off, light The effect of good transmission characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

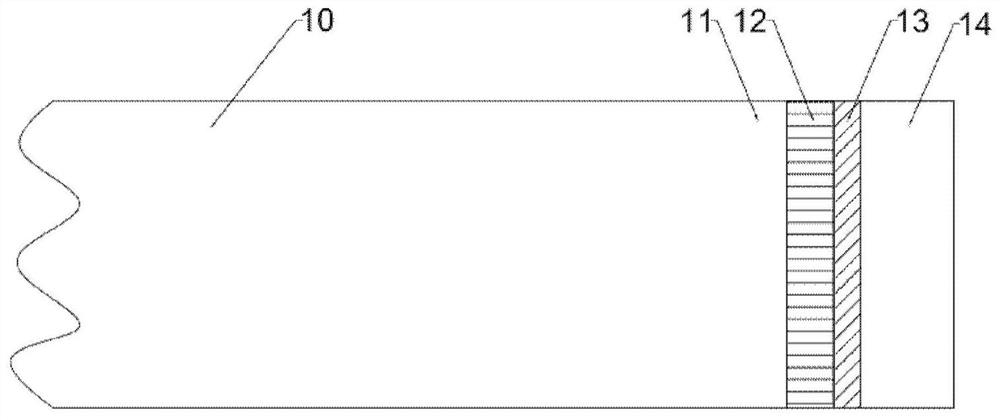

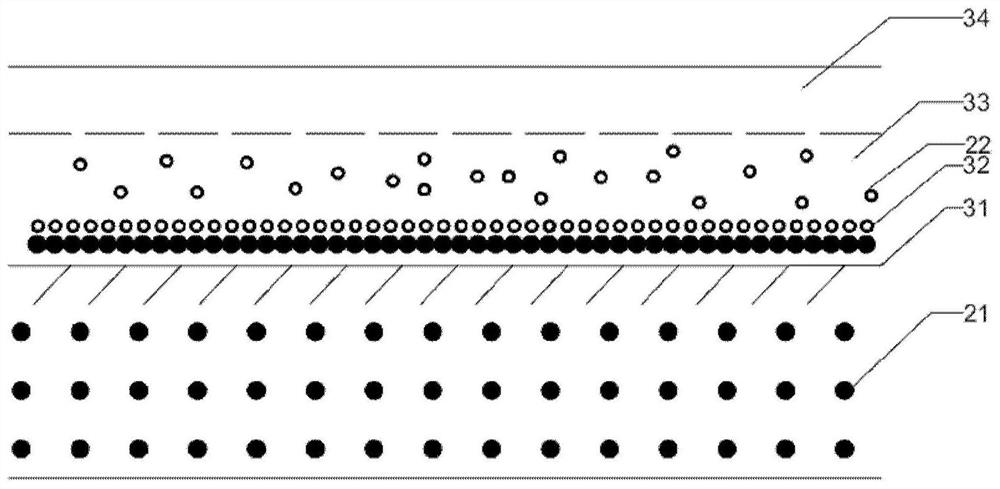

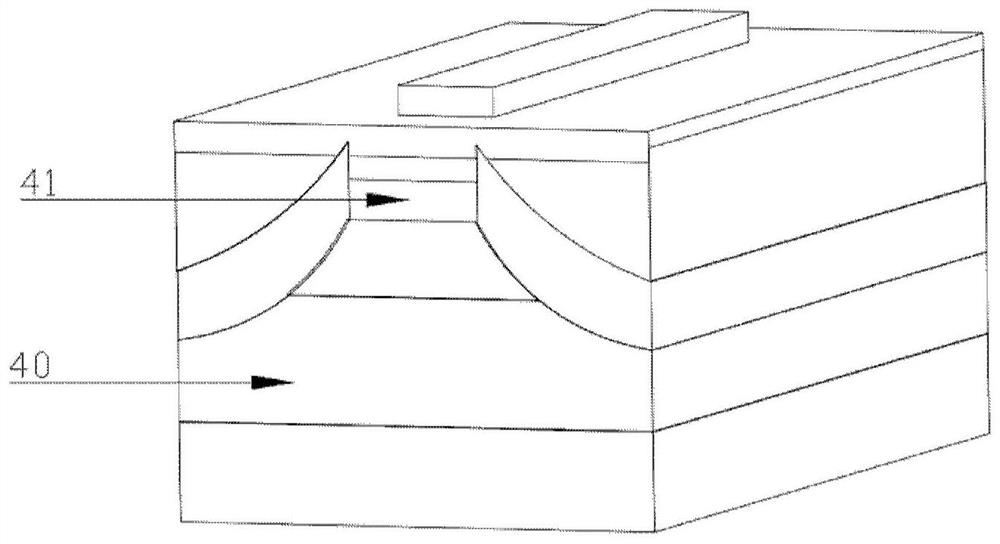

[0042] The disclosure provides a double-layer passivation film material and a preparation method thereof, using GaN and TiO with excellent performance 2 Passivation materials, develop new passivation structures, and change the passivation structures that rely on plating a single-structure passivation film in the past. The object of the present invention is to provide a double-layer film passivation structure and its preparation method, which can greatly reduce the surface state density at the cavity surface of the laser, while controlling the process difficulty and cost at a low level.

[0043] GaN belongs to group III-V compound semiconductor materials, and its forbidden band width Eg=3.4eV is much higher than that of GaAs (Eg=1.42eV). GaN film has many excellent physical and chemical properties: (1) High thermal conductivity (about 500W / mK), much higher than the existing passivation film AlN (about 300W / mK), ZnO (about 6W / mK), far Higher than the thermal conductivity of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com