Dyed silk fabric manufacturing process

A manufacturing process and silk fabric technology, applied in the field of dyeing silk fabric manufacturing process, can solve the problems of poor color brightness of textile fabrics, complicated preparation method, unfavorable promotion, etc., and achieve the effects of less color fading, high whiteness, and easy dyeing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

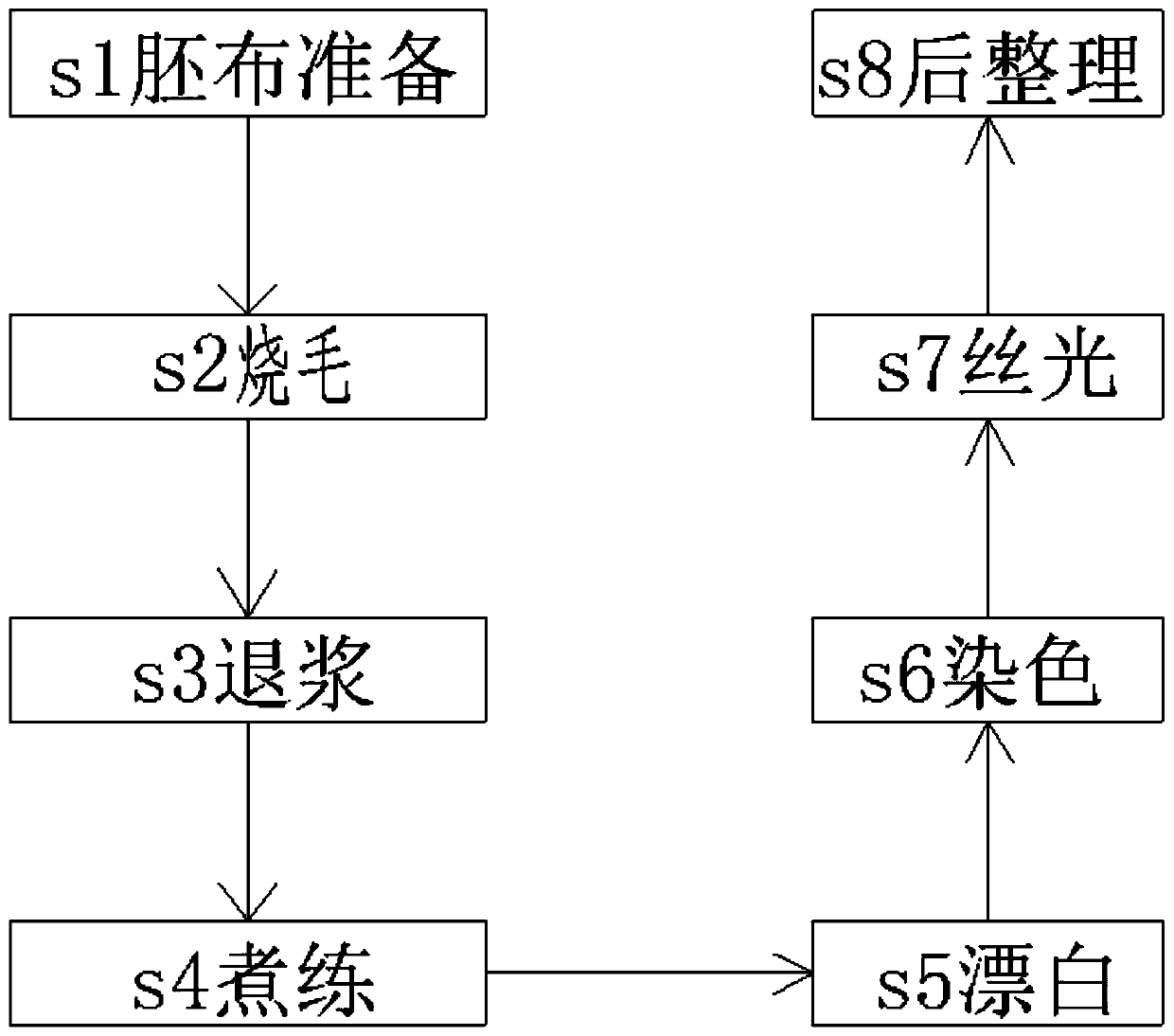

Image

Examples

Embodiment 1

[0034] A kind of dyed silk fabric manufacturing process is characterized in that comprising the steps:

[0035] s1. Gray cloth preparation:

[0036] Gray cloth preparation includes gray cloth inspection, cloth turning (batch, binning, printing) and seam head. The purpose of the gray cloth inspection is to check the quality of the gray cloth, and to solve the problems in time. The inspection content includes two items of physical indicators and appearance defects. The former includes the length, width, weight, warp and weft yarn density, strength, etc. of the gray cloth, while the latter includes spinning defects, weaving defects, various stains and damages. Usually about 10% of the total amount of spot checks. After the gray cloth is inspected, the gray cloth must be divided into batches and boxes, and printed on the head of the cloth, indicating the variety, processing technology, batch number, box number, release date and the code of the person who turned the cloth, so as...

Embodiment 2

[0053] A kind of dyed silk fabric manufacturing process is characterized in that comprising the steps:

[0054] s1. Gray cloth preparation:

[0055] Gray cloth preparation includes gray cloth inspection, cloth turning (batch, binning, printing) and seam head. The purpose of the gray cloth inspection is to check the quality of the gray cloth, and to solve the problems in time. The inspection content includes two items of physical indicators and appearance defects. The former includes the length, width, weight, warp and weft yarn density, strength, etc. of the gray cloth, while the latter includes spinning defects, weaving defects, various stains and damages. Usually about 10% of the total amount of spot checks. After the gray cloth is inspected, the gray cloth must be divided into batches and boxes, and printed on the head of the cloth, indicating the variety, processing technology, batch number, box number, release date and the code of the person who turned the cloth, so as...

Embodiment 3

[0072] A kind of dyed silk fabric manufacturing process is characterized in that comprising the steps:

[0073] s1. Gray cloth preparation:

[0074] Gray cloth preparation includes gray cloth inspection, cloth turning (batch, binning, printing) and seam head. The purpose of the gray cloth inspection is to check the quality of the gray cloth, and to solve the problems in time. The inspection content includes two items of physical indicators and appearance defects. The former includes the length, width, weight, warp and weft yarn density, strength, etc. of the gray cloth, while the latter includes spinning defects, weaving defects, various stains and damages. Usually about 10% of the total amount of spot checks. After the gray cloth is inspected, the gray cloth must be divided into batches and boxes, and printed on the head of the cloth, indicating the variety, processing technology, batch number, box number, release date and the code of the person who turned the cloth, so as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com