A kind of flame-retardant wallpaper base paper and preparation method thereof

A technology of base paper and wallpaper, which is applied in the field of flame-retardant wallpaper base paper and its preparation, can solve the problems of unsustainable flame-retardant effect, yellowing and darkening of whiteness, and reduced flame-retardant performance of wallpaper base paper, and achieve outstanding market competition force, reduce the loss of paper, and improve the effect of surface strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

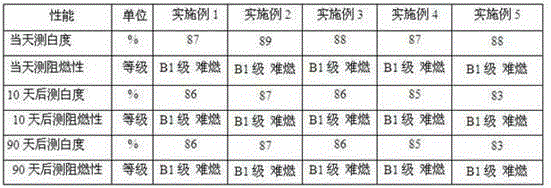

[0027] Embodiments 1 to 5 are specific implementations of the flame-retardant wallpaper base paper of the present invention and its preparation method, wherein embodiment 1 is the best embodiment.

[0028] Example 1

[0029] In this example, the proportion of components is 65 parts by weight of softwood pulp fiber, 18 parts of chemical fiber is polyethylene terephthalate fiber, 10 parts of acrylic latex, and the flame retardant trishydroxymethyl phosphorus oxide (THPO) 2 parts, the modifier is 2 parts of dimethyl tin oxide and dibutyl tin dichloride mixed according to the mass ratio of 1:1, 0.2 parts of cationic polyacrylamide, 0.2 parts of wet strength agent PAE, fluorescent whitening agent BBU0 .08 servings.

[0030] The preparation method of the present embodiment is as follows:

[0031] a) Mix wood pulp fiber and chemical fiber in proportion, use a pulper to finely grind and decompose and beat, the beating degree is 29°SR, and the beating concentration is controlled at ...

Embodiment 2

[0037] In this example, the component distribution ratio is 70 parts of hardwood pulp fiber, 17 parts of nylon fiber, 15 parts of acrylic latex, 3 parts of flame retardant diphenyl phosphate (BDP), and 1 part of dimethyl tin oxide as a modifier , 0.1 part of dry strength agent chitosan, 0.5 part of wet strength agent PAE, and 0.2 part of fluorescent whitening agent BA-L.

[0038] The preparation method of the present embodiment is as follows:

[0039] a) Mix wood pulp fiber and chemical fiber in proportion, use a pulper to finely grind and decompose and beat, the beating degree is 30°SR, and the beating concentration is controlled at 2%;

[0040] b) Add dry strength agent, wet strength agent PAE and 1 part of water to the pulper for batching, adjust the pH value to 7 to form a mixed fiber slurry, and make and dry the base paper by fourdrinier paper machine semi-finished products;

[0041] c) Mix and stir the flame retardant and the modifier according to the mass ratio to obt...

Embodiment 3

[0045]In this embodiment, the component distribution ratio is in parts by weight, 70 parts of softwood pulp fibers and hardwood pulp fibers are mixed in a mass ratio of 3:1, 15 parts of chemical fibers are nylon fibers, 10 parts of acrylic latex, and the flame retardant trimethylol Phosphorus oxide (THPO) 3 parts, modifier is 1 part of dibutyl tin dichloride, dry strength agent guar gum 0.5 part, wet strength agent PAE 0.1 part, and fluorescent whitening agent BBU and fluorescent whitening agent Mix 0.15 parts of BA-L according to the mass ratio of 1:1.

[0046] The preparation method of the present embodiment is as follows:

[0047] a) Mix wood pulp fiber and chemical fiber in proportion, use a pulper to finely grind, decompose and beat, the beating degree is 32°SR, and the beating concentration is controlled at 3%;

[0048] b) Add dry strength agent, wet strength agent PAE and 2 parts of water to the pulper for batching, adjust the pH value to 8 to form a mixed fiber slurry...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com