Subway tunnel wall cleaning operation vehicle and cleaning operation method

A technology for tunnel walls and working vehicles, applied in cleaning methods, road cleaning, construction, etc., can solve problems such as poor dirt collection capacity, increase vehicle mobility, manual cleaning, etc., to avoid secondary pollution and avoid secondary dust. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

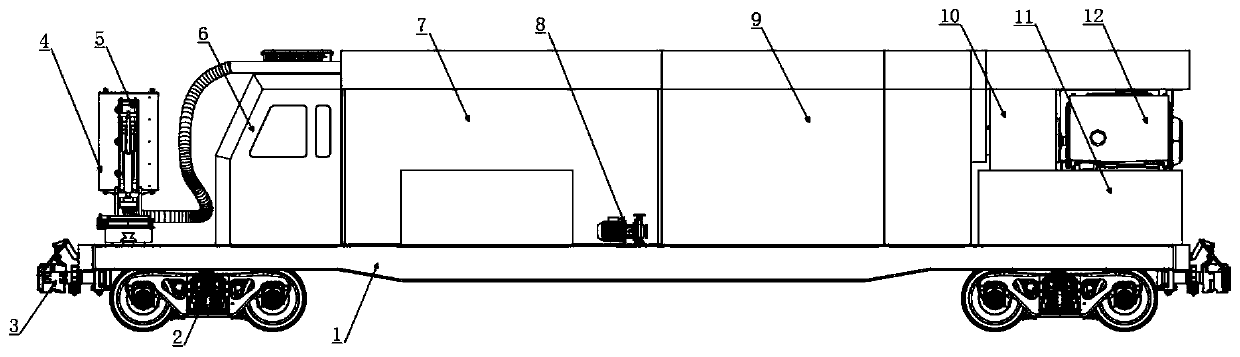

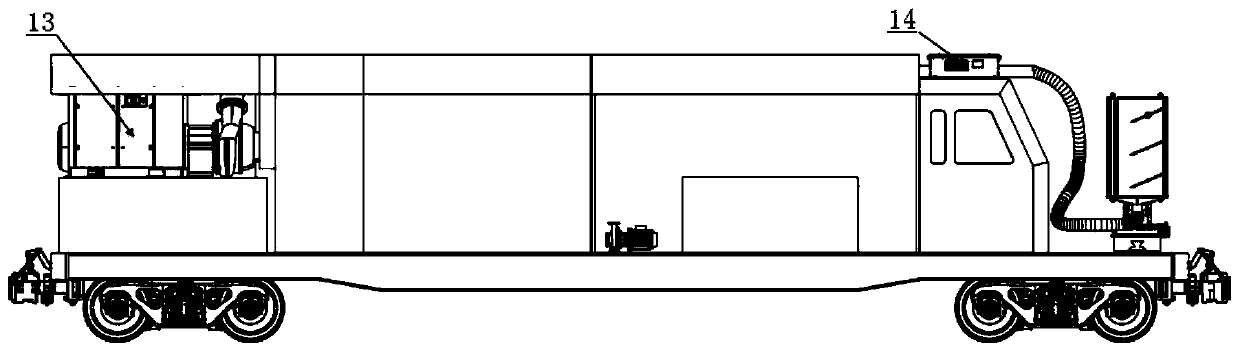

[0053] Such as Figure 1 to Figure 5 As shown, a subway tunnel wall cleaning vehicle includes a bogie 2, a vehicle frame 1, and a coupler 3, the vehicle frame 1 is arranged on the bogie 2, and the vehicle coupler 3 is arranged on the vehicle frame 1 , also includes cleaning device 4 and mechanical arm 5, and described mechanical arm 5 is placed on described vehicle frame 1, and is connected with described cleaning device 4, is used for adjusting the position of described cleaning device 4 through described mechanical arm 5 , to clean the corresponding position of the tunnel wall.

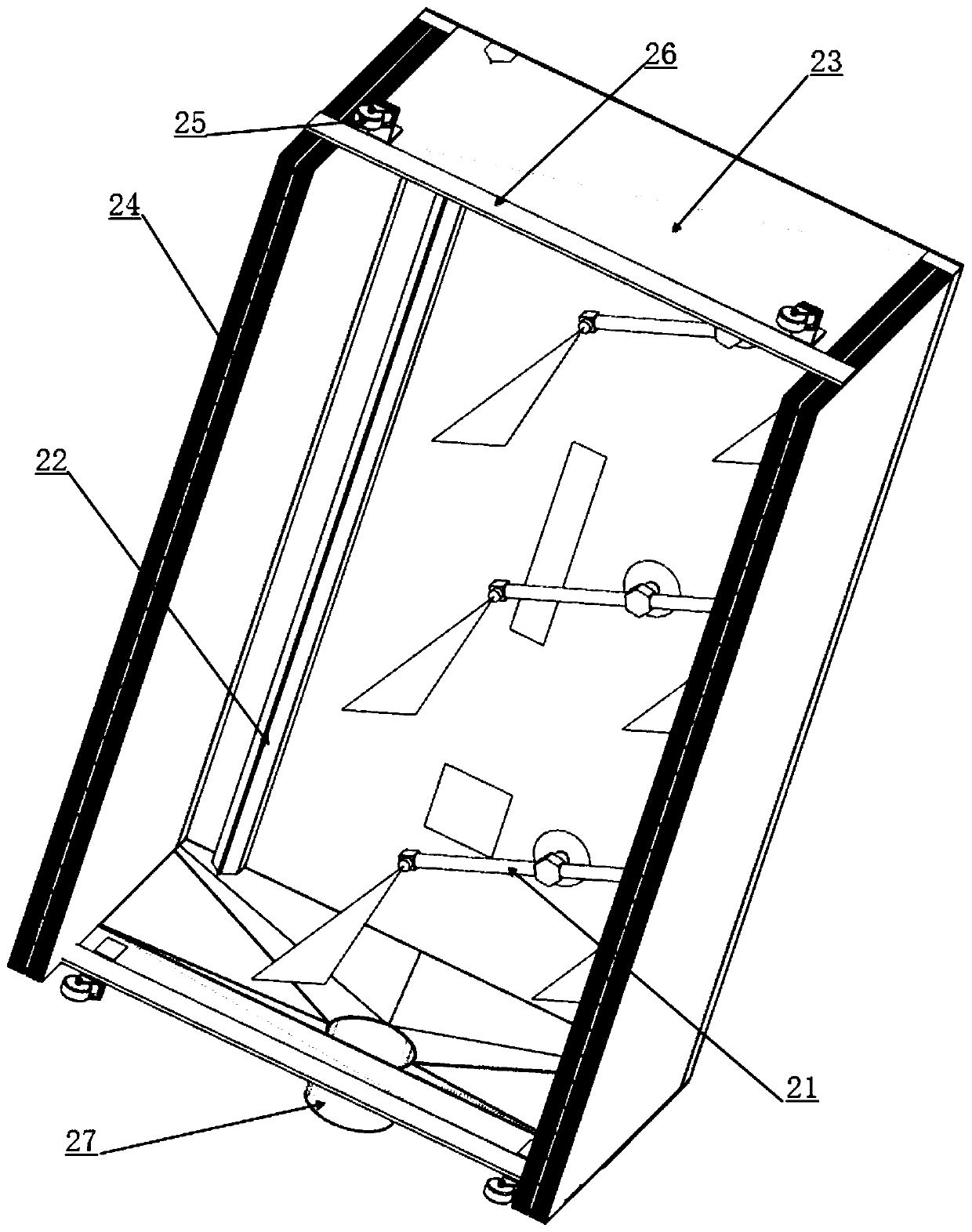

[0054] The cleaning device 4 includes a rotary washing device 21 and an air knife 22 . The rotary flushing device 21 includes a nozzle, a rotating rod and a rotating body, the rotating rod is connected to the rotating body, and the nozzles are arranged at both ends of the rotating rod. The cleaning device 4 is provided with three sets of the rotary flushing devices 21 . A cleaning cover 23 is pro...

Embodiment 2

[0059] The difference from Embodiment 1 is that the cleaning device 4 is provided with at least one set of the rotary flushing device 21 .

Embodiment 3

[0061] A cleaning operation method for a subway tunnel wall cleaning vehicle, used for the cleaning operation vehicle to clean the subway tunnel wall, comprising:

[0062] In the operation room 6, the action of the mechanical arm 5 is controlled by the control button on the console, so that the universal wheel 25 on the cleaning device 4 is in contact with the wall of the subway tunnel;

[0063] The rotary flushing device 21 flushes the subway tunnel wall;

[0064] The dirt collection and treatment device 9 sucks and collects the sewage with dirt generated by the flushing operation, and filters and stores it;

[0065] The air compressor system 13 provides compressed air for the air knife to dry and clean the subway tunnel wall;

[0066] The rail car pulls the cleaning vehicle along the working section to complete the cleaning operation of the subway tunnel wall.

[0067] In this embodiment, the water pump pressurizes the water output from the water storage tank, and the high...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com