Membrane type microcapillary precooler cooling refrigerant gas collecting device

A technology for cooling working fluid and gas collecting devices, which is applied in the direction of machines/engines, internal combustion piston engines, mechanical equipment, etc., and can solve the problems of large flow resistance, many sealing parts, large volume and weight of the precooler, and improve the structure Reliability, improve the overall rigidity, and reduce the effect of process difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below with reference to the accompanying drawings and examples.

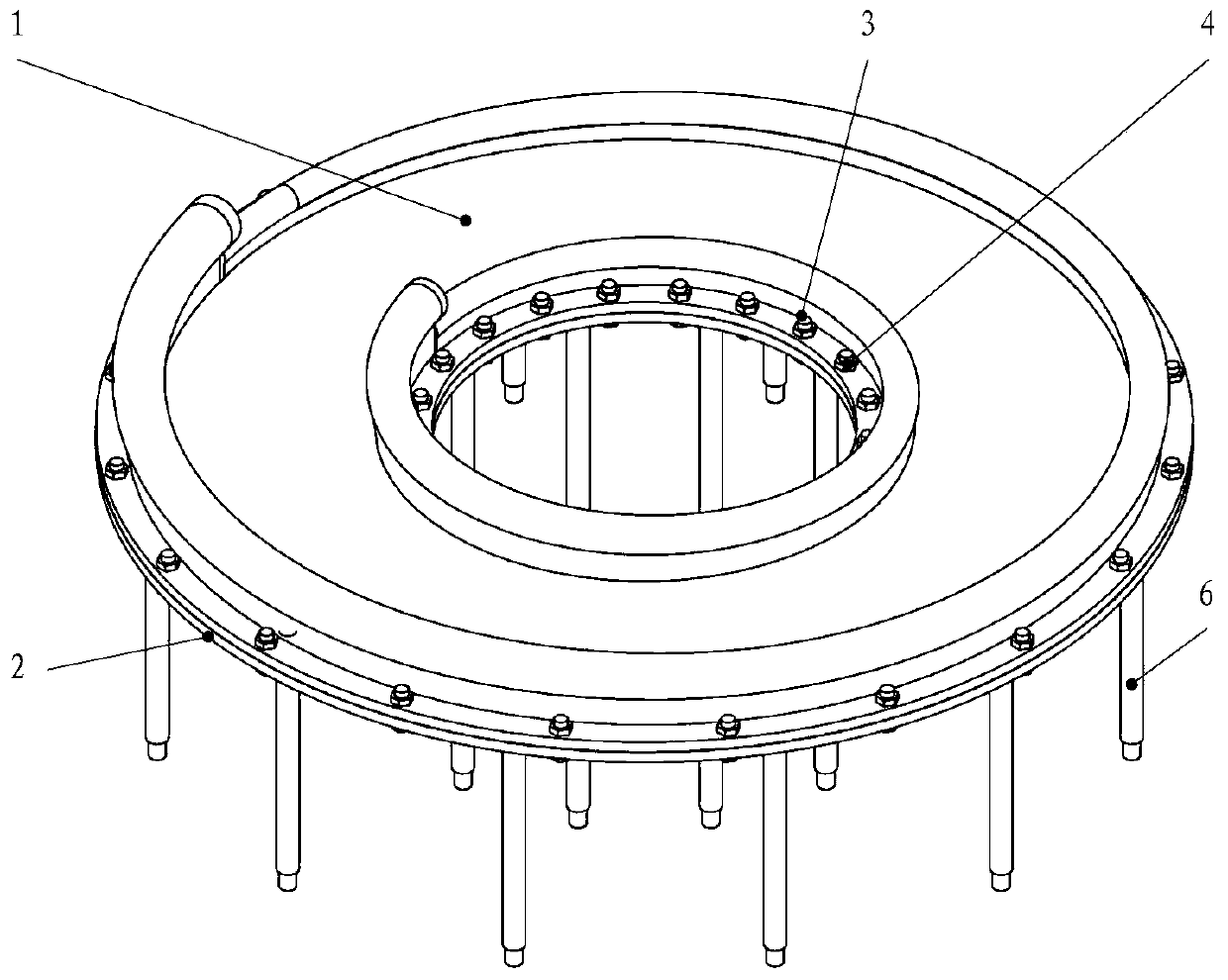

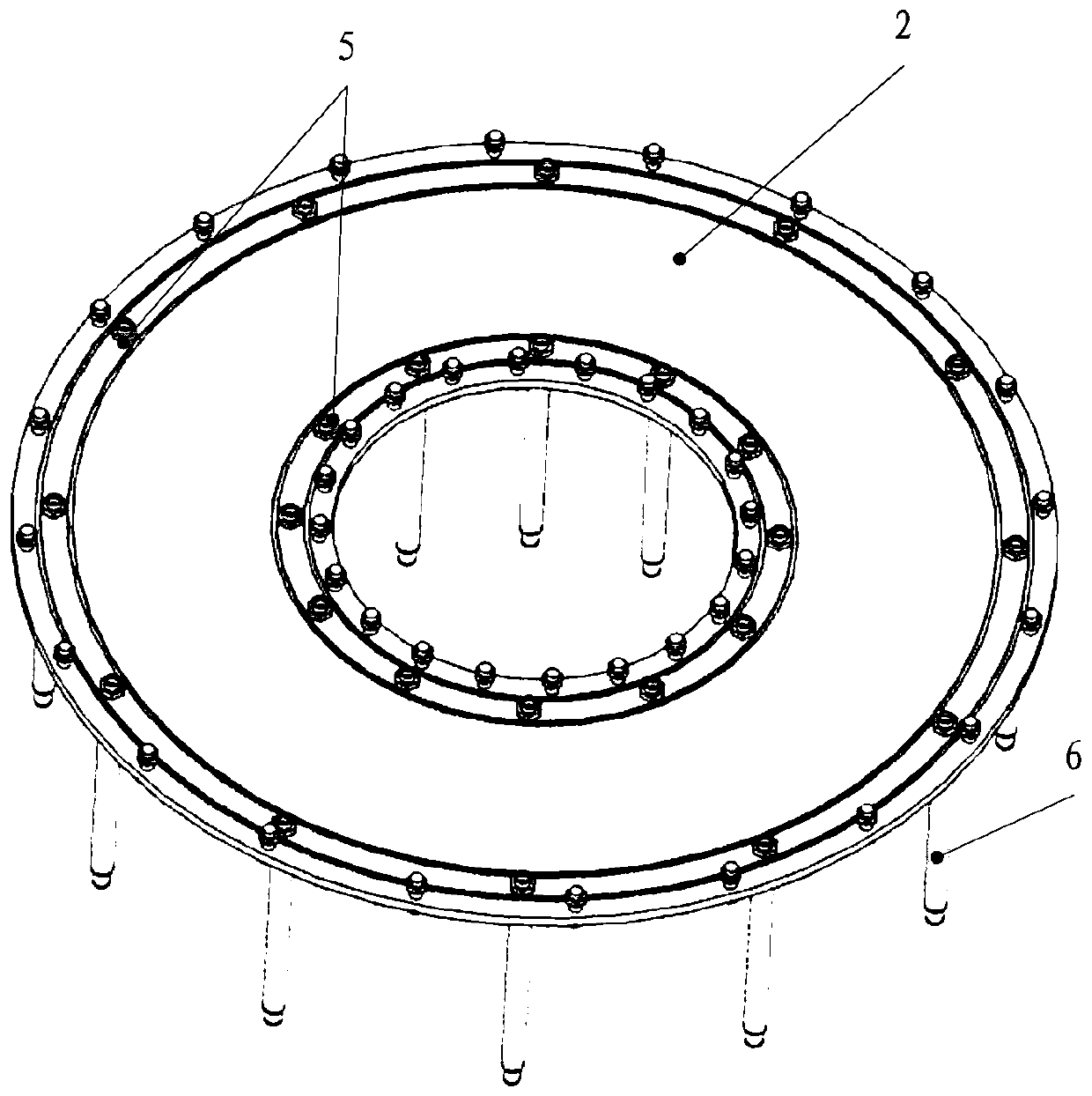

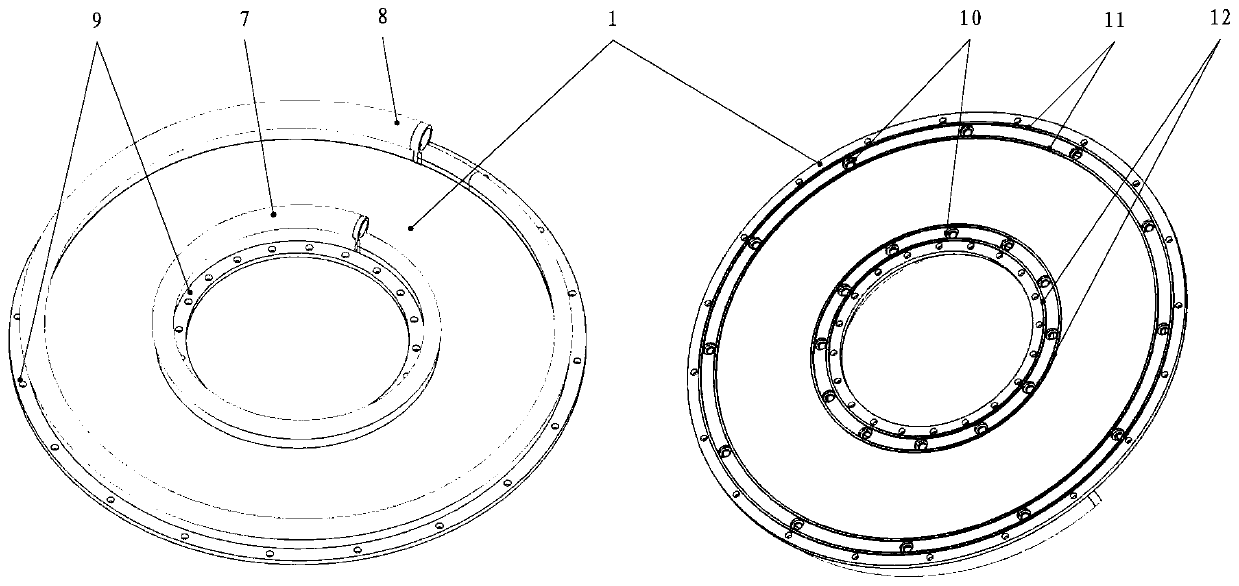

[0026] The present invention provides a diaphragm-type microtube precooler cooling working fluid gas collection device, which includes an integrated end cover 1, a support plate 2, a suture screw 3, a suture nut 4 and a lock nut 5;

[0027] One side of the integrated end cover 1 is provided with an annular gas collection pipeline 7 for the cooling medium to flow into the precooler and an annular gas collection pipeline 8 for the outflow of the precooler. The cross-sectional area of the annular gas collection pipeline 7 of the precooler gradually decreases along the flow direction, and the cross-sectional area of the annular gas collection pipeline 8 on the integrated end cover 1 for cooling working fluid to flow out of the precooler gradually decreases along the flow direction. Increased, the annular air collecting pipe 7 from which the cooling working...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com