Wear-resistant steel wire mesh pipe butt welding pipe fitting

A technology of butt welded pipe and steel wire mesh, which is applied in the direction of pipes/pipe joints/pipe fittings, pipeline connection arrangement, pipes, etc., can solve the problems of inability to maintain the consistency and separation of the steel wire mesh pipe system, and achieve the system material with, not easy to damage, improve The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment A wear-resistant steel wire mesh pipe butt welding pipe fitting

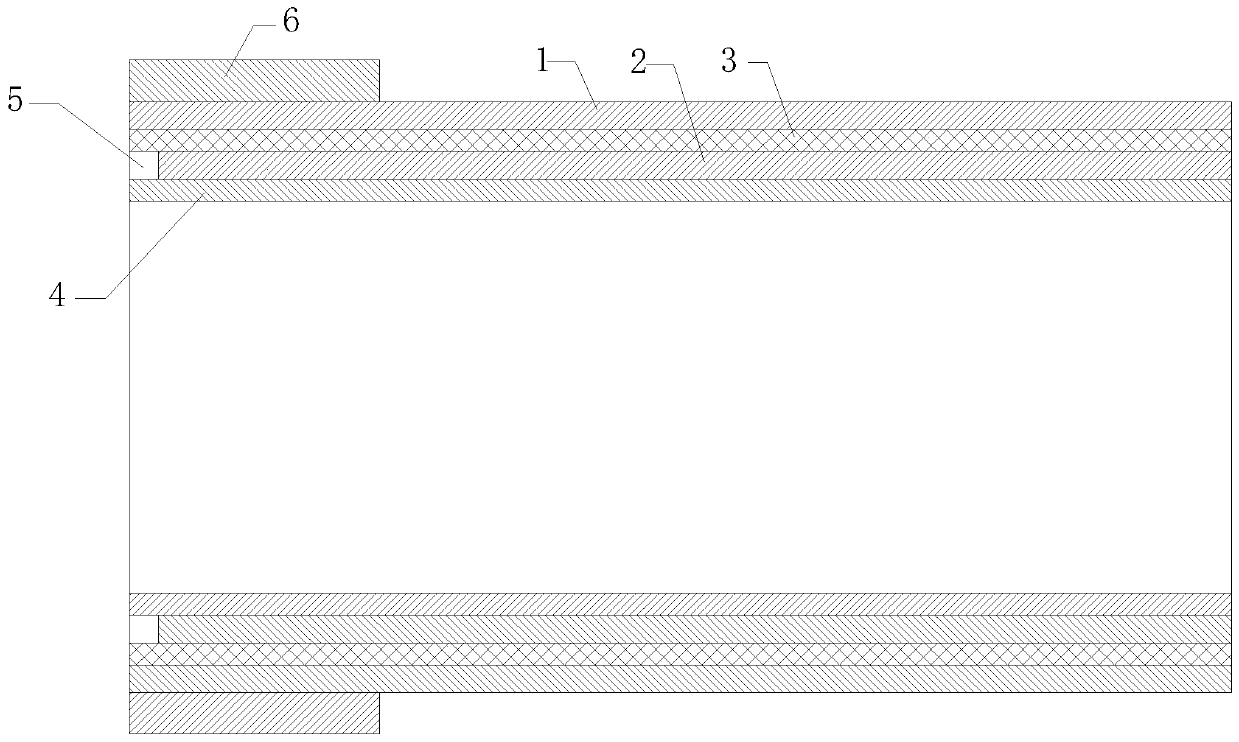

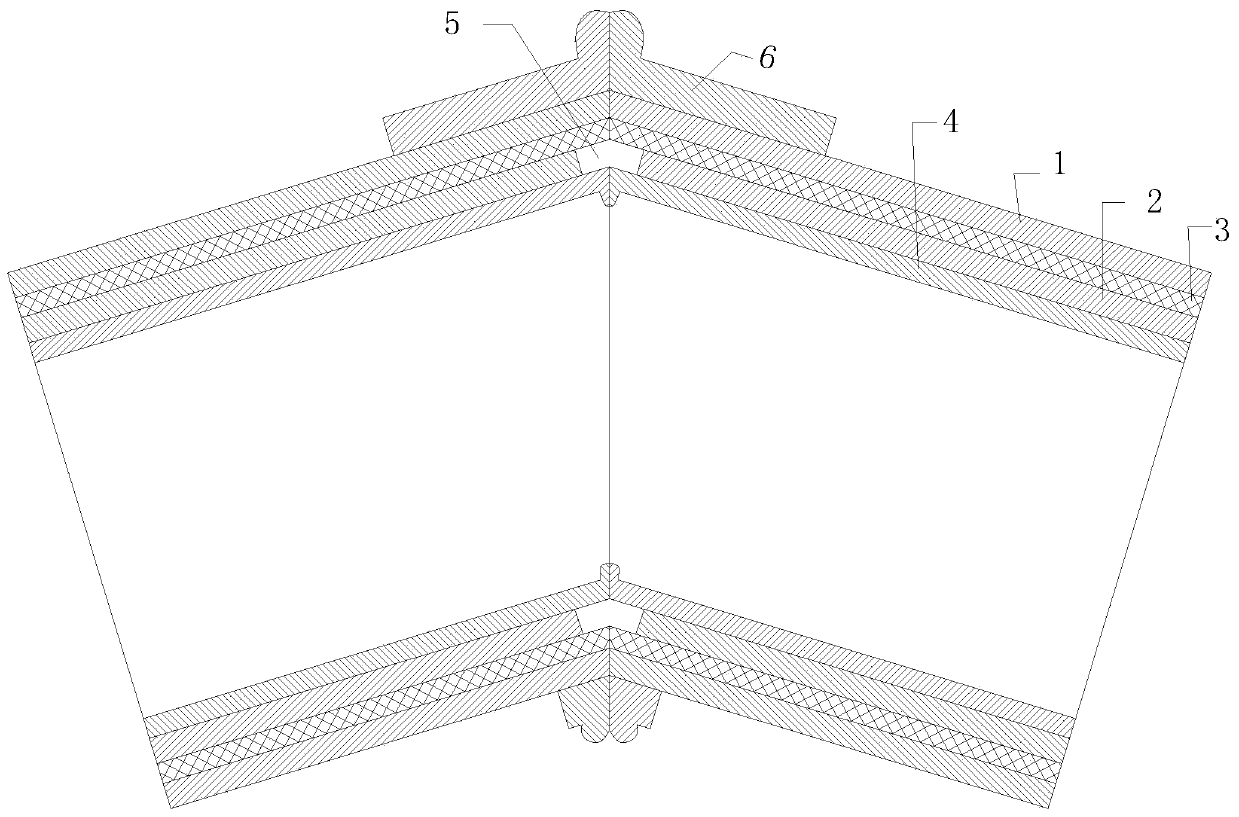

[0022] This embodiment discloses a wear-resistant steel wire mesh pipe butt welded pipe fitting, such as figure 1 with figure 2 As shown, it includes two short steel mesh pipes with inclined welding ends, and the two short steel mesh pipes are butt welded to each other. Pipeline grade polyethylene inner layer 2, pipeline grade polyethylene outer layer 1 and steel mesh reinforcement layer 3 sandwiched between them, steel mesh reinforcement layer 3 is composed of spirally wound steel wires as the skeleton, pipeline grade polyethylene inner layer The inner wall of the layer 2 is provided with a wear-resistant layer 4, the wear-resistant layer 4 is a weldable wear-resistant material, and the steel mesh reinforcement layer 3 is respectively bonded with the inner layer 2 of pipeline-grade polyethylene and the outer layer 1 of pipeline-grade polyethylene through bonding resin. Adhesion, the pipe gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com