Micro optical tweezer device and method based on self-focusing lens array

A self-focusing lens and focusing lens technology, applied in the field of optical manipulation, can solve the problems of inability to guarantee the capture force of optical tweezers, softness and easy deformation, poor repeatability of fiber optical tweezers, etc., to facilitate cell sorting and manipulation, ensure capture force, The effect of getting rid of space constraints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

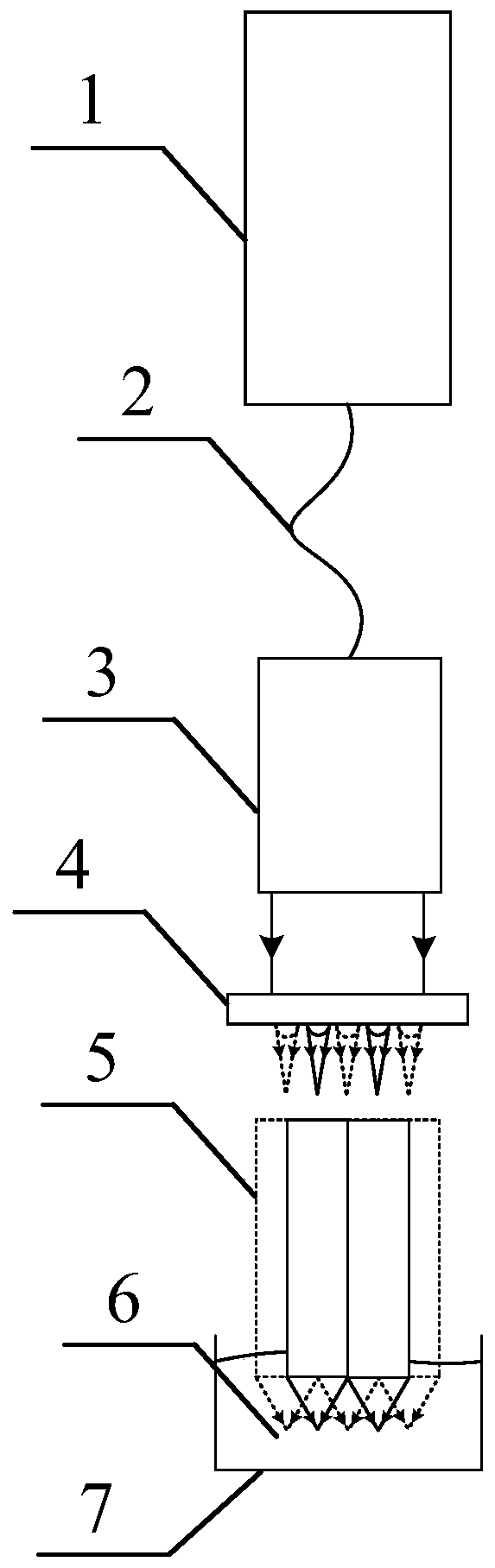

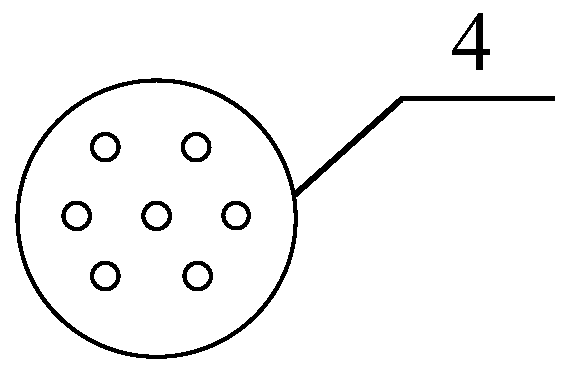

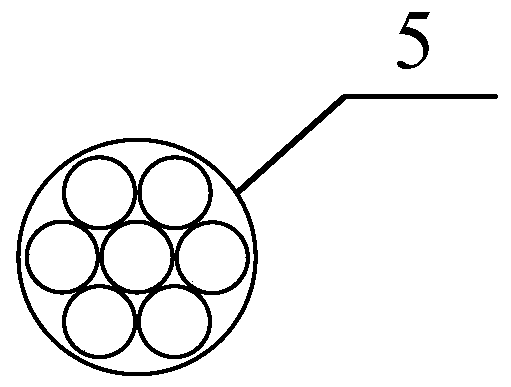

[0030] The structural diagram of the present invention is as figure 1 , a micro-optical tweezers device based on a self-focusing lens array, using 3D printing technology to build the core component of a personalized micro-optical tweezers device, using a high-numerical-aperture self-focusing lens array can produce a high-numerical-aperture tightly focused beam for integration in Cell sorting and manipulation in high-end microscopy imaging equipment. According to the direction of light propagation, they are: laser 1, optical fiber 2, collimator 3, microlens array 4, and self-focusing lens array 5, forming a focused beam and extending into the petri dish 7 to grab the sample 6; the sample 6 is placed on the petri dish 7 In the liquid environment, the liquid environment includes a culture medium.

[0031] In order to further optimize the above technical solution, the output fiber end of the laser is connected to a fiber coupler, and then connected to a collimator. The fiber coup...

Embodiment 2

[0039] A micro-optical tweezers implementation method based on a self-focusing lens array, comprising: a laser beam emitted by a laser 1 passes through an optical fiber 2 and a collimator 3 to form a parallel laser beam, and after the parallel laser beam enters a microlens array 4, N beams are focused Light, where N is greater than or equal to 3, the focused light is then coupled into the self-focusing lens array 5 to form a tightly focused beam of high numerical aperture, and the focused beam extends into the culture medium of the petri dish 7 to grab the sample 6 .

[0040] In order to further optimize the above technical solution, N beams of focused light are respectively incident on N high numerical aperture self-focusing lenses of the self-focusing lens array 5 .

[0041] In order to further optimize the above technical solution, the focused light is incident on the front working surface of the self-focusing lens array 5 at the focal plane of the microlens array 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com