Three-dimensional visual factory management system

A factory management, three-dimensional technology, applied in the field of three-dimensional visualization factory management system, can solve the problems of clearly understanding the production and working environment factors, and achieve the effect of reducing information communication barriers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

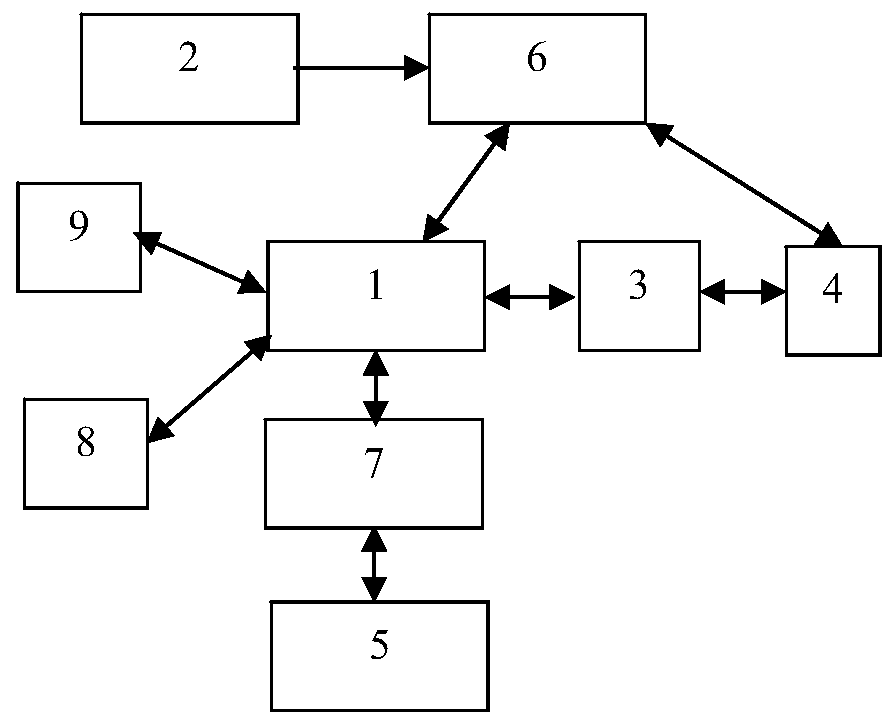

[0025] Such as figure 1As shown, the present invention provides a three-dimensional visualized factory management system, which at least includes a virtual simulation module 1 , a data acquisition module 2 , a data analysis module 3 and a decision management module 4 . The virtual simulation module 1 is used to carry out three-dimensional virtual simulation of the production elements in the factory, and then realize the digital transformation of the production elements from the physical state to the 3D virtual state to obtain a three-dimensional virtual factory. For example, the virtual simulation module 1 can construct a three-dimensional virtual simulation model of production factors in a panoramic scanning manner. The data collection module 2 is used to collect the production data involved in the production factors. Taking a factory as an example, the factors of production include at least all the buildings in the factory, the production equipment placed in the buildings, ...

Embodiment 2

[0045] This embodiment is a further improvement on Embodiment 1, and repeated content will not be repeated here.

[0046] Such as figure 1 As shown, the 3D visualized factory management system also includes a data interface 5 , a 3D visualization module and a human-computer interaction module 7 . The data interface 5 can perform two-way communication with other factory management systems, and then can acquire various production data, and transmit the collected production data to the data acquisition module 2 . Other factory management systems include, but are not limited to, ERP systems, MES systems, E-HR systems, CPC systems, EAM systems, PLS systems, SRM systems, PLM systems, and QMS systems. For example, it can communicate with the EAM system through the data interface 5, and then can query the historical work order data of the factory and create and initiate work order data. Or communicate with the equipment management system, and then you can query the spare parts data ...

Embodiment 3

[0048] This embodiment is a further improvement on the foregoing embodiments, and repeated content will not be repeated here.

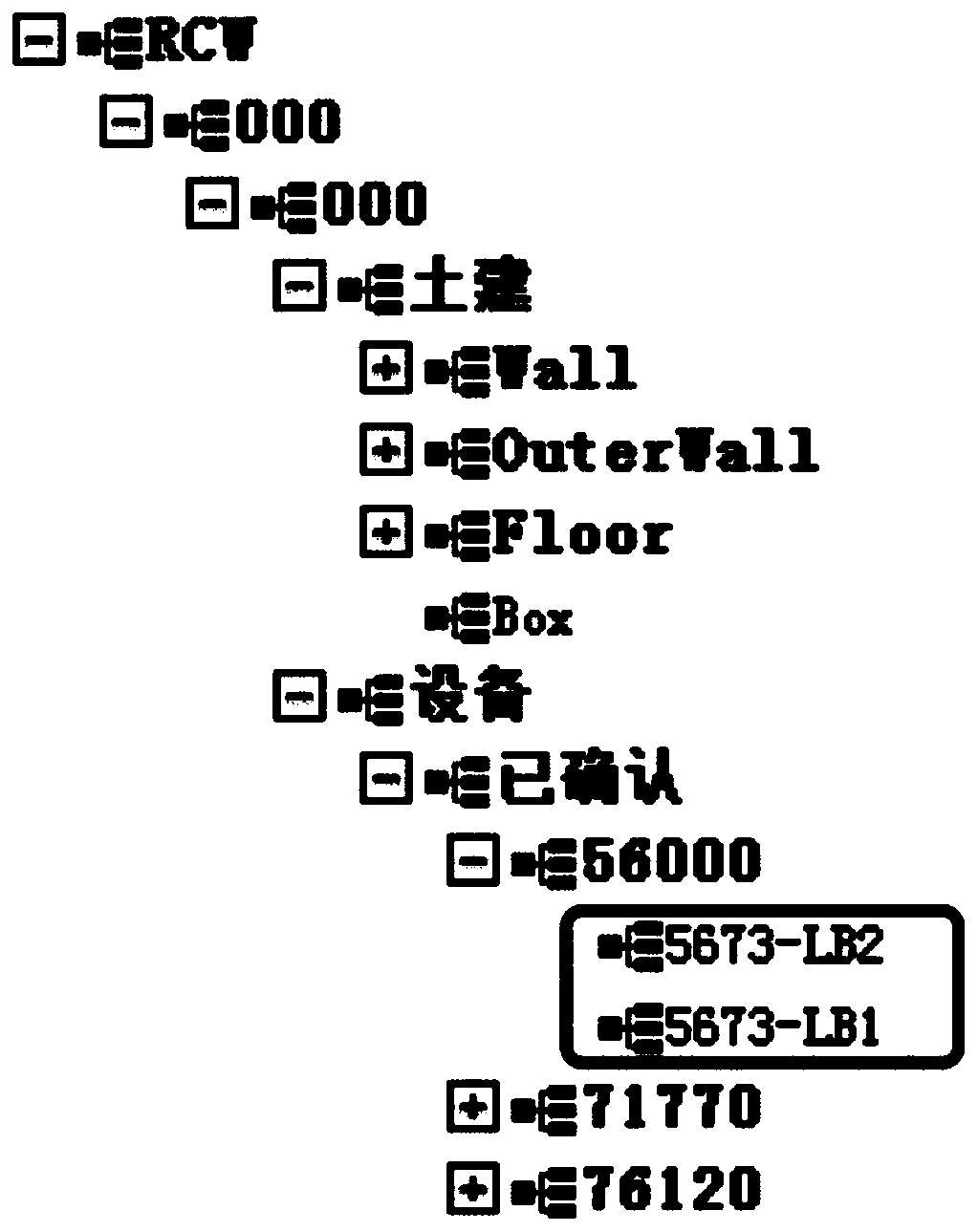

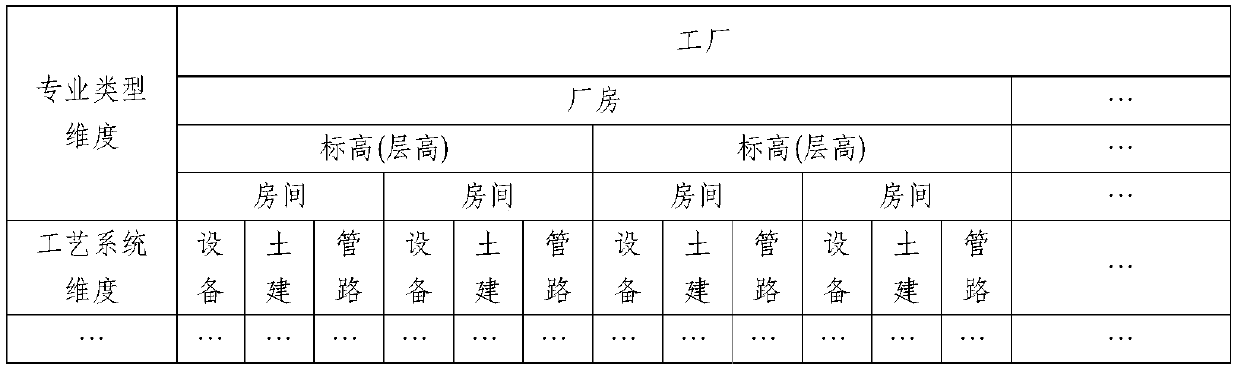

[0049] Preferably, in the physical physical environment of the factory, both the production elements and the environment elements can be configured with at least one of the first setting code, the second setting code and the third setting code that can be visually displayed. Specifically, several factories can be arranged in one park. For example, for car companies, different models are often configured in different factories for manufacturing. In the actual physical environment, in order to distinguish different factories, it is necessary to use factories with different names such as A factory, B factory, and C factory. distinguish. "A factory, B factory, C factory" and so on are natural languages that people can directly understand their meanings. In the present invention, natural languages such as factory A, factory B, and factory C can be co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com