Three-electrode battery and preparation method thereof

A three-electrode and battery technology, applied in the field of lithium-ion batteries, can solve problems such as damage to charged batteries, three-electrode failure, impact analysis, etc., to reduce errors, make up for analysis and detection vacancies, and improve efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] A method for preparing a three-electrode battery, comprising the steps of:

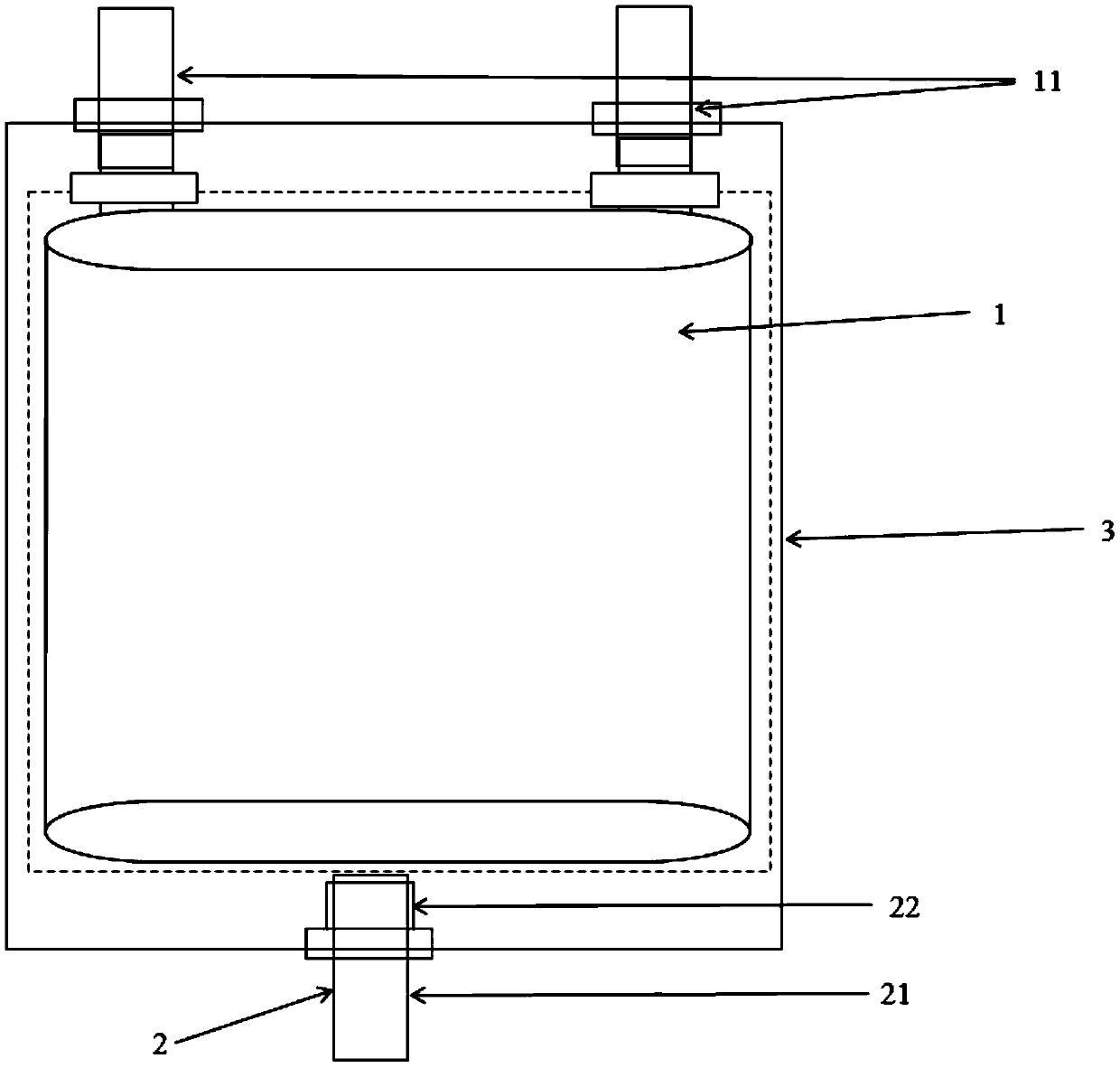

[0037] S1, connecting the first tab 11 to the positive and negative tabs of the charged cell body 1 respectively, wherein the first tab 11 is partly exposed outside the battery case 3;

[0038] S2, coating the diaphragm 22 on the reference electrode 2 and connecting the second tab 21, the second tab 21 is partially exposed outside the battery case 3, and the second tab 21 is welded to the reference electrode 2 or connected to the reference electrode 2 is integrally formed, the diaphragm 22 is set in the battery case 3, and the reference electrode 2 is kept out of contact with the charged cell body 1;

[0039] S3, first insulate the metal part outside the primary battery shell of the charged cell body, and use insulating tape to avoid short circuit of the charged cell during top sealing; then top seal the three-electrode battery, among which, the top seal The packaging temperature is 160-200°C,...

Embodiment 1

[0044] A method for preparing a three-electrode battery, comprising the steps of:

[0045] S1, solder the black glue tabs to the positive and negative tabs of the charged battery body 1, so that it has the ability to repackage;

[0046] S2, cut a lithium sheet with a certain width, the second tab 21 is also a vinyl tab, wind the lithium sheet around one end of the vinyl tab and press it tightly to make the two tightly combined, which is equivalent to the second tab 21 and the participating The specific electrode 2 is integrally formed with a lithium strip, and then a layer of separator 22 is wrapped around the lithium sheet with a stop glue. Both the separator 22 and the lithium sheet are set in the aluminum-plastic film, but attention should be paid to the stop glue not being close to the end to prevent it from blocking the electrolyte. The black glue tab part is exposed outside the aluminum-plastic film;

[0047] S3, cutting a new aluminum-plastic film (that is, the battery...

PUM

| Property | Measurement | Unit |

|---|---|---|

| internal resistance | aaaaa | aaaaa |

| internal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com