Bird nest cleaner based on insulating operating rod

A technology of insulating operating rods and cleaners, which is applied in the field of bird's nest cleaners, can solve the problems of difficult operation, labor-consuming, inconvenient use, etc., and achieve the effect of small occupied space and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

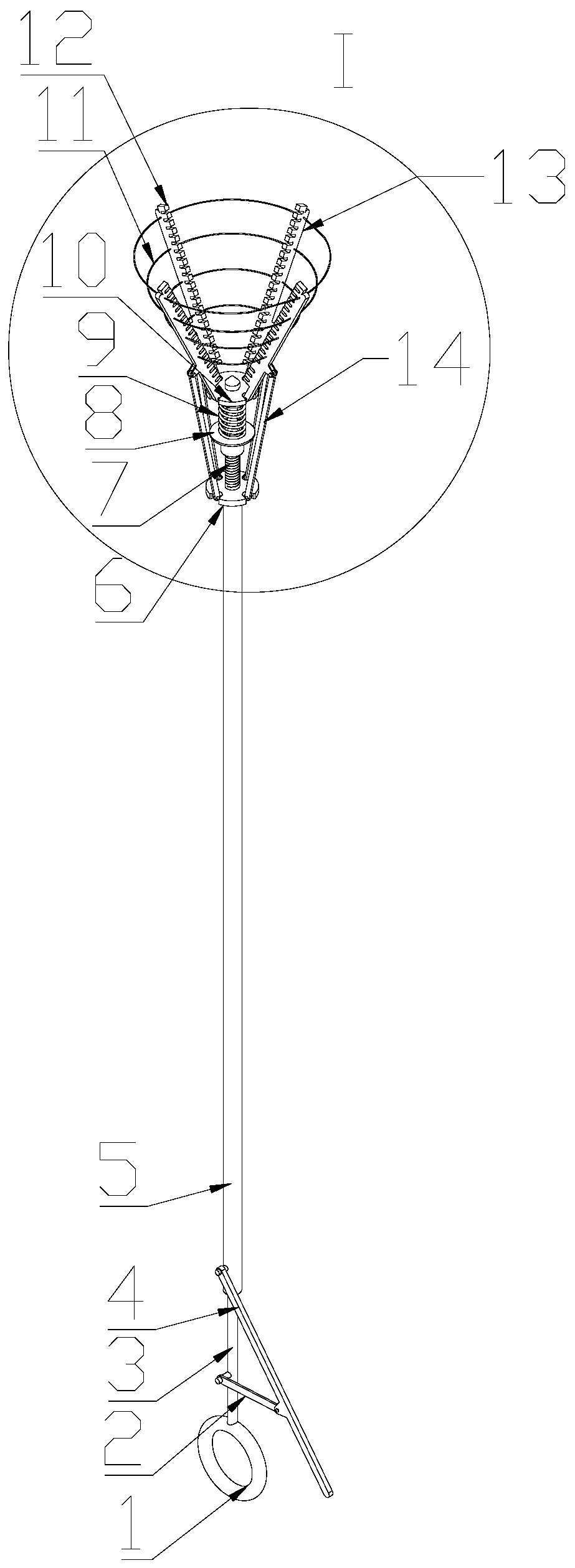

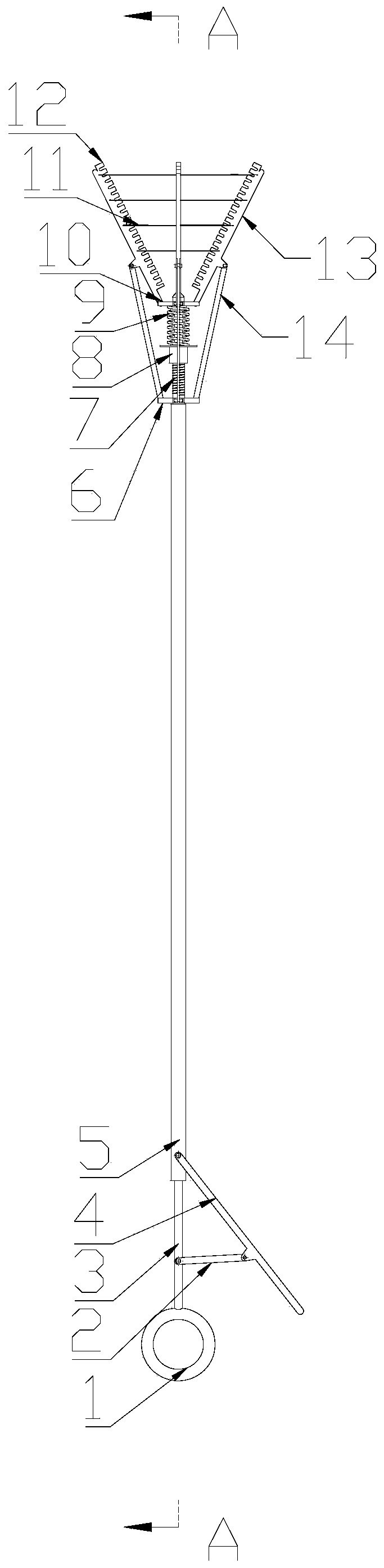

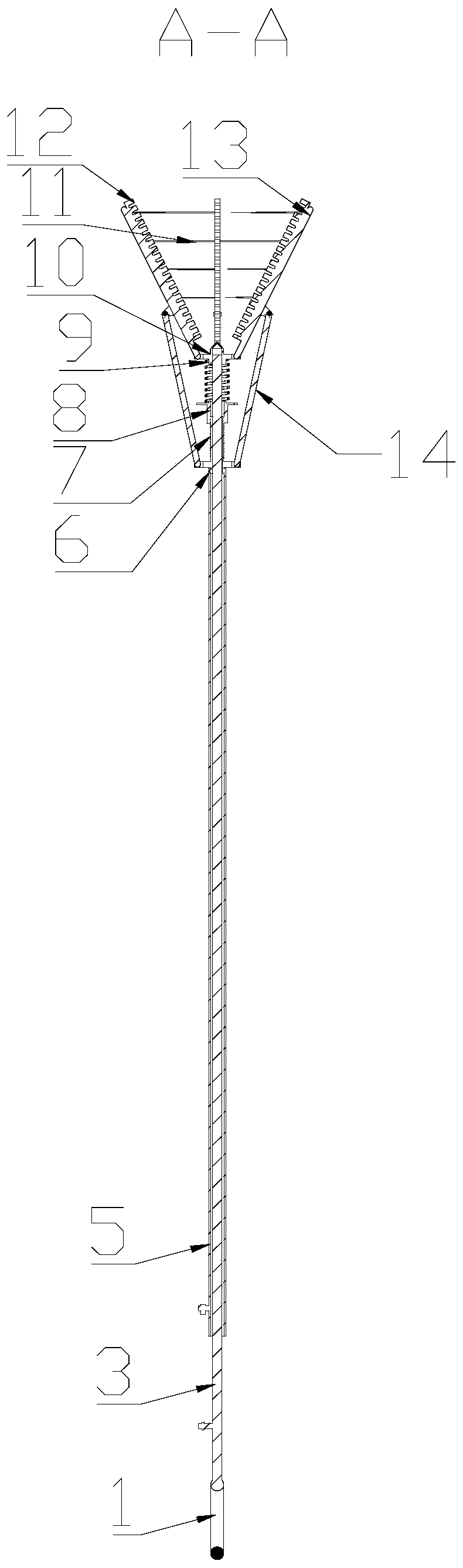

[0028] In order to solve the problem that the existing bird’s nest cleaner is inconvenient to use in the narrow and small high-voltage electric towers, and the manual lifting of the bird’s nest cleaning equipment while applying clamping force consumes a lot of physical strength, the present invention proposes a bird’s nest cleaner based on an insulating operating rod, including an outer There is an inner support tube 3 inside the cavity of the support tube 5, and there is a gap between the two. The top of the outer support tube 5 is threadedly connected with the slider 6, and a threaded tube 7 is fixedly connected to the upper end of the slider 6, and the two are fixed as one. , the connecting piece 8 is threadedly connected with the threaded pipe 7, and the connecting piece 8 on the inner support pipe 3 can be rotated to adjust the height position of the connecting piece 8 on the threaded pipe 7, thereby adjusting the maximum opening between the insulating splint 13 and the ver...

Embodiment 2

[0035] Such as Figure 5 As shown, another embodiment of the bird's nest cleaner of the present invention is provided. Compared with Embodiment 1, the insulating splint 13 of this embodiment is not equipped with an elastic band 11, and the elastic force of the spring 9 is used to push the slider 6 along the inner support tube. 3. The outer contour moves downward, so that the upper link 14 pulls the insulating splint 13 to shrink towards the center, and the elastic force produced by the spring 9 is used to clamp the branches, straw, etc. on the bird's nest, which saves manpower and is easy to use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com