Mahjong machine and tile feeding mechanism thereof

A technology for mahjong tiles and card delivery, which is applied to the field of mahjong machines and their card delivery mechanisms, can solve the problems of low space utilization rate of the main frame, complicated assembly process, inability to effectively combine card stacking components and card pushing components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

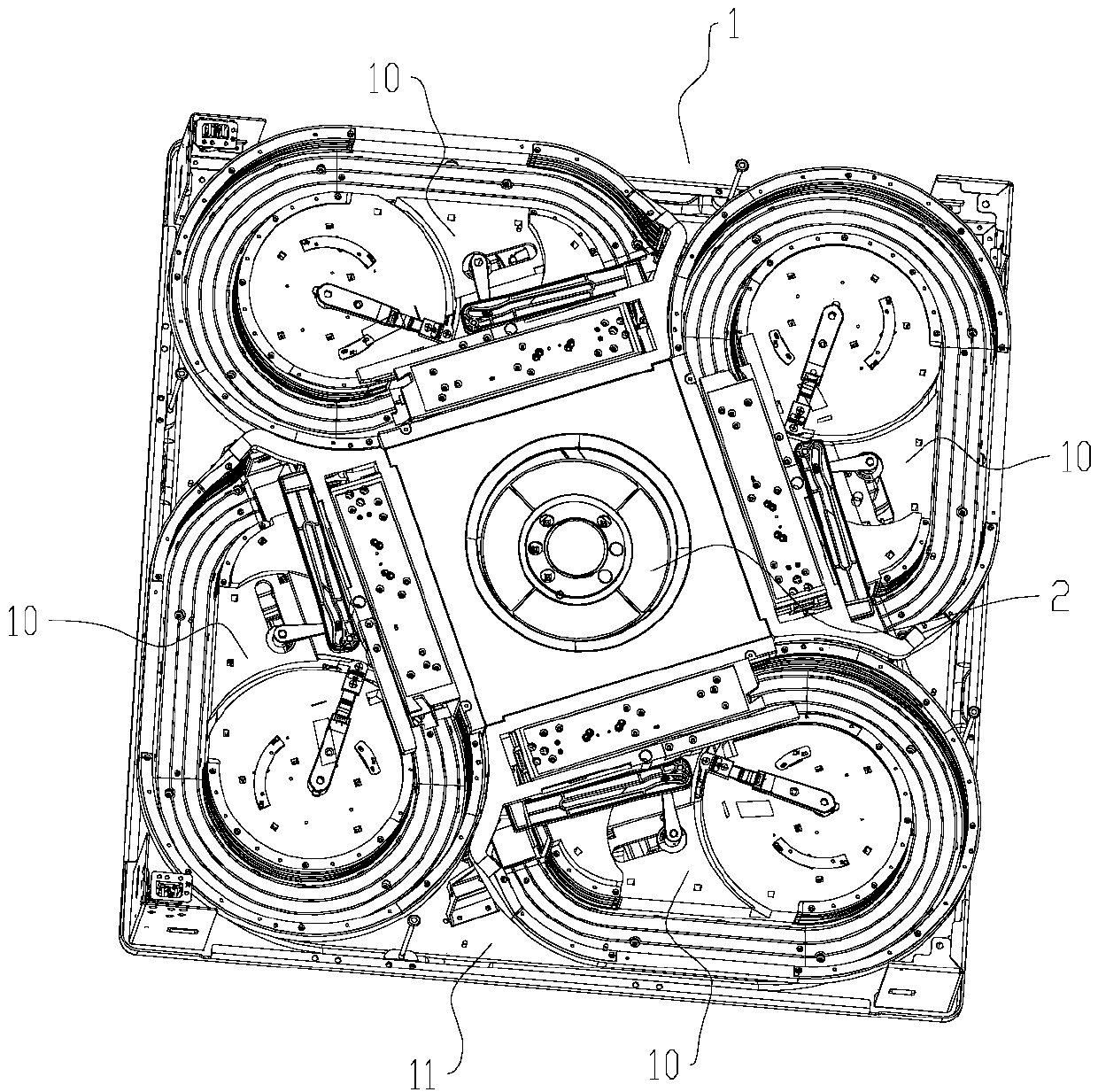

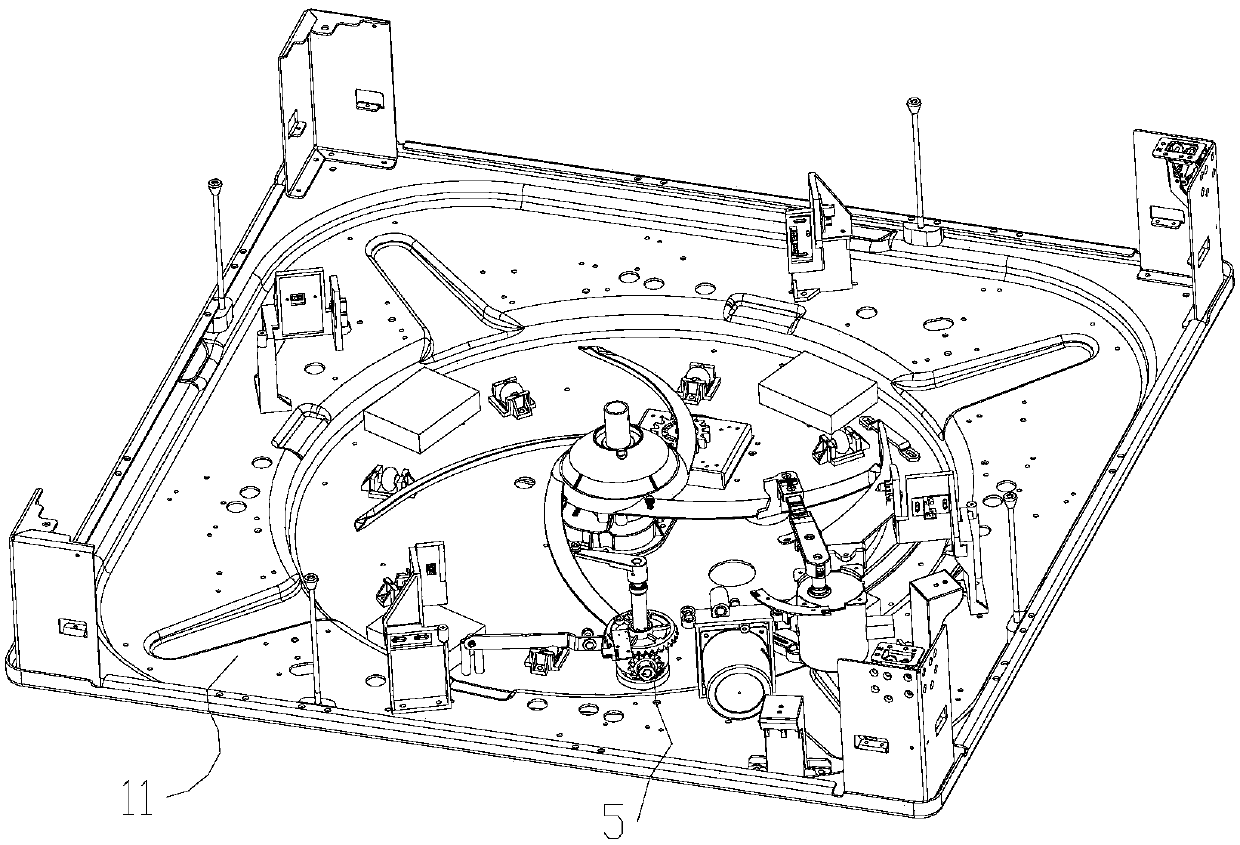

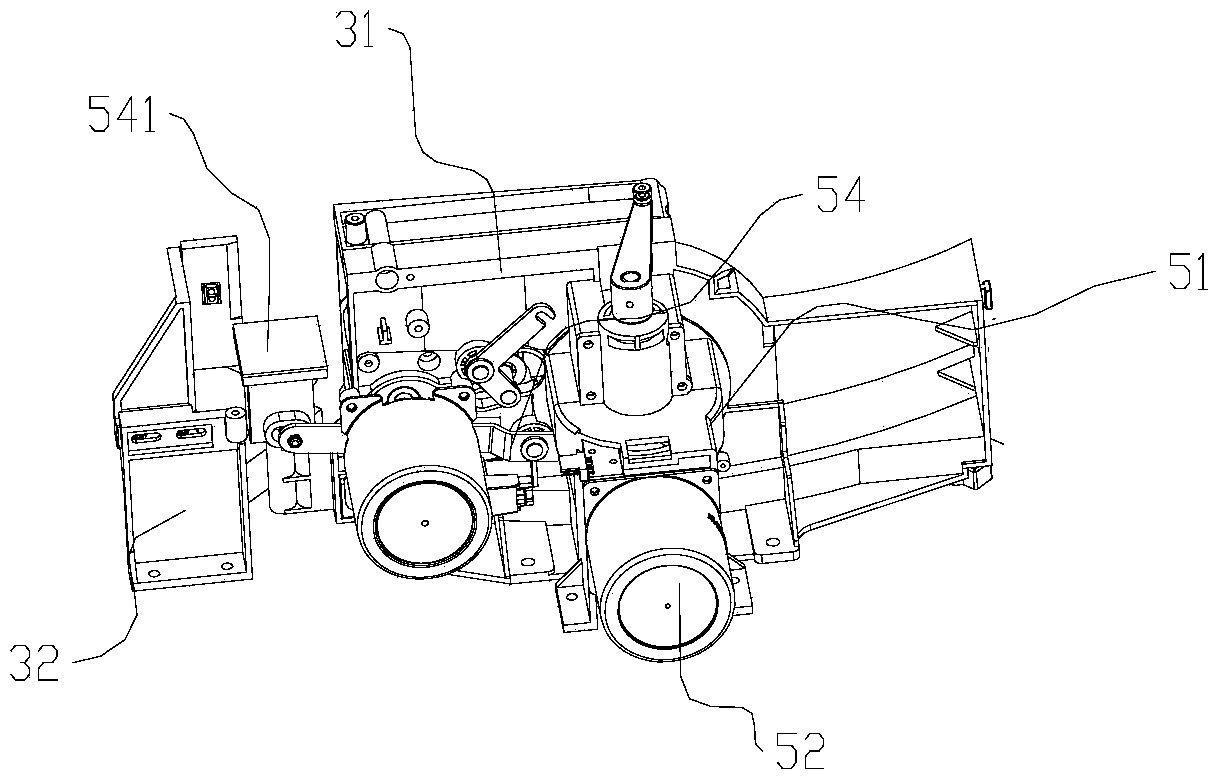

[0052] Such as Figure 1-12 A kind of automatic mahjong machine shown, comprises frame, and the main base 1 that is arranged on the frame, and the central control board assembly 2 that is arranged in main base 1, shuffling plate, and the surrounding that is arranged around the shuffling plate Four groups of pick-up card handling systems 10. Wherein, the main base 1 includes a bottom plate 11, a desktop board, and a frame connecting the edge of the bottom plate 11 and the edge of the desktop board; The group pick-up card handling system is respectively located on the four sides of the shuffling tray and arranged around the shuffling tray. The center position of the desktop board is provided with a card inlet, the card inlet is located above the center of the main machine cavity, the lower end of the central control panel assembly 2 is connected in the main machine cavity, and the lifting and lowering movement relative to the desktop board is realized through the lifting struct...

Embodiment 2

[0067] This embodiment relates to a method for arranging tiles of an automatic mahjong machine. The method for arranging tiles adopts the structure of the automatic mahjong machine as described in Embodiment 1. The card sorting method is suitable for four-socket mahjong machines, see the attached Figures 13 to 17 , specifically, includes the following steps:

[0068] 1) Shuffling: the movement of the shuffling plate, the mahjong tiles entering the shuffling plate move with the shuffling plate, and the order of the mahjong tiles is disrupted;

[0069] 2) Pick up cards and send cards; pick up the mahjong tiles on the shuffling tray and send them out; specifically, the mahjong tiles on the shuffling tray are sent to the bottom of the inlet ends of the four card delivery mechanisms 3 on the edge of the shuffling tray, and the mahjong tiles are removed. The suction card wheel in the card delivery mechanism 3 is sucked up and straightened out to be sent into the card delivery chan...

Embodiment 3

[0075] This embodiment relates to a method for arranging tiles of an automatic mahjong machine. The method for arranging tiles adopts the structure of the automatic mahjong machine as described in Embodiment 1. The card sorting method is adapted to the eight-socket mahjong machine, see the attached Figures 18-25 , specifically, includes the following steps:

[0076] 1) Shuffling: the movement of the shuffling plate, the mahjong tiles entering the shuffling plate move with the shuffling plate, and the order of the mahjong tiles is disrupted;

[0077] 2) Pick up and send cards; pick up the mahjong tiles on the shuffling tray and send them out; the mahjong tiles on the shuffling tray are sent to the bottom of the inlet ends of the four card delivery mechanisms 3 on the edge of the shuffling tray, and the mahjong tiles are delivered The suction wheel in the mechanism 3 is sucked up and sorted out into the same direction and sent into the card delivery channel, and the mahjong ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com