Spray drying device and method for preparing nano material

A nanomaterial and drying device technology, applied in spray evaporation, evaporator accessories, etc., can solve the problems of poor drying effect, excessive heat of exhaust gas, and limited dispersion effect, and achieve the effect of ensuring drying effect and improving the degree of dispersion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

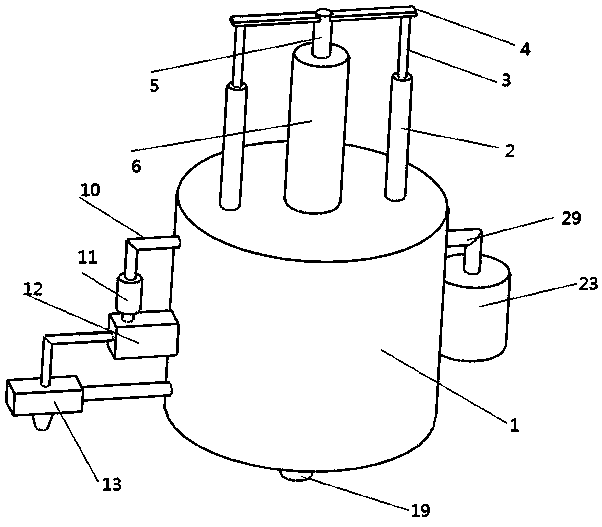

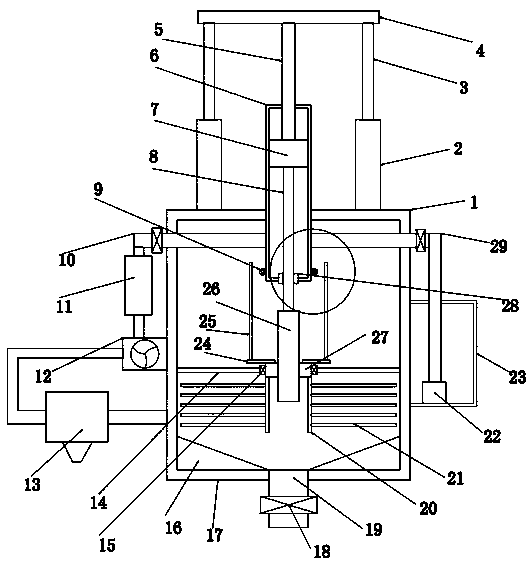

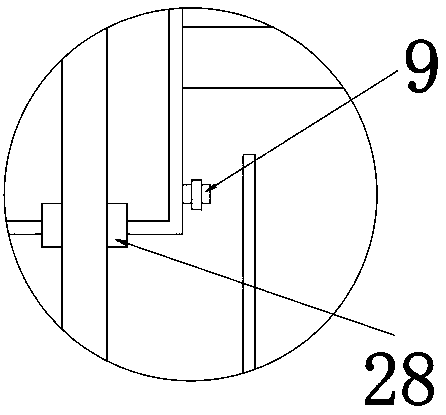

[0029] see Figure 1-3 , in an embodiment of the present invention, a spray drying device for preparing nanomaterials, comprising a reaction box 1 and a discharge pipe 19 arranged at the lower end of the reaction box 1, the discharge pipe 19 is provided with a discharge valve 18, and the discharge pipe 19 is provided with a discharge valve 18. The inner bottom of the reaction box 1 where the pipe 19 is located is provided with a material guide cone 16 to facilitate the collection of materials, the surface of the reaction box 1 is provided with a heat insulating layer 17, and the middle position of the upper end of the reaction box 1 is pierced with a mixing cylinder 6 , the air intake end on the lower left side of the mixing cylinder 6 is connected to an air intake component, and the feed end on the lower right side of the mixing cylinder 6 is connected to a feeding component;

[0030] An extruding piston block 7 is slidably fitted inside the mixing cylinder 6, the upper end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com