Automatic cleaning mechanism for photovoltaic power generation panel

A technology of automatic cleaning and photovoltaic power generation, applied in photovoltaic power generation, cleaning methods using tools, cleaning methods using liquids, etc., can solve the problems of lack of renewable energy, heavy workload, low cleaning efficiency, etc., to achieve long-term benefits Long-term use, improved service life, and improved lubricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

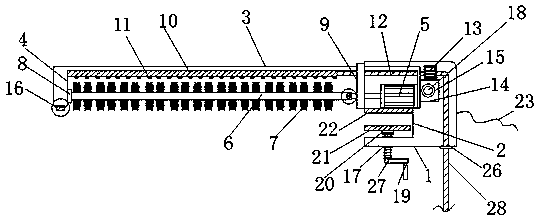

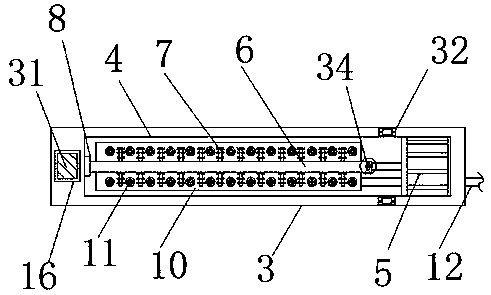

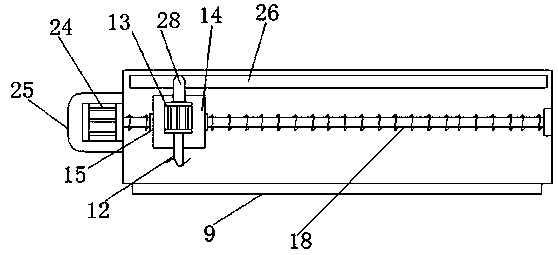

[0029] refer to Figure 1-5 , an automatic cleaning mechanism for photovoltaic power generation panels, including a casing 1, a dust removal cover 3, an infusion plate 10, an atomizing head 11, and a photovoltaic panel 30; the left side of the casing 1 is provided with a chute 9 and a clamping groove 2, and the chute 9 is located at the upper end of the clamping groove 2, the chute 9 has a built-in dust removal cover 3, and the bottom end of the dust removal cover 3 is provided with a cleaning groove 4, and the right end of the cleaning groove 4 is provided with a first motor 5, And the end of the motor shaft of the first motor 5 is provided with a rotating rod 6, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com