Technical method for carrying out extrusion forming on local additive manufacturing pre-formed aluminium alloy

An additive manufacturing and extrusion forming technology, applied in the field of precision forming and processing, can solve the problems that the manufacturing technology cannot meet the high-end manufacturing field, overweight internal quality, inability to achieve high efficiency, etc. The effect of cycle shortening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

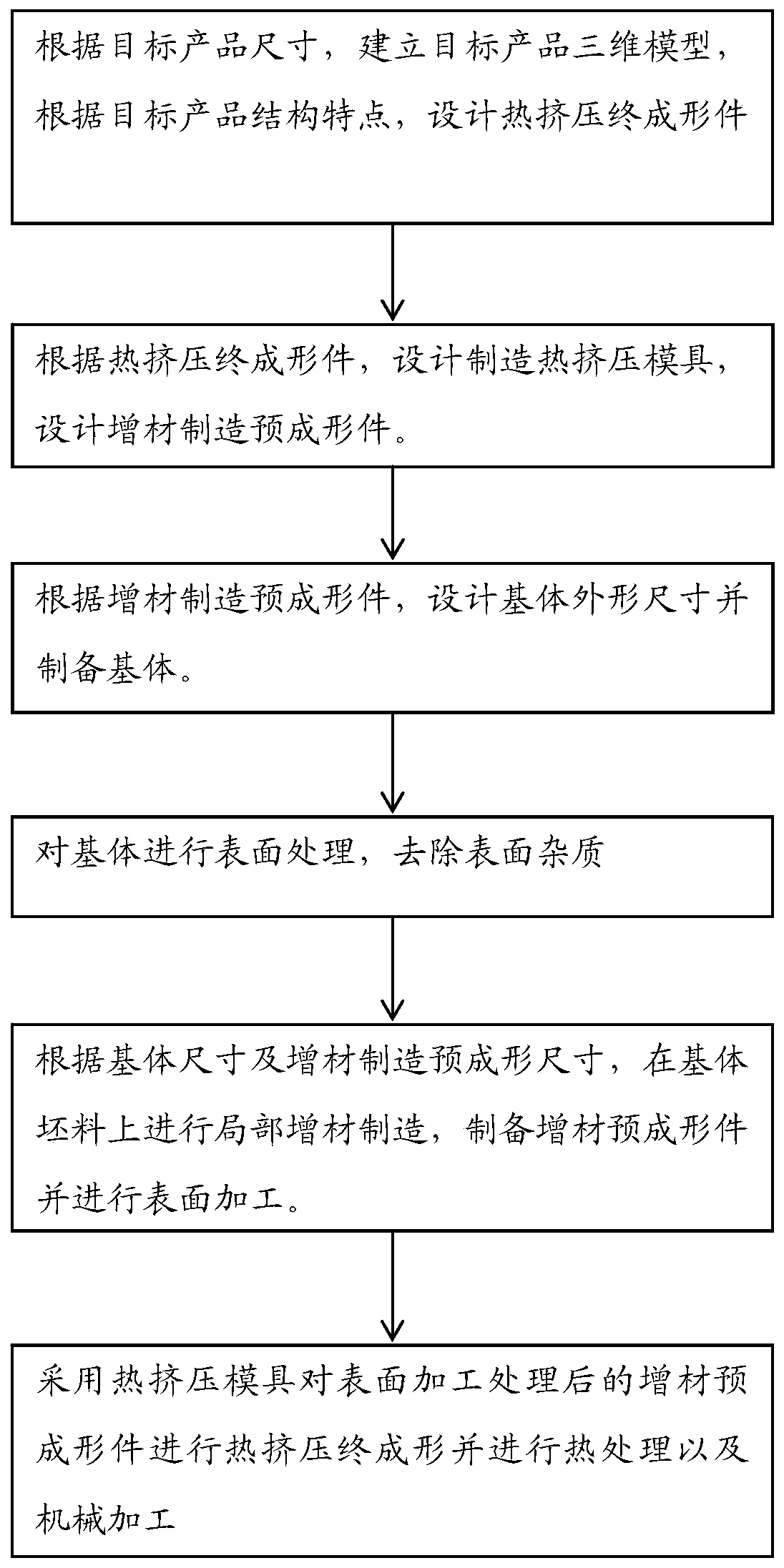

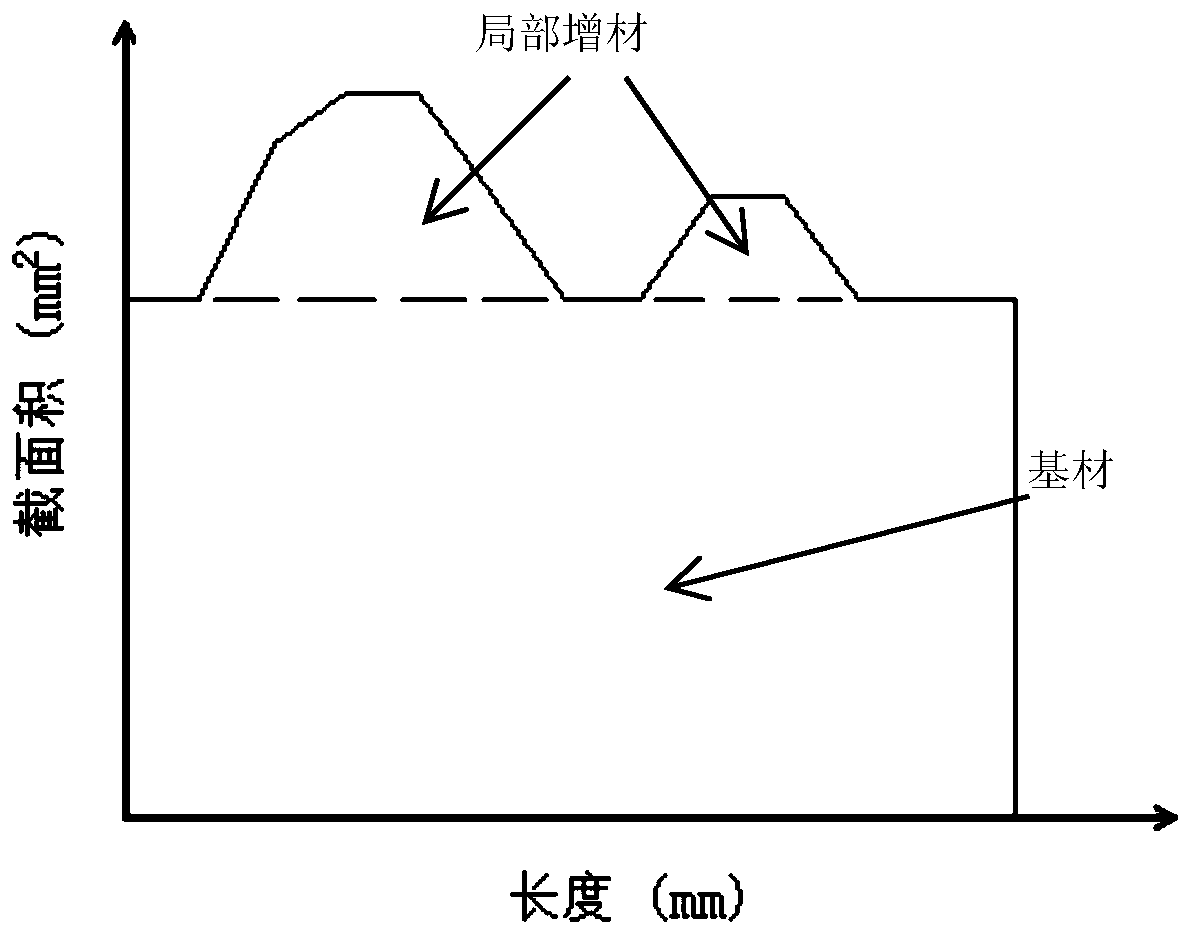

Method used

Image

Examples

Embodiment 1

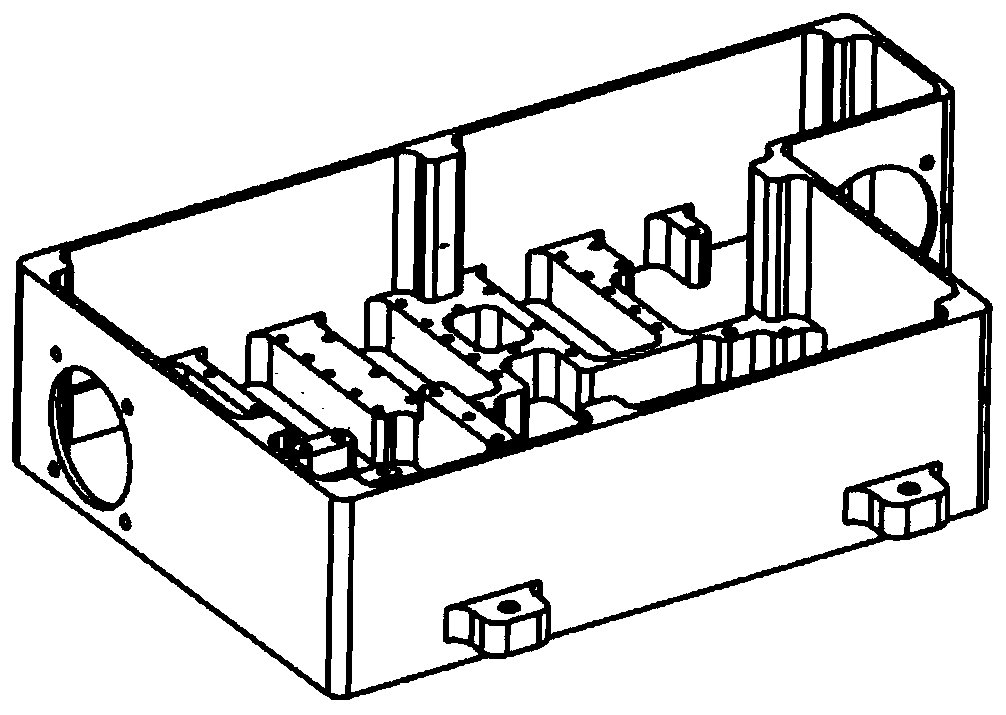

[0086] Taking a 5A06 aluminum alloy multi-boss deep cavity box as an example, it is manufactured as follows:

[0087] 1. Draw a two-dimensional dimension sketch through points, straight lines, arcs, etc. Secondly, the sketch is constructed by stretching, and then different parts of the body are constructed by Boolean operations to construct local boss dimension features, and finally, such as chamfering and chamfering Design and construct target box-shaped parts such as circles, whose maximum three-dimensional dimension is (350*260*70) mm, such as image 3 shown.

[0088] 2. According to the three-dimensional model of the box-shaped piece, one end of the bottom surface of the box-shaped piece is used as the parting surface, and the bottom surface is at the size T of the box-shaped piece. f0 Based on the design process margin t 0 , where t 0 =3mm, the size of the parting surface of the hot extrusion final part is T f1 =T f0 +t 0 , at the same time from the parting surface ...

Embodiment 2

[0100] Taking a 2A12 aluminum alloy variable diameter rotary shaft as an example, it is manufactured as follows:

[0101] 1. Draw a two-dimensional dimension sketch through points, straight lines, etc. Secondly, the sketch is constructed by rotating the body, and then different parts of the body are constructed by Boolean operations to construct local dimension features, and finally, chamfering is performed to construct the final target rotary shaft. The maximum three-dimensional dimension is (Φ75*310) mm, such as Figure 8 shown.

[0102] 2. According to the three-dimensional model of the rotary shaft, the part has the characteristics of axisymmetric structure. Therefore, the surface passing through the axis is the parting surface, and the diameter of different parts at the parting surface is T f1 =T f0 +t 0 , at the same time from the parting surface to each section at the end T x1 =T x0 +t x , the final dimensions of the hot extrusion parts are (Φ85*320)mm~(Φ40*320)mm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com