Movable air bag type lifting belt sander and operation method thereof

A belt machine and air bag technology, which is applied in the direction of belt grinder, grinding machine, grinding/polishing equipment, etc., can solve the problem of occupying crane resources and achieve the effects of reducing labor intensity, increasing mobility, and convenient adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

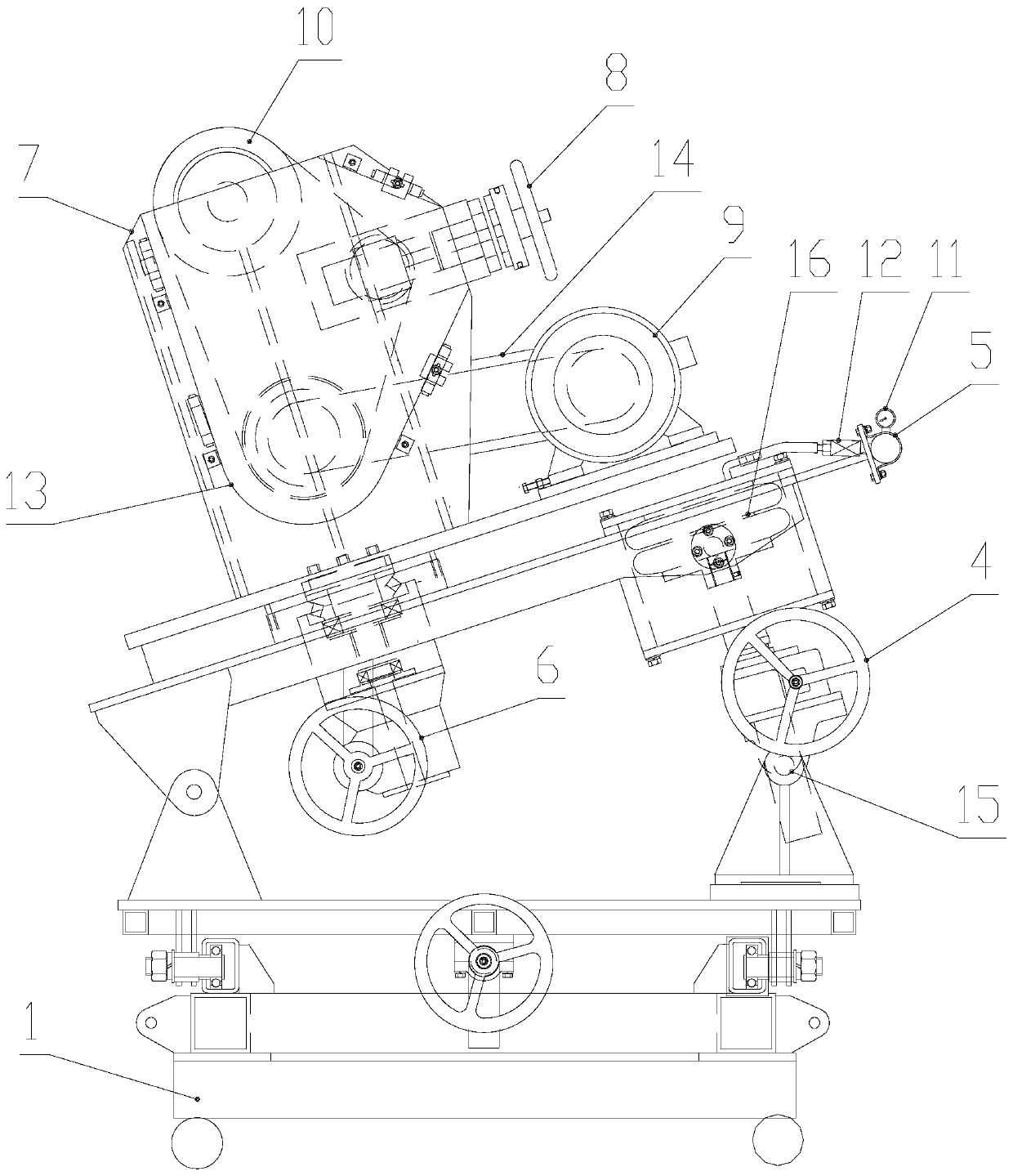

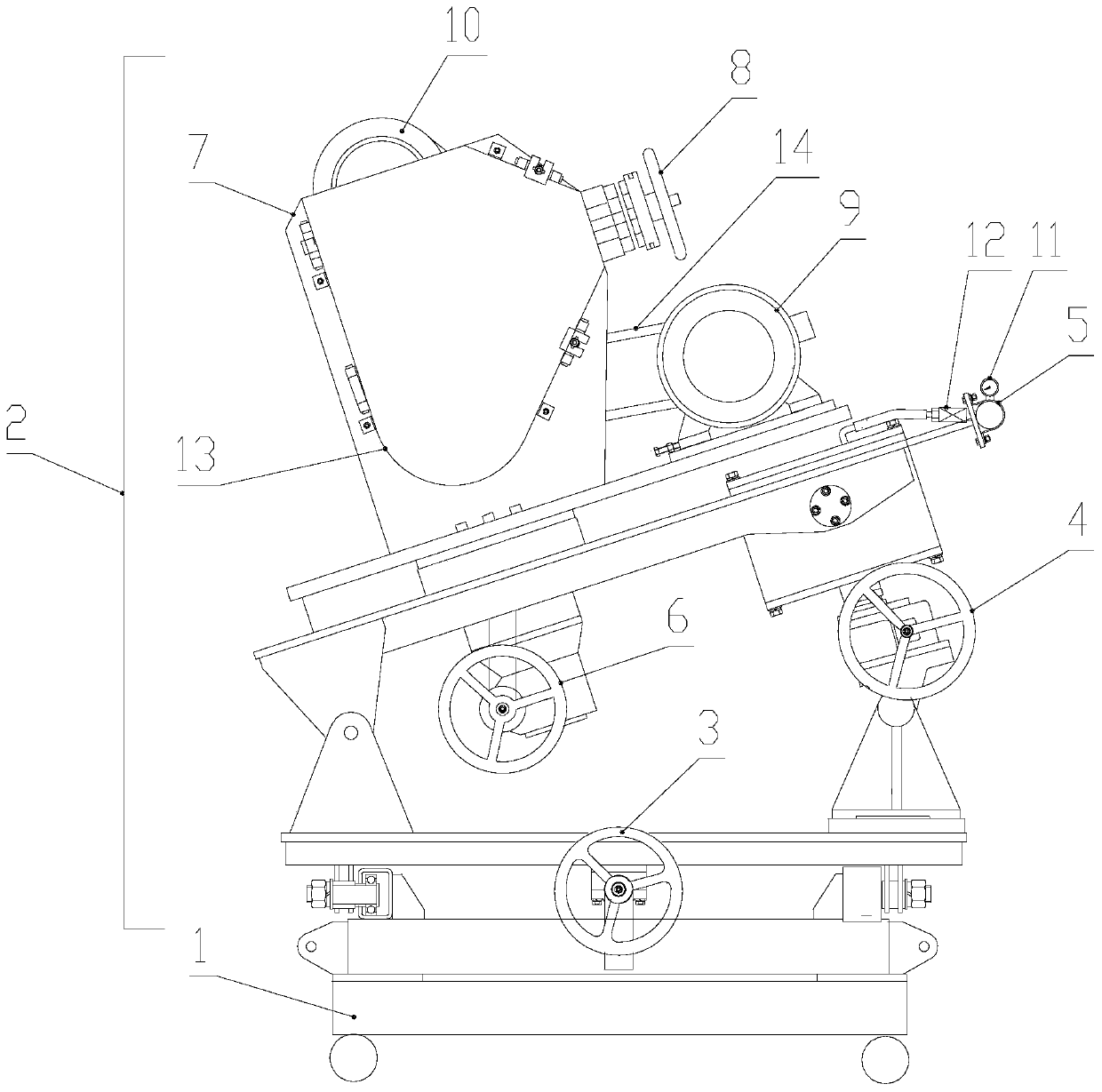

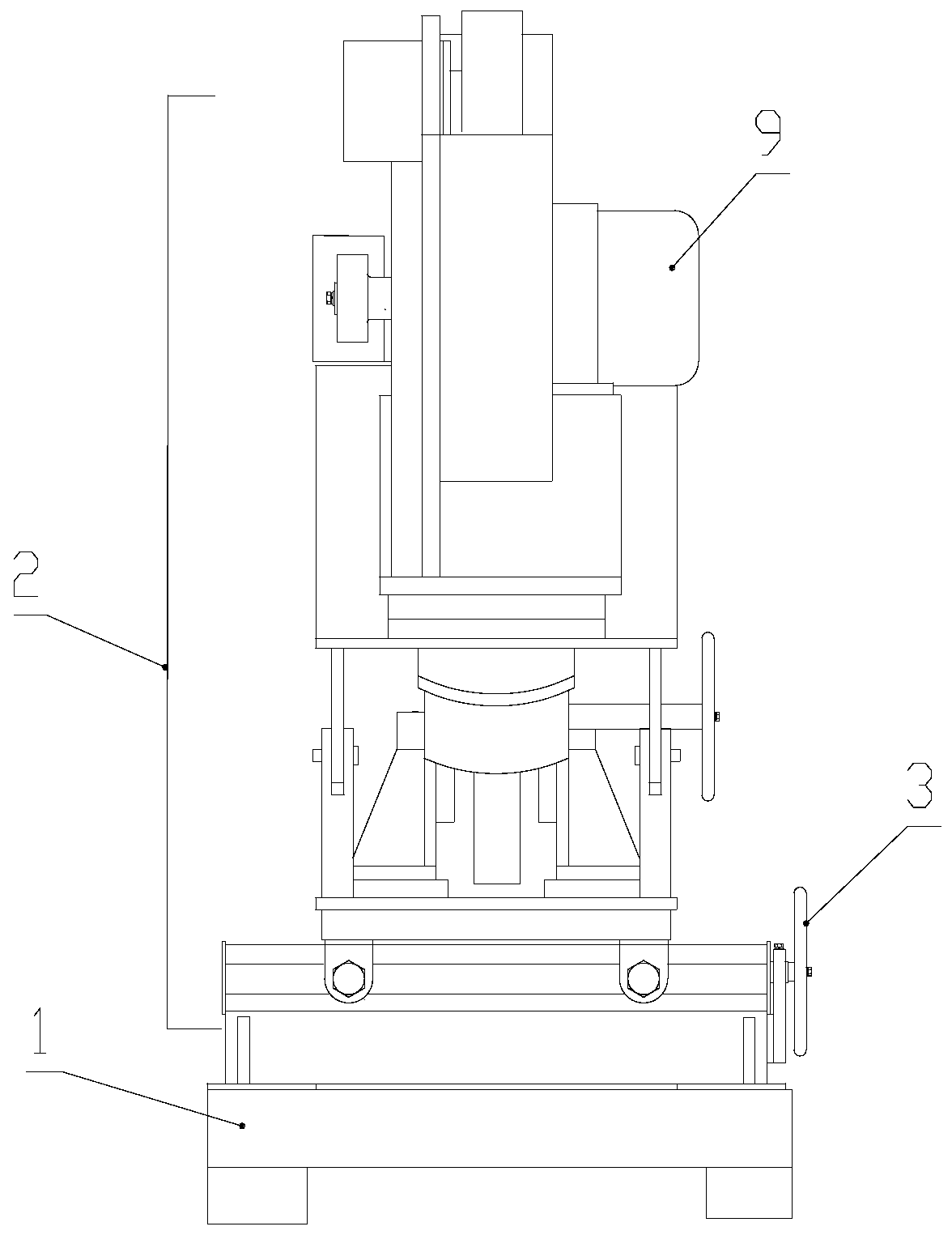

[0023] Such as Figure 1-Figure 3 As shown, a movable airbag-type lifting belt machine, the main body of the belt machine 2 is installed above the traveling car body 1, the main body of the belt machine 2 includes a lateral adjustment component 3, a manual height adjustment component 4, and an air pressure height adjustment component 5 , Angle adjustment assembly 6, belt sander assembly 7.

[0024] Such as figure 1 , the bottom of the lateral adjustment assembly 3 is connected to the top of the traveling vehicle body 1, by rotating the runner of the lateral adjustment assembly 3, the upper plane of the lateral adjustment assembly 3 can be moved laterally, thereby adjusting the horizontal position of the abrasive belt machine, so that the abrasive belt Relatively consistent with the center of the weld.

[0025] The hand-operated height adjustment assembly 4 is connected to the top of the lateral adjustment assembly 3 through the rotating shaft 15. The hand-operated height adj...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap