Method for controlling buckling deformation of automobile exterior trim part mold

A deformation control and exterior trim technology, applied in the coating and other directions, can solve the problems that affect the quality of automobile exterior trim parts and the large warpage value, and achieve the purpose of reducing the warpage deformation value, reducing the elastic modulus, and optimizing the cooling system. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

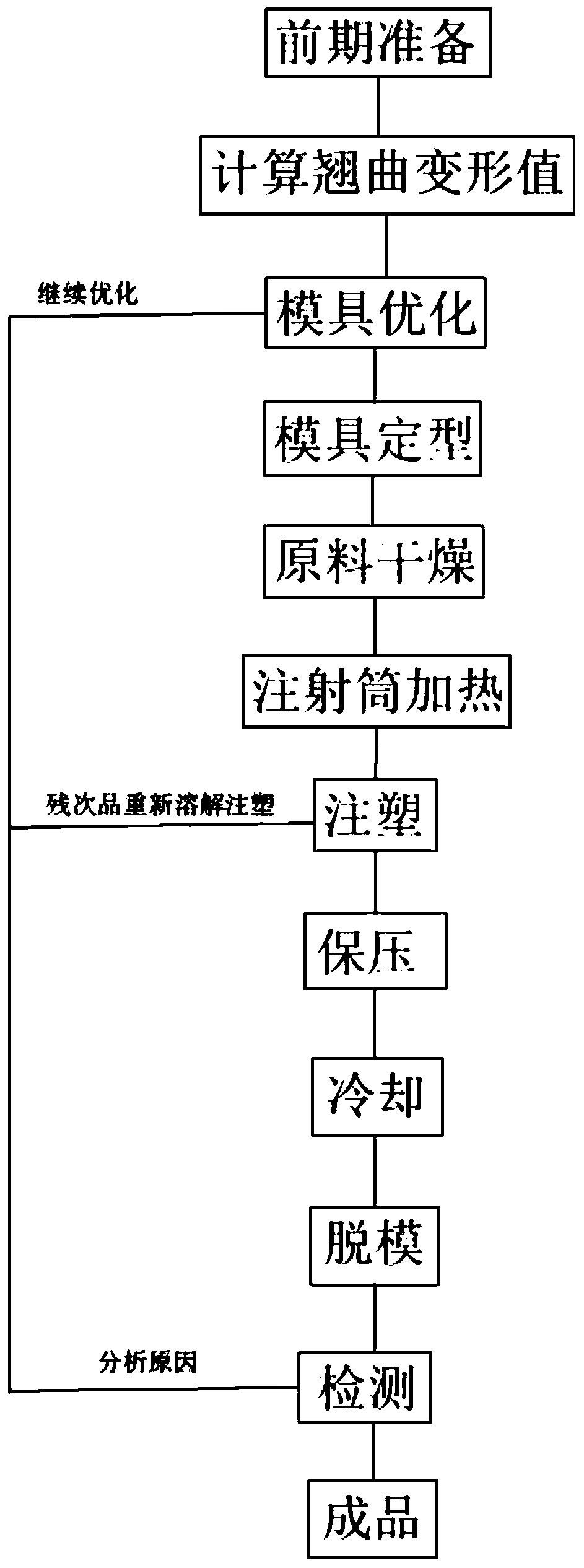

[0029] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0030] A method for controlling the warping deformation of an automotive exterior mold, comprising the following steps:

[0031] (1) Prepare raw materials: determine the raw materials to be used for the automotive exterior parts, the structural shape of the automotive exterior parts, and the design of the basic mold according to the structural shape of the automotive exterior parts. Automotive exterior parts are mainly automotive exterior parts, using polyamide as raw material, polyamide is also called nylon, the melting point of nylon is 230-240°C, and the elastic modulus is 2620MPa; it is a translucent or opaque milky white crystalline polymer with Thermoplastic, lightweight, tough, chemical resistant and durable, also has good abrasion resistance, self-lubrication and solvent resistance.

[0032] Adding 30% glass fib...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com