Shaft head pressing device for replacing printing plate cylinder sleeve

A printing plate cylinder and pressing device technology, which is applied to the general parts of printing machinery, printing, printing machines, etc., can solve the problem of always being located above the fixed end shaft head of the printing plate cylinder, threatening the safety of operators, and production accidents of operators and other issues to achieve the effect of saving manpower, improving safety and saving space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

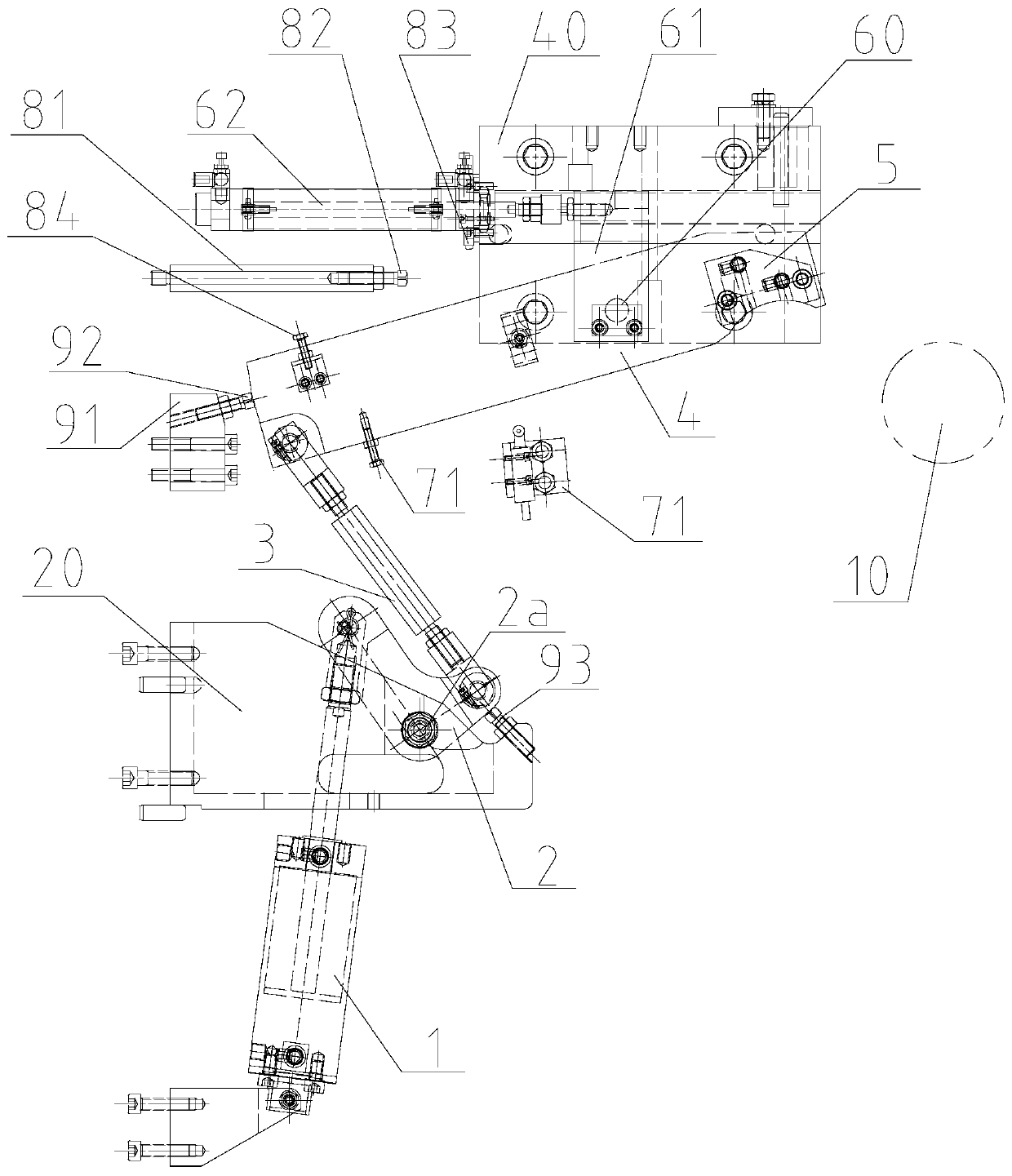

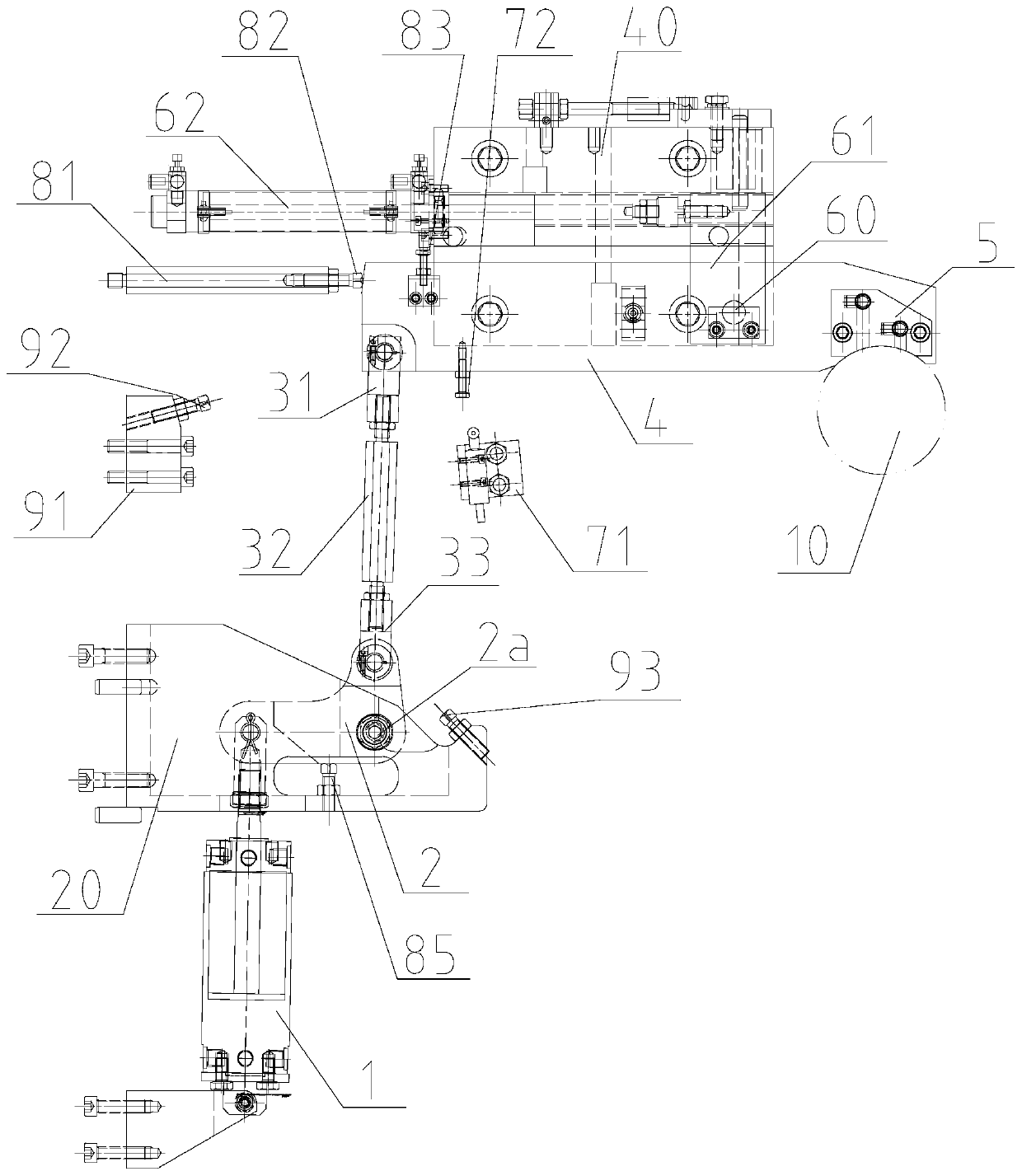

[0015] The present invention will be further described below in conjunction with accompanying drawing.

[0016] see figure 1 and figure 2 , the shaft head pressing device for replacing the printing plate cylinder sleeve of the present invention is installed on the drive side wallboard for installing the fixed end shaft head 10 of the plate cylinder and includes a clutch cylinder 1, a first bracket 2, a connecting rod 3. The compression mechanism, displacement mechanism, position detection mechanism, compression stop mechanism and opening stop mechanism of the second bracket 4 and the briquetting block 5; wherein,

[0017] The bottom end of the clutch cylinder 1 is hinged on the drive side wall plate;

[0018] The first support 2 is composed of a vertical arm and a transverse arm and is L-shaped. The rotating shaft 2a of the first support 2 is located at the junction of the vertical arm and the transverse arm and is hinged on the driving side wall plate through the first fix...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap