Intelligent building block type fermentation warehouse warehouse-in and warehouse-out device

A technology of fermentation warehouse and warehouse storage, applied in storage devices, transportation and packaging, etc., can solve the problems of large occupied space, low production efficiency, low control precision, etc., and achieves the effect of novel structure and reduced labor intensity of workers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

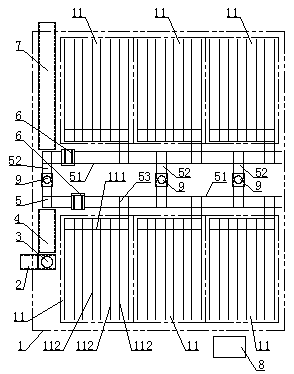

[0007] see figure 1 , the present invention includes a fermentation warehouse 1, and also includes a warehouse-in horizontal roller bed 2, a material box rotating roller bed 3, a warehouse-in longitudinal roller bed 4, a main track system 5, a warehouse-out longitudinal roller bed 7, an electric control box 8, several Stacker truck 6 and several stacker truck rotary roller beds 9, several sub-fermentation warehouses 11 are arranged in the fermentation warehouse 1, and the main track system 5 includes two horizontal double-rails 51 arranged in parallel and several connecting double-rails 52 , several vertical double-tracks 53 of branch lines, sub-horizontal double-tracks 111 and several sub-vertical double-tracks 112 are provided in each sub-fermentation warehouse 11, wireless terminals and PLCs are set in the stacker truck 6, and the horizontal rollers entering the warehouse The left part of the bed 2 stretches out from the left side wall of the fermentation storehouse 1, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com