Preparation process of cement-based grouting material using kaolin

A preparation process and kaolin technology, applied in the field of preparation technology of cement-based grouting materials, can solve the problems of high cost, closely related metakaolin, complicated selection process of high-quality kaolin resources, etc., and achieve the effect of low cost and mining application value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

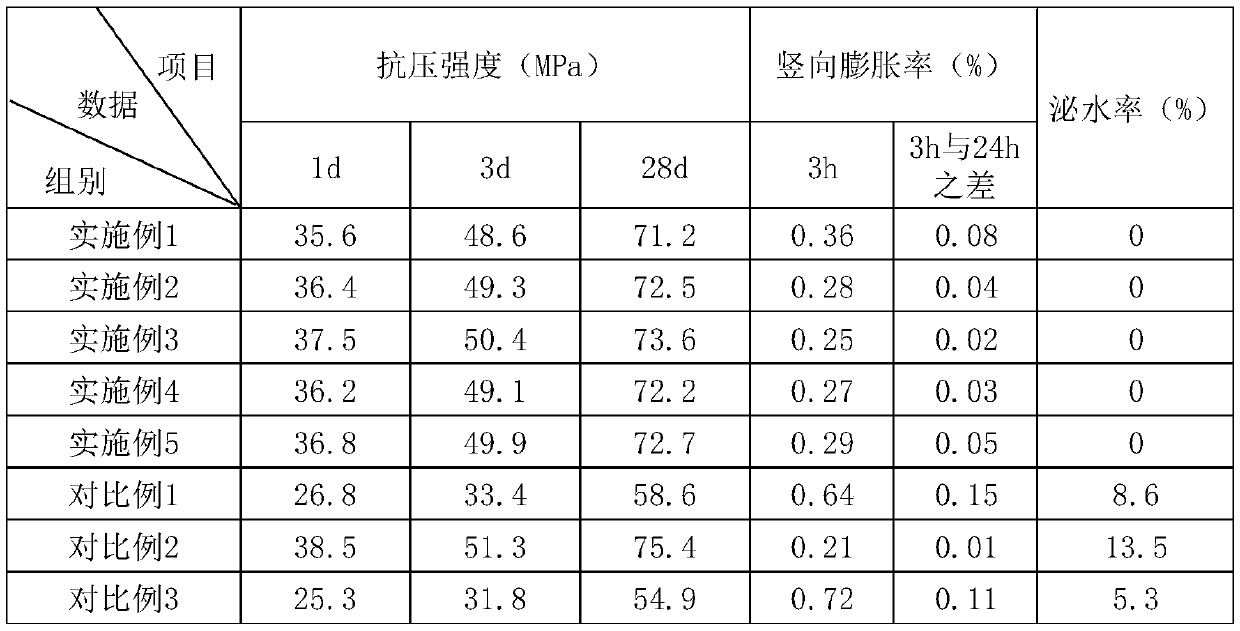

Examples

Embodiment 1

[0043] A preparation process for cement-based grouting material using kaolin, comprising the following steps:

[0044] S1. Screening kaolin: screen the slurry part of kaolin ore to obtain powder, after drying, break up through a powder modifier and pass through a 325 mesh sieve to obtain kaolin with a powder content of 50% below 2 μm;

[0045] S2. Kaolin activation treatment:

[0046] (1) Calcination in the first stage: the kaolin in step S1 is calcined in the first stage, the calcination temperature T1 is 690°C, and the calcination time t1 is 80min;

[0047] (2) Calcination in the second stage: The kaolin obtained in the stage (1) is calcined in the second stage. The calcination in the second stage is divided into the first half and the second half. The calcination temperature T2 of the first half is 740 ° C and the calcination time is t2 100min, the calcination temperature of the second half is 740°C, the calcination time is 100min, the interval between the first half and the...

Embodiment 2

[0054] A preparation process for cement-based grouting material using kaolin, comprising the following steps:

[0055] S1. Screening kaolin: screen the slurry part of kaolin ore to obtain powder, after drying, break up through a powder modifier and pass through a 325 mesh sieve to obtain kaolin with a powder content of 54% below 2 μm;

[0056] S2. Kaolin activation treatment:

[0057] (1) Calcination in the first stage: the kaolin in the step S1 is calcined in the first stage, the calcination temperature T1 is 695°C, and the calcination time t1 is 85min;

[0058] (2) Calcination in the second stage: The kaolin obtained in the stage (1) is calcined in the second stage. The calcination in the second stage is divided into the first half and the second half. The calcination temperature T2 of the first half is 745 ° C and the calcination time is t2 100min, the calcination temperature of the second half is 745°C, the calcination time is 105min, the interval between the first half a...

Embodiment 3

[0065] A preparation process for cement-based grouting material using kaolin, comprising the following steps:

[0066] S1. Screening kaolin: screen the slurry part of kaolin ore to obtain powder, after drying, break up through a powder modifier and pass through a 325 mesh sieve to obtain kaolin with a powder content of 54% below 2 μm;

[0067] S2. Kaolin activation treatment:

[0068] (1) Calcination in the first stage: the kaolin in step S1 is calcined in the first stage, the calcination temperature T1 is 700°C, and the calcination time t1 is 90min;

[0069] (2) Calcination in the second stage: The kaolin obtained in the stage (1) is calcined in the second stage. The calcination in the second stage is divided into the first half and the second half. The calcination temperature T2 of the first half is 750 ° C and the calcination time is t2 105min, the calcination temperature of the second half is 750°C, the calcination time is 105min, the interval between the first half and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com