Crack self-repairing concrete and preparation and repairing method thereof

A repair method and concrete technology, which is applied in building maintenance, construction, building construction, etc., can solve the problems of slow calcium carbonate deposition rate and long self-repair period of cracks, so as to prevent expansion, improve impermeability performance, and increase deposition rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

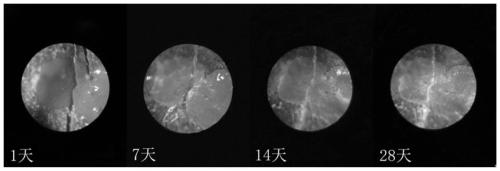

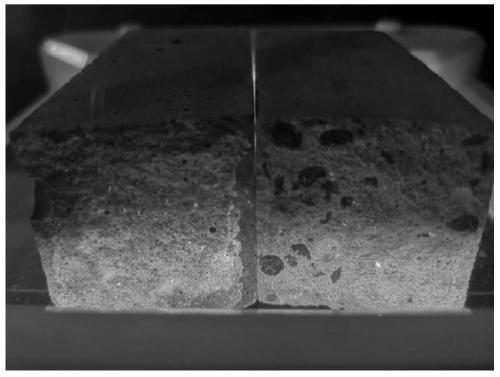

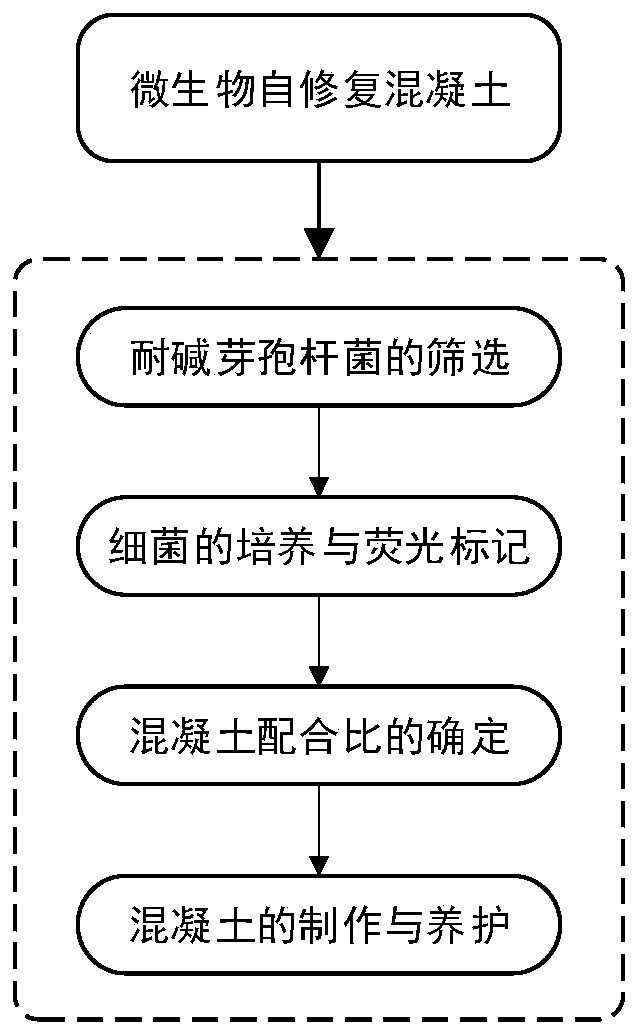

Method used

Image

Examples

Embodiment 1

[0022] Step 1: Select Bacillus pasteurii (Sporosarcina pasteurii, ATCC11859) with the function of mineralization and precipitation as the freeze-dried powder of the bacteria. Before use, the bacteria should be activated according to the microbial culture method. The specific process is as follows:

[0023] (1) Culture medium configuration. The content of each component in the medium is as follows: 1 L of ultrapure water, 5 g of peptone, 3 g of beef extract, 0.53 g of sodium carbonate, 0.42 g of sodium bicarbonate, and 18 g of agar powder.

[0024] (2) Sterilize the culture medium and utensils. Place the remaining utensils (glass plates, centrifuge tubes, pipette tips, etc.) and culture medium required for the experiment in a pressure cooker, and sterilize at 121° C. for 20 minutes.

[0025] (3) Invert the plate. Before the culture medium containing agar powder is cooled and solidified, an agar plate for activation of Bacillus is prepared in the ultra-clean bench according to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com