Catalyst component and catalyst for olefin polymerization, applications of catalyst component and catalyst, and olefin polymerization method

A technology of olefin polymerization and catalyst, which is applied in the field of olefin polymerization and olefin polymerization catalysts, can solve the problems of low isotacticity of polypropylene, poor stereo-orientation ability, difficult high melt index products, etc., and achieve high melt flow index , high stereospecificity, and high hydrogen sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

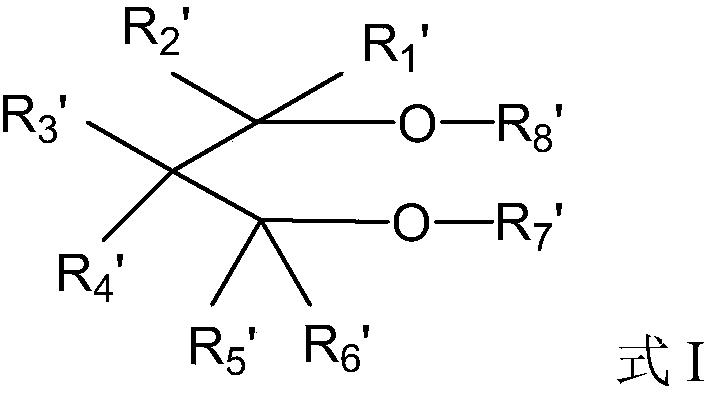

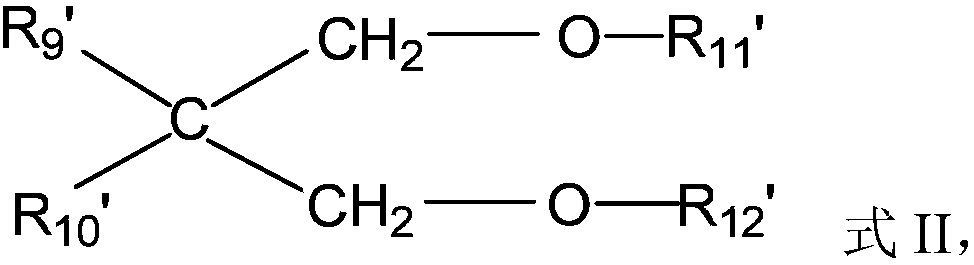

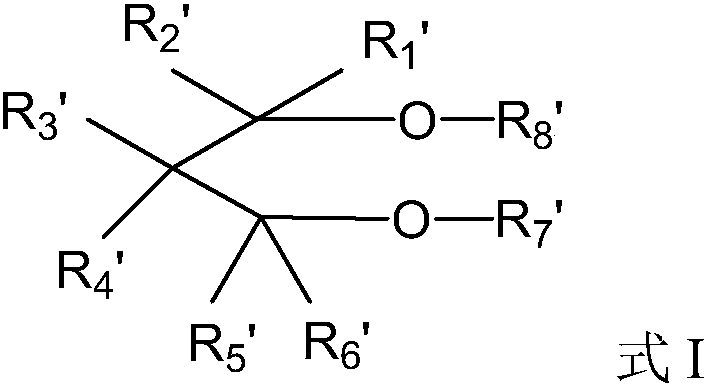

Method used

Image

Examples

Embodiment 1~4 and comparative example 1~4

[0073] (1) Preparation of solid catalyst component a

[0074] In the reactor fully replaced by high-purity nitrogen, add 4.8g of magnesium chloride, 95mL of toluene, 4mL of epichlorohydrin, and 12.5mL of tributyl phosphate in sequence, and raise the temperature to 50°C while stirring, and maintain it for 2.5h. The solid is completely dissolved. Add 1.4 g of phthalic anhydride and continue for 1 h. Cool the solution to below -25°C, add 56mL TiCl dropwise within 1h 4 , slowly raised the temperature to 80°C, and gradually precipitated solids during the heating process, added 10 mmol of the complex internal electron donor compound in Table 1, maintained the temperature for 1 h, filtered, and washed twice with 70 mL of toluene to obtain solid precipitates. Then add 60mL toluene, 40mL TiCl 4 , the temperature was raised to 110°C and maintained for 2h, the same operation was repeated once, and then washed three times with 70mL toluene at 110°C for 10min each, and then 60mL of hexan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com