A concrete automatic leveling method and an intelligent leveling robot using the same

A concrete container and concrete technology, which is applied in the processing of building materials, roads, buildings, etc., can solve the problems of high labor intensity, low efficiency and influence, and achieve the effect of improving the leveling effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

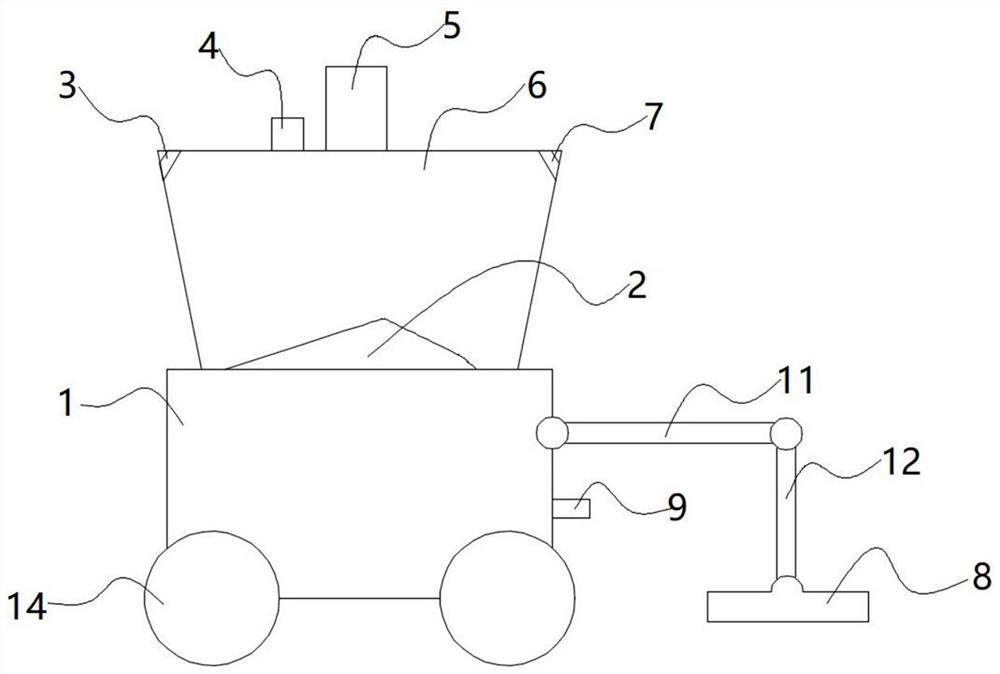

[0042] Such as Figure 2-4 As shown, the present embodiment provides an intelligent leveling robot, which includes a leveling robot main body 1, a concrete container 6, a slump detection device and a leveling mechanism 8, wherein,

[0043] The leveling robot main body 1 is used to load the concrete 2 to be poured. The front side of the leveling robot main body 1 is provided with a concrete outlet 9. 13 on the concrete floor.

[0044] The concrete container 6 is arranged above the leveling robot main body 1, and is used for loading the concrete 2 to be detected. Preferably, the concrete container 6 is provided with a conditioner inlet 4 for adjusting slump. In this embodiment, the conditioner inlet is further preferred. 4 is arranged above the concrete container 6 for adding concrete slump regulator.

[0045] Preferably, the slump regulator mainly includes water and different types of concrete, and more preferably, the slump regulator mainly includes water, cement slurry, san...

Embodiment 2

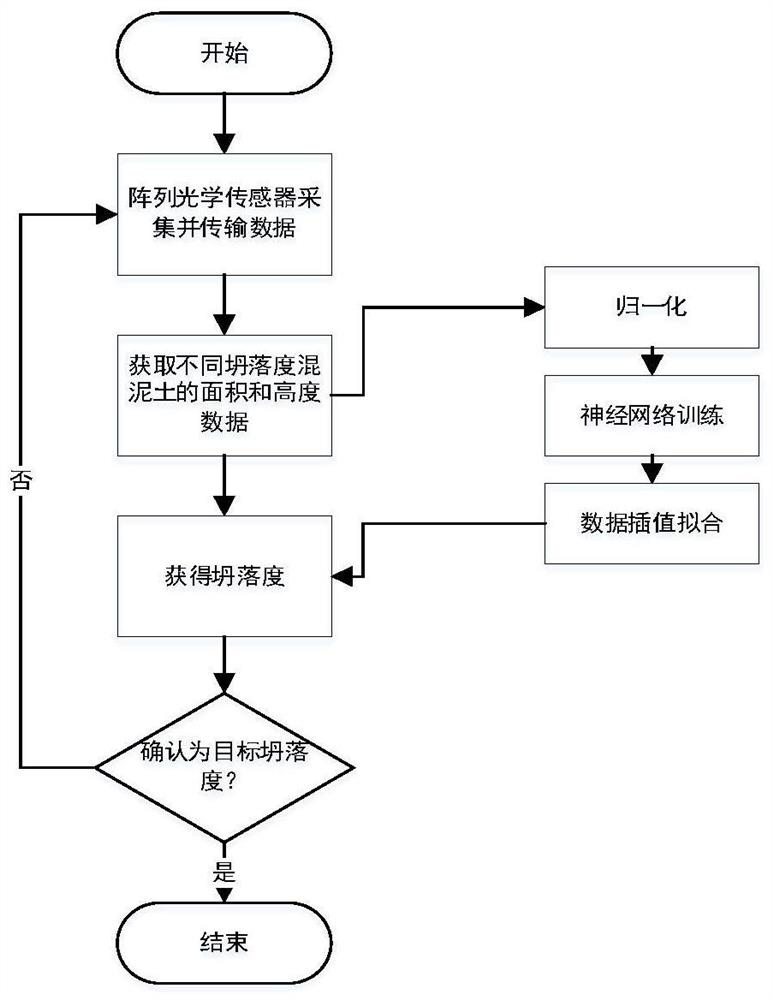

[0055] Such as figure 1 As shown, the present embodiment provides a concrete automatic leveling method, adopts the intelligent leveling robot provided in embodiment 1, is provided with a concrete container 6 and a slump detection device on the intelligent leveling robot, and implements the following control:

[0056] S1: Detect the concrete slump in the concrete container 6, if it is detected that the concrete slump is within the preset range, execute step S3; if not within the preset range, execute step S2.

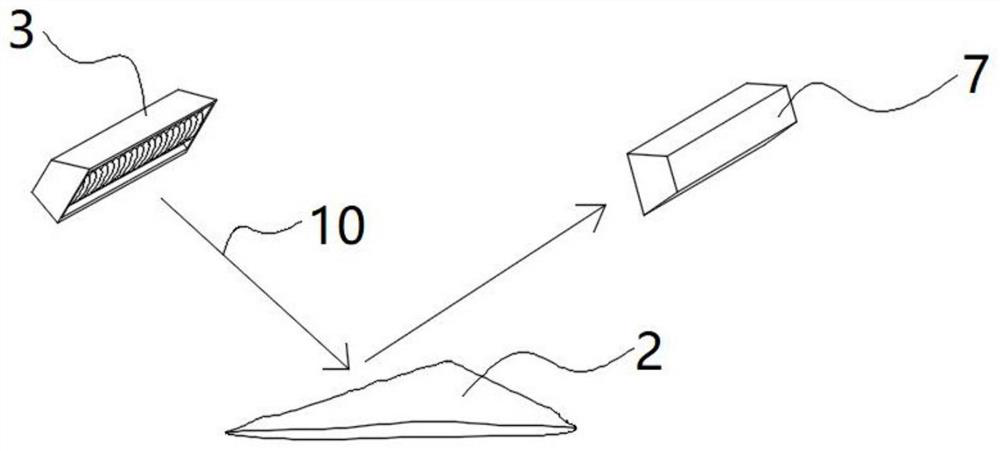

[0057] Specifically, a certain amount of concrete 2 is placed in the concrete container 6 through the concrete inlet 5, the array optical sensor emitting end 3 emits a light beam 10 to irradiate the surface of the concrete 2, and the array optical sensor receiving end 7 receives the reflected light beam 10, thereby Scan the expansion degree and height of the surface of concrete 2, and transmit the scanned expansion degree and height data to the central processor database...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com