Turbine blade honeycomb spiral cavity cooling structure

A technology for turbine blades and cooling structures, applied in the direction of blade support components, air transportation, engine functions, etc., can solve the problems of large flow resistance, difficult manufacturing, complex structure, etc., improve the efficiency of the whole machine, eliminate mutual impact and Good blending and body-fitting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

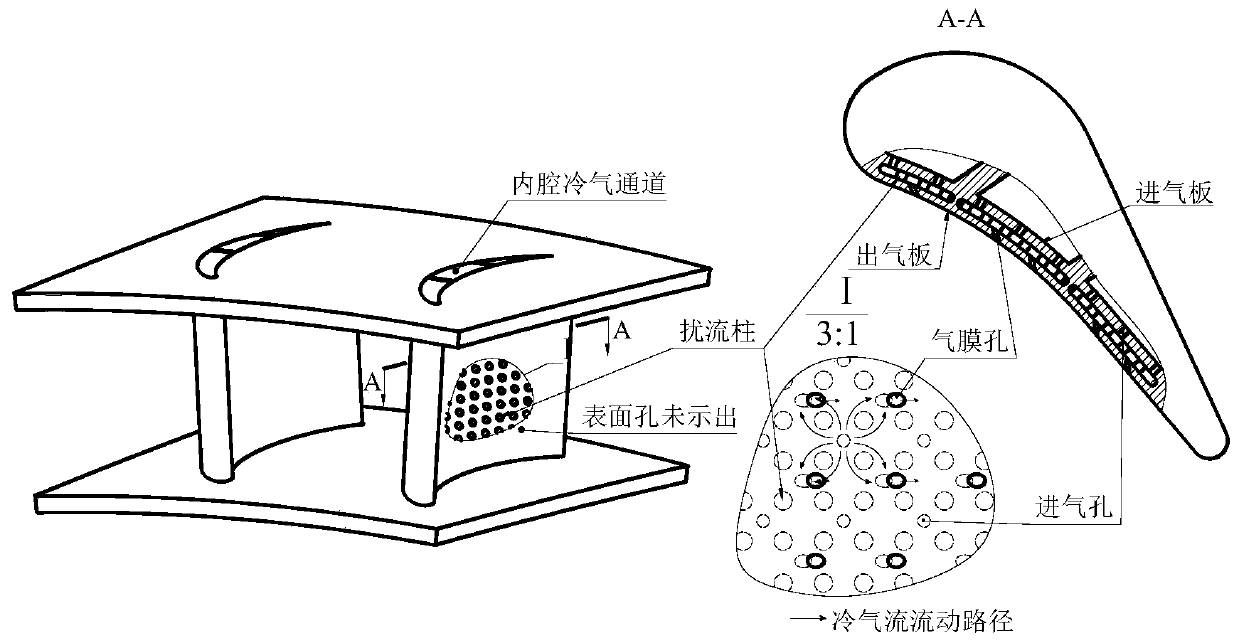

[0041] The present invention conducts a comparative study on the internal cooling air flow state of the conventional laminate structure and the honeycomb spiral cavity structure in the present invention through three-dimensional numerical simulation, as shown in Figure 7 (a) and Figure 7 (b) comparative analysis, it can be known that the present invention The cross-sectional area of the intercooler air channel is roughly the same along the way, there will be no flow abruptness and throttling, and the airflow turning angle is small and there is no mutual impact and mixing, so the resistance of the relative laminate structure is smaller.

Embodiment 2

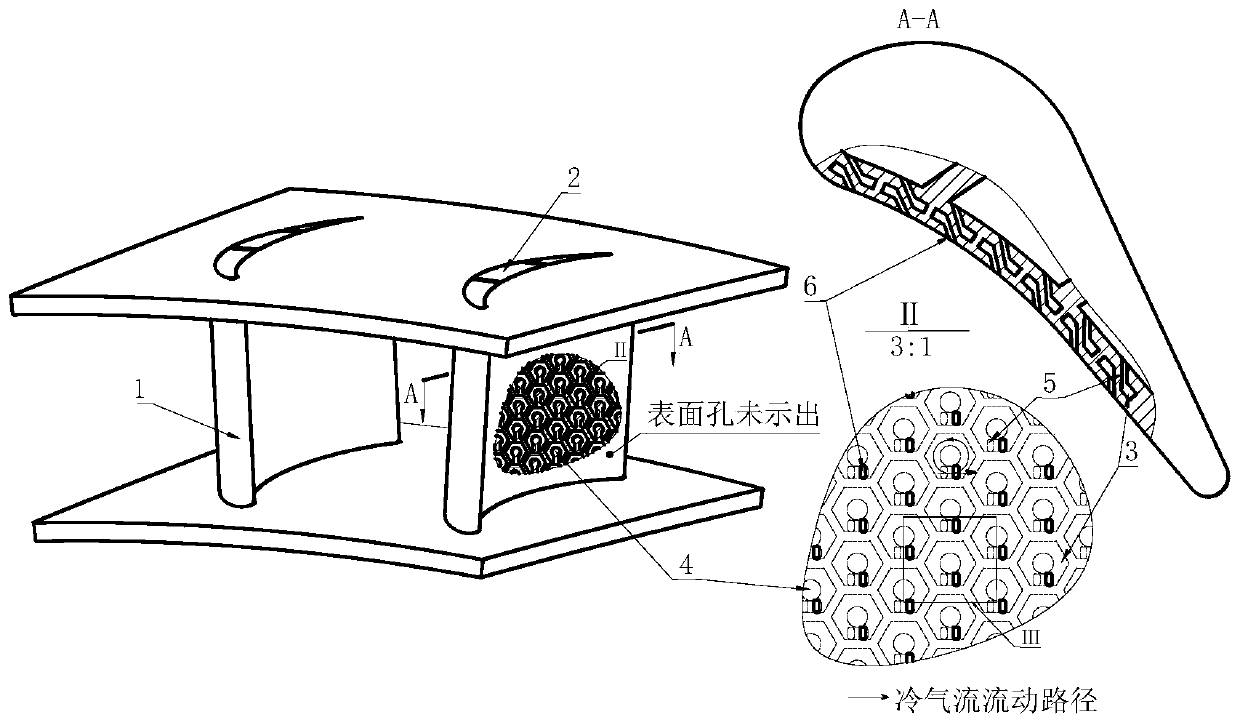

[0043] As shown in Figure 2, the cooling structure of the turbine blade honeycomb spiral cavity includes a hollow turbine blade 1, a honeycomb spiral cavity 3 and a spoiler column 4;

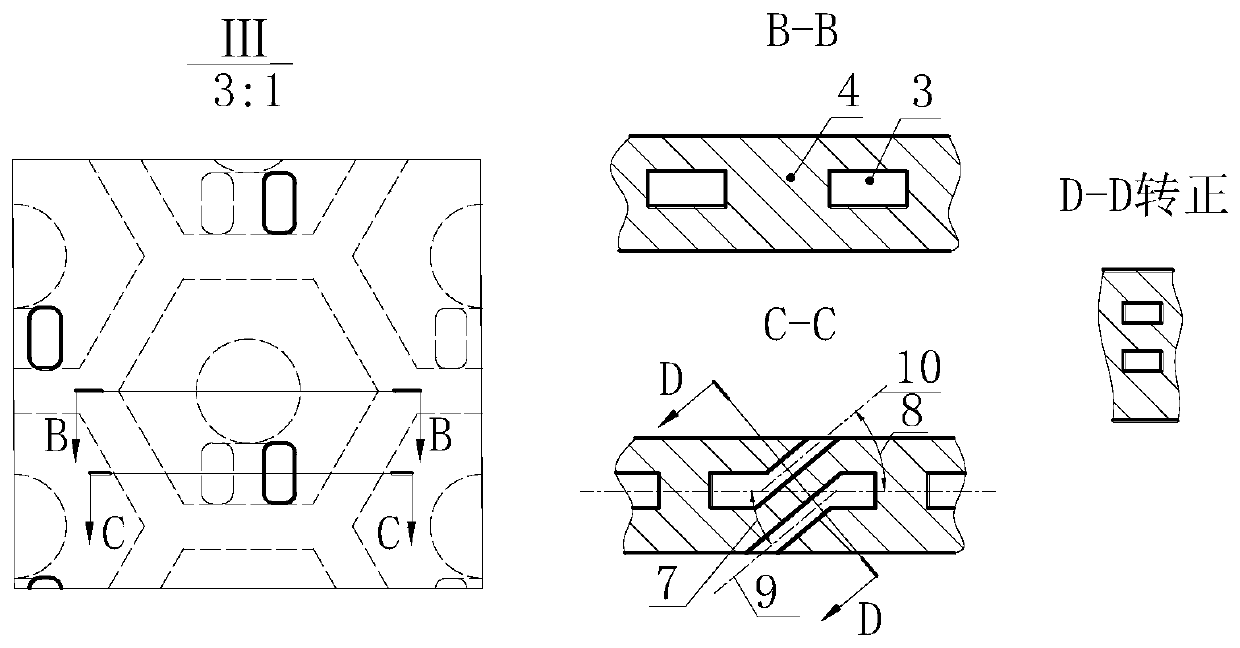

[0044] The inside of the hollow turbine blade 1 is provided with a cold air channel 2, and a plurality of arrays of honeycomb spiral chambers 3 are arranged in the blade wall of the hollow turbine blade 1, and the center of the honeycomb spiral chamber 3 is provided with a spoiler column 4, and the spoiler column 4 is a cylindrical structure, each honeycomb spiral chamber 3 is a unit body, each honeycomb spiral chamber 3 is approximately regular hexagonal in shape, and a plurality of unit bodies are arranged in a honeycomb shape, and in each unit body, the air intake The hole 5 and the air outlet hole 6 are respectively located on both sides of the blade wall, and the centerline 9 of the air inlet hole and the centerline 10 of the air outlet hole are parallel in the same vertical plane. The cros...

Embodiment 3

[0046] The cooling structure of the turbine blade honeycomb spiral cavity includes a hollow turbine blade 1, a honeycomb spiral cavity 3 and a spoiler column 4; the inside of the hollow turbine blade 1 is provided with a cold air passage 2, and the blade wall of the hollow turbine blade 1 is provided with There are multiple arrays of honeycomb spiral chambers 3, and the center of the honeycomb spiral chamber 3 is provided with a spoiler column 4. The spoiler column 4 is a cylindrical structure, and each honeycomb spiral chamber 3 is a unit body, and each honeycomb spiral chamber 3 is shaped like a square In each unit body, the air inlet 5 and the air outlet 6 are respectively located on both sides of the blade wall, and the centerline 9 of the air inlet and the centerline 10 of the air outlet parallel in the same vertical plane. The included angles between the central line 9 of the air inlet hole and the central line 10 of the air outlet hole and the horizontal plane are the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com