Air cylinder seat assembly, compressor and refrigeration equipment

A technology of a cylinder block and a compressor, applied in the field of compressors, can solve problems such as being unfavorable for increasing the volume of a refrigerator box, a low degree of miniaturization, and a large compressor volume, so as to reduce the risk of cylinder collision, fully utilize the space, and achieve a small volume. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

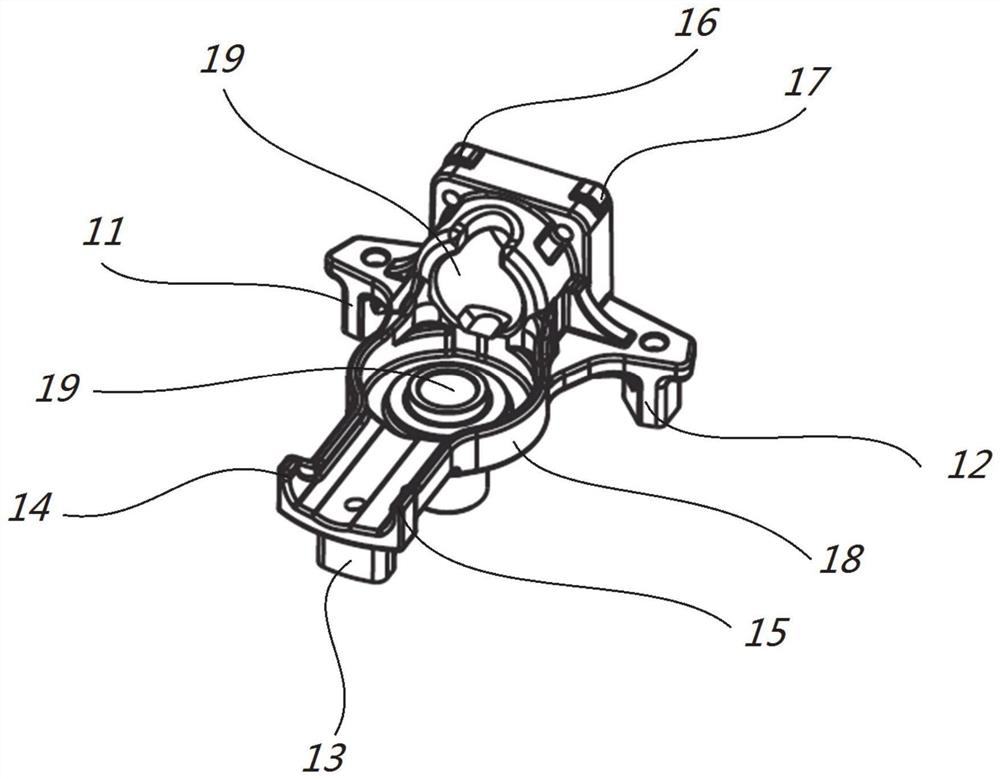

[0029] In a typical implementation of the present invention, Example 1 discloses a cylinder block assembly for a compressor, which includes a main body of a cylinder block 1, and three legs are provided on the bottom side of the main body of the cylinder block 1. In this embodiment, , the three legs are respectively called the first leg 13, the second leg 11 and the third leg 12, and the projection points of the central axes of the three legs on the plane are distributed in an isosceles triangle; The main body of the cylinder block 1 also has three protrusions protruding from the main body of the cylinder block 1. In this embodiment, the three protrusions are named as the first protrusion, the second protrusion and the third protrusion respectively. The bottom side is connected to the first leg 13 , the bottom side of the second protrusion is connected to the second leg 11 , and the bottom side of the third protrusion is connected to the third leg 12 .

[0030] By using three ...

Embodiment 2

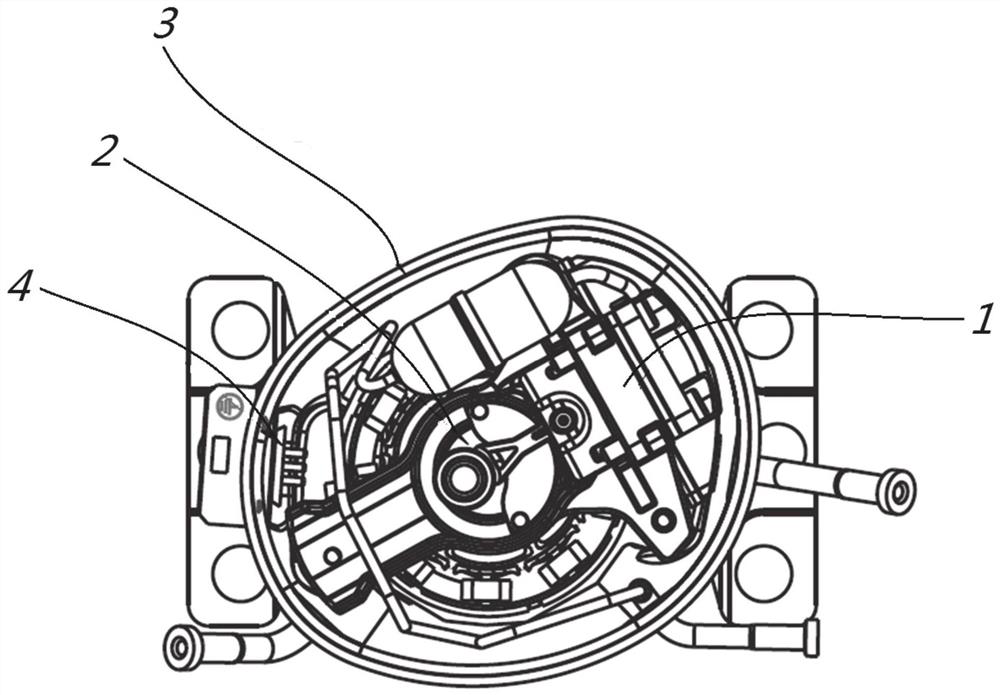

[0043] In a typical implementation of the present invention, Example 2 discloses a compressor, the compressor includes a cylinder block assembly, a cylinder head, a motor, a crankshaft 2, a connecting rod, a piston and a casing, wherein the cylinder block assembly is The cylinder block assembly described in Embodiment 1 The cylinder block assembly, the cylinder head, the motor, the crankshaft 2, the connecting rod, and the piston are all arranged in the casing, the crankshaft 2 passes through the through hole 18 in the center of the cylinder block assembly, and the casing is connected There are exhaust pipes and suction pipes; when the reciprocating compressor is working, the working medium is continuously inhaled by the suction pipe, and discharged from the exhaust pipe after being compressed; the cylinder block 1 is provided with a cylinder hole; the motor, crankshaft 2, connecting The rod and the piston form a drive assembly. During operation, the motor drives the crankshaft...

Embodiment 3

[0050] In a typical implementation of the present invention, Example 3 discloses a refrigeration equipment, including the compressor described in Example 2. Refrigeration equipment can be in the form of refrigerators, air conditioners, freezers and other products.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com