Device for testing sealing performance, pressure resistance and opening pressure of automobile electromagnetic valve

A technology of opening pressure and testing equipment, which is applied in fluid tightness testing, measuring equipment, using stable tension/pressure to test material strength, etc., to achieve low cost, convenient operation, and improved performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

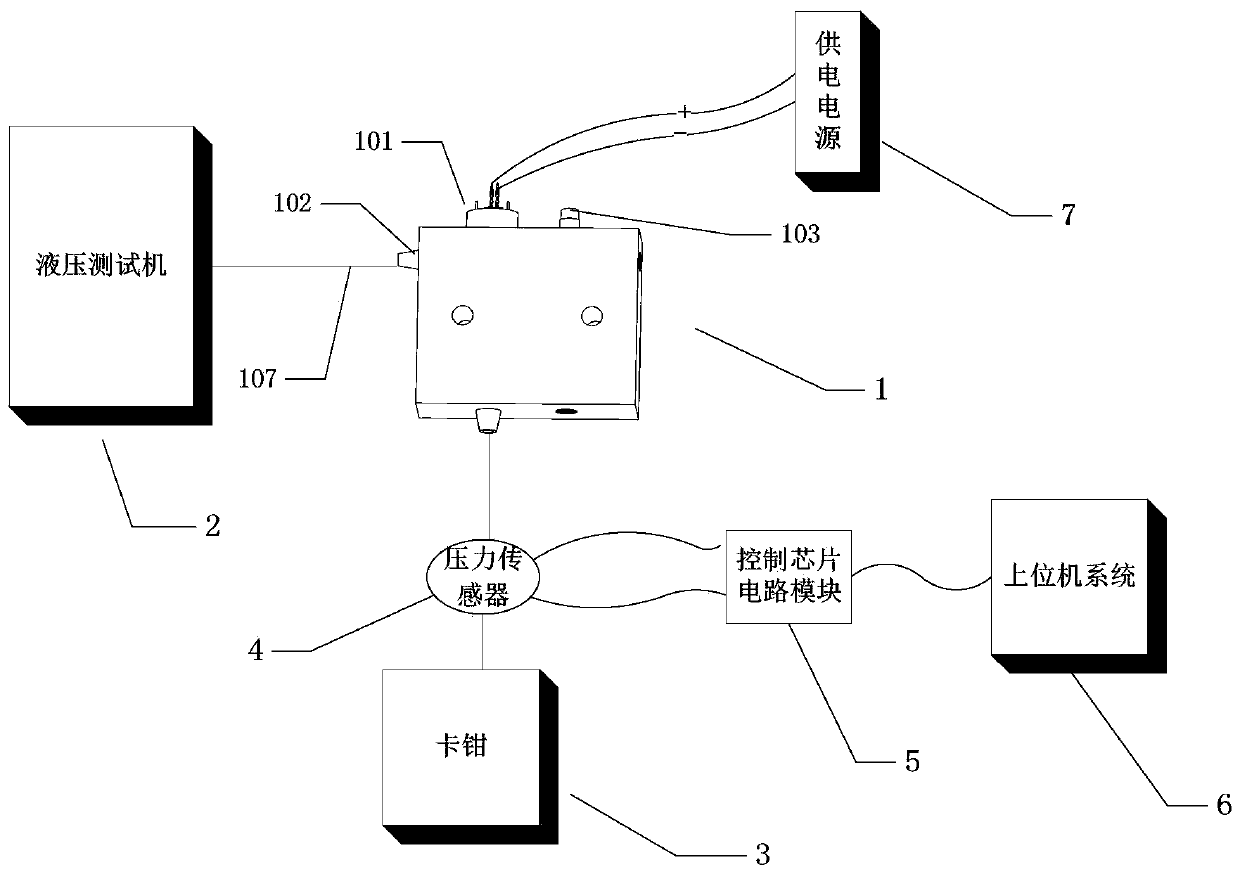

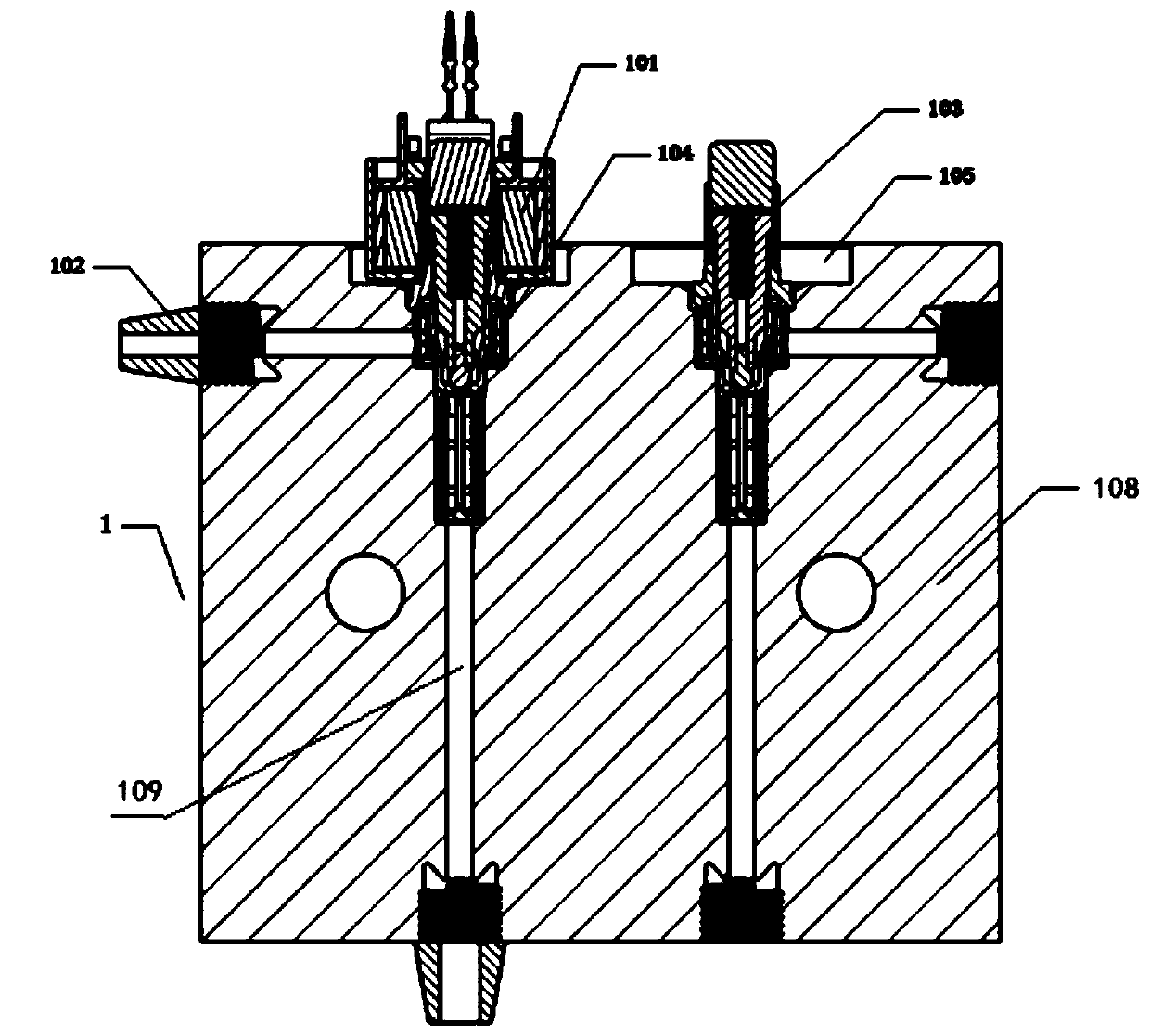

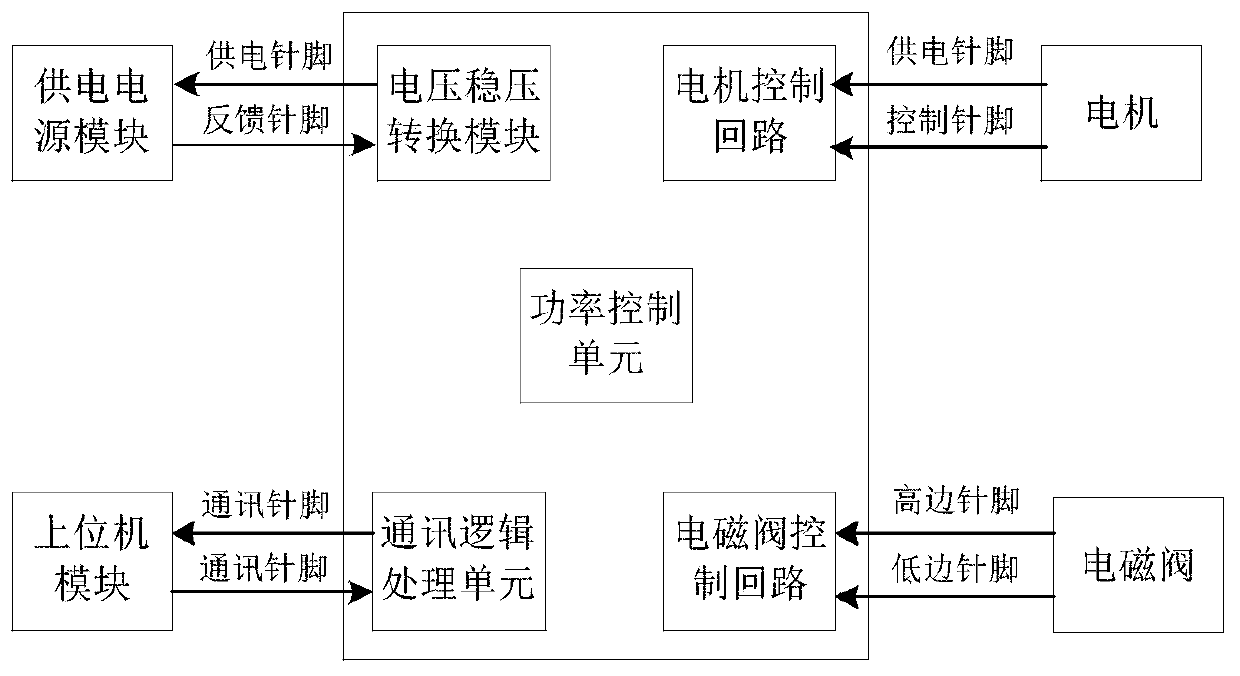

[0026] For a normally open valve, when using the present invention to detect the sealing performance of the solenoid valve, the solenoid valve 103 is first riveted into the test valve block 1, and then the liquid inlet and the liquid outlet of the test valve block 1 are respectively connected to Hydraulic testing machine 2 and brake caliper 3. The solenoid valve coil 101 is sleeved on the solenoid valve 103, and the two stages of the solenoid valve coil 101 are connected to the positive and negative electrodes of the power supply 7 respectively. Connect the pressure sensor module 4 to the control chip circuit module 5, and then connect it to the upper computer module 6. Use the brake caliper 3 to vent the bolt, start the hydraulic testing machine 1, pressurize it to 60 or 120 bar, then turn on the power supply 7, the solenoid valve coil 101 is powered on, the hydraulic circuit is closed, and the pressure source of the hydraulic testing machine 1 is cut off at this time , Throu...

Embodiment 2

[0028] For a normally closed valve, when using the present invention to detect the sealing performance of the solenoid valve, the solenoid valve 103 is first riveted into the test valve block 1, and then the liquid inlet and the liquid outlet of the test valve block 1 are respectively connected to Hydraulic testing machine 2 and brake caliper 3. The solenoid valve coil 101 is sleeved on the solenoid valve 103, and the two stages of the solenoid valve coil 101 are connected to the positive and negative electrodes of the power supply 7 respectively. Connect the pressure sensor module 4 to the control chip circuit module 5, and then connect it to the upper computer module 6. Use the brake caliper 3 to vent the bolt, turn on the power supply 7, the solenoid valve coil 101 is powered on, the hydraulic circuit is opened, the hydraulic press is started, pressurized to 60 or 120 bar, then the power is turned off, and the pressure source of the hydraulic testing machine 2 is cut off. T...

Embodiment 3

[0030] When using the present invention to test the pressure resistance of the solenoid valve, the solenoid valve 103 is first riveted into the test valve block 1, and then the liquid inlet and the liquid outlet of the test valve block 1 are respectively connected to the hydraulic tester using the high-pressure adapter 102 2 and brake calipers 3. The solenoid valve coil 101 is sleeved on the solenoid valve 103, and the two stages of the solenoid valve coil 101 are connected to the positive and negative electrodes of the power supply 7 respectively. Use the brake caliper 3 to exhaust the air, then turn on the power supply 7, and the solenoid valve coil 101 is powered on with 3.5A current. After opening the solenoid valve 103, it is adjusted to a 1A maintenance current. Start the test machine and adjust the pressure to 300bar±5bar (30MPa) ), after maintaining the pressure for 20s, release the pressure, and observe whether there is any deformation and leakage on the surface of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com