Nondestructive testing method for lithium precipitation of lithium ion battery

A lithium-ion battery, non-destructive testing technology, applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., to achieve the effect of simple and easy to understand, optimize battery design and charging method, and improve accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] A non-destructive testing method for analyzing lithium in a lithium-ion battery, comprising the steps of:

[0055] S1. Use a 2.28Ah-435573 soft-packaged lithium-ion battery as the soft-packaged lithium-ion battery to be tested, discharge the soft-packaged lithium-ion battery to be tested at 0.2C to 2.5V, and then let it stand for 10 minutes;

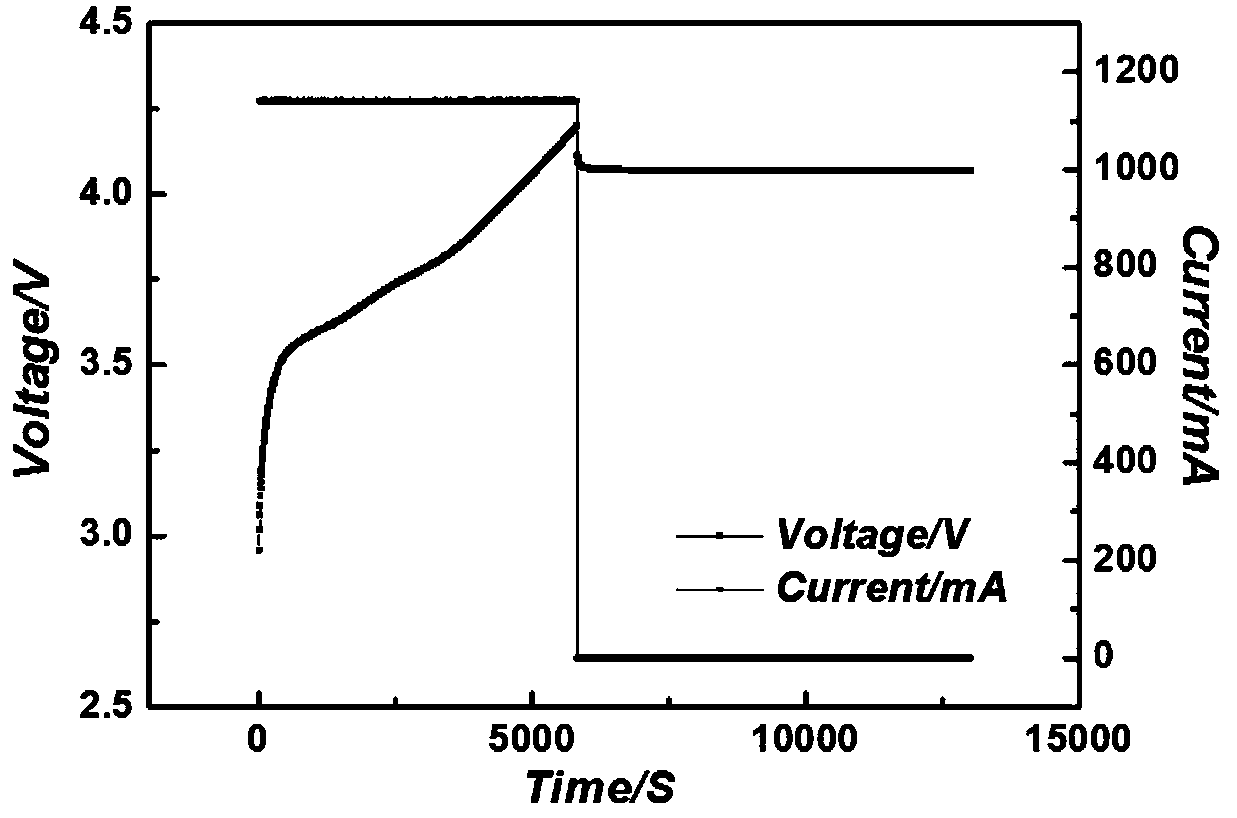

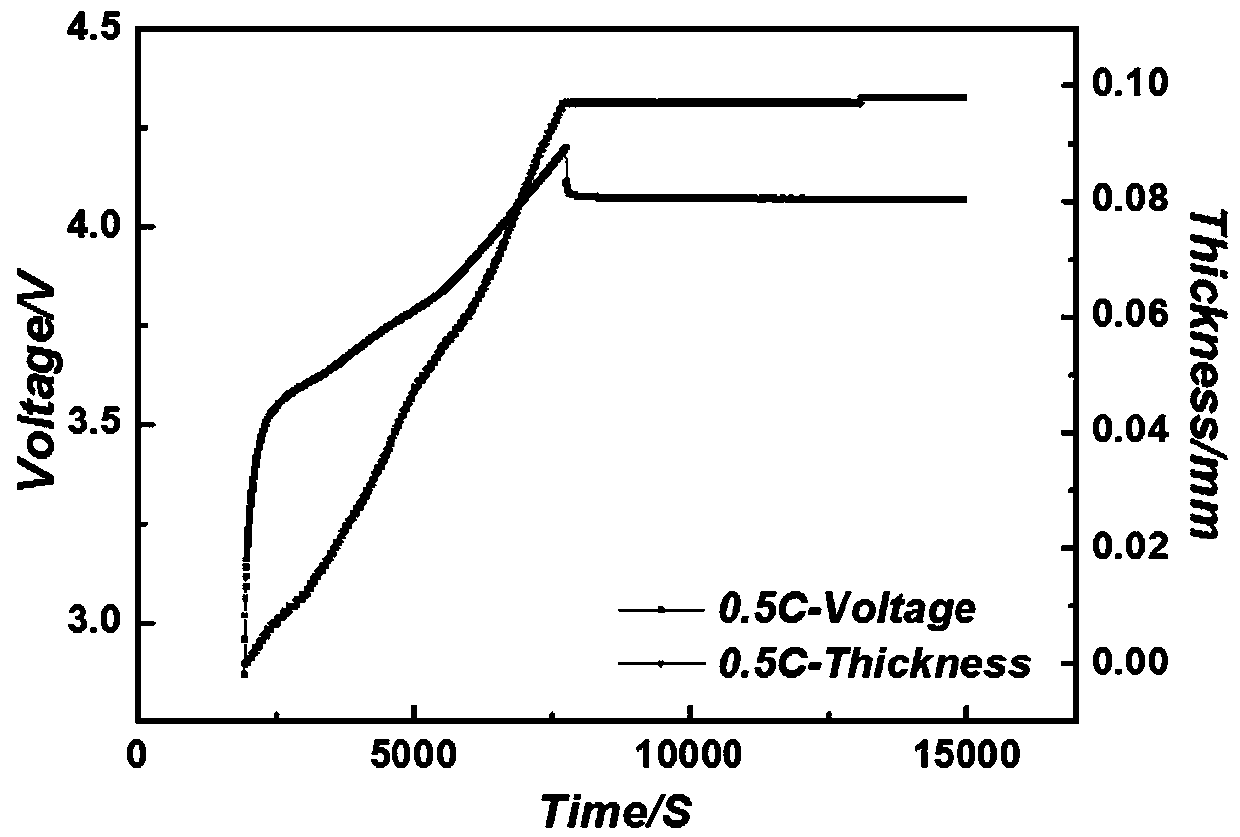

[0056] S2. Charge the soft-packaged lithium-ion battery to be tested at a constant current of 0.5C to the set charging cut-off voltage of 4.2V, and then let it stand for 2 hours;

[0057] S2. During the charging process and the standing process, collect the thickness and voltage of the soft-packaged lithium-ion battery to be tested in real time, draw the thickness curve of the thickness with time in the same coordinate system, and the voltage with time. Time-varying voltage curves;

[0058] S3. If in the thickness graph, the thickness first decreases with time and then remains stable during the standing process after charging, th...

Embodiment 2

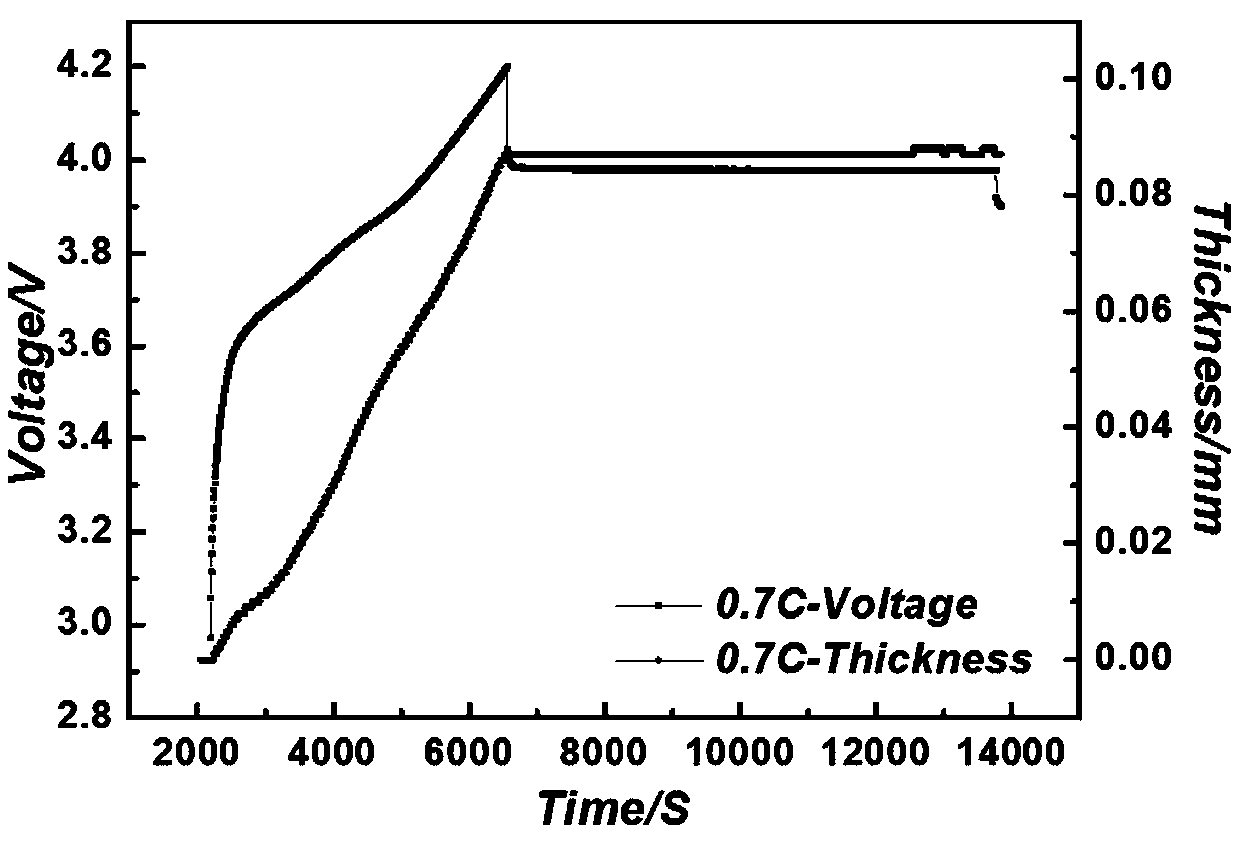

[0062] Based on Example 1, the only difference is that in step S2, the soft-packaged lithium-ion battery to be tested is charged at a constant current of 0.7C to the set charge cut-off voltage of 4.2V, and then left to stand for 2h.

Embodiment 3

[0064] Based on Example 1, the only difference is that in step S2, the soft-packaged lithium-ion battery to be tested was charged at a constant current of 1C to the set charging cut-off voltage of 4.2V, and then stood still for 2h.

[0065] figure 2 The thickness graph and the voltage graph provided for Embodiment 1 of the present invention, such as figure 2 As shown, the thickness of the soft-packaged lithium-ion battery to be tested gradually increases with constant current charging. After charging to a cut-off voltage of 4.2V, it is allowed to stand still for 2 hours. During the standing period, the voltage decreases to a certain extent due to the influence of polarization. , the thickness of the soft-packaged lithium-ion battery to be tested remains basically unchanged, indicating that there will be no lithium precipitation on the surface of the negative electrode when the battery is charged under the condition of charging at this charging rate.

[0066] image 3 The t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com