Power equipment image data warehouse and power equipment defect detection method

A technology for power equipment and image data, which is applied in the field of power equipment image data warehouse and power equipment defect detection, can solve the problems of data waste, low data value density, excessive time and energy, etc., to reduce pressure, improve efficiency and accuracy Sexual, easy-to-expand effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

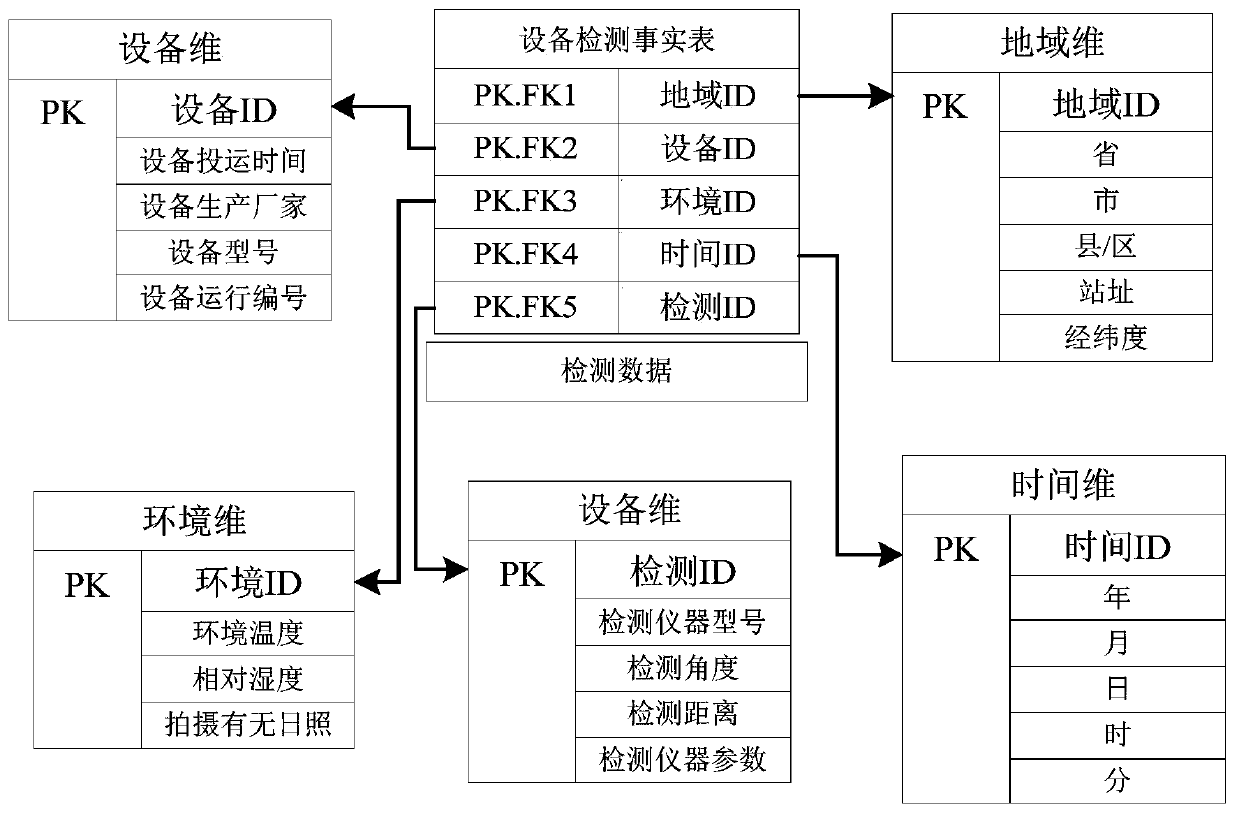

[0032] This embodiment provides a power equipment image data warehouse, which stores detection images of multi-dimensional data star model organization modes, and each detection image is associated with a priori information features for the image analysis, including the corresponding The operating information, time information, geographical information, environmental monitoring information and detection information of the tested equipment, the operating information of the tested equipment, time information, geographic system corresponding information, environmental monitoring data and detection information have unique signs for indexing. The data storage structure of the data warehouse is as follows: figure 1 As shown, the data storage structure forms a multi-dimensional data star model organization mode with five dimensions of time, region, environment, equipment, and detection.

[0033] Data warehouse is a technology that can access various databases and integrate various so...

Embodiment 2

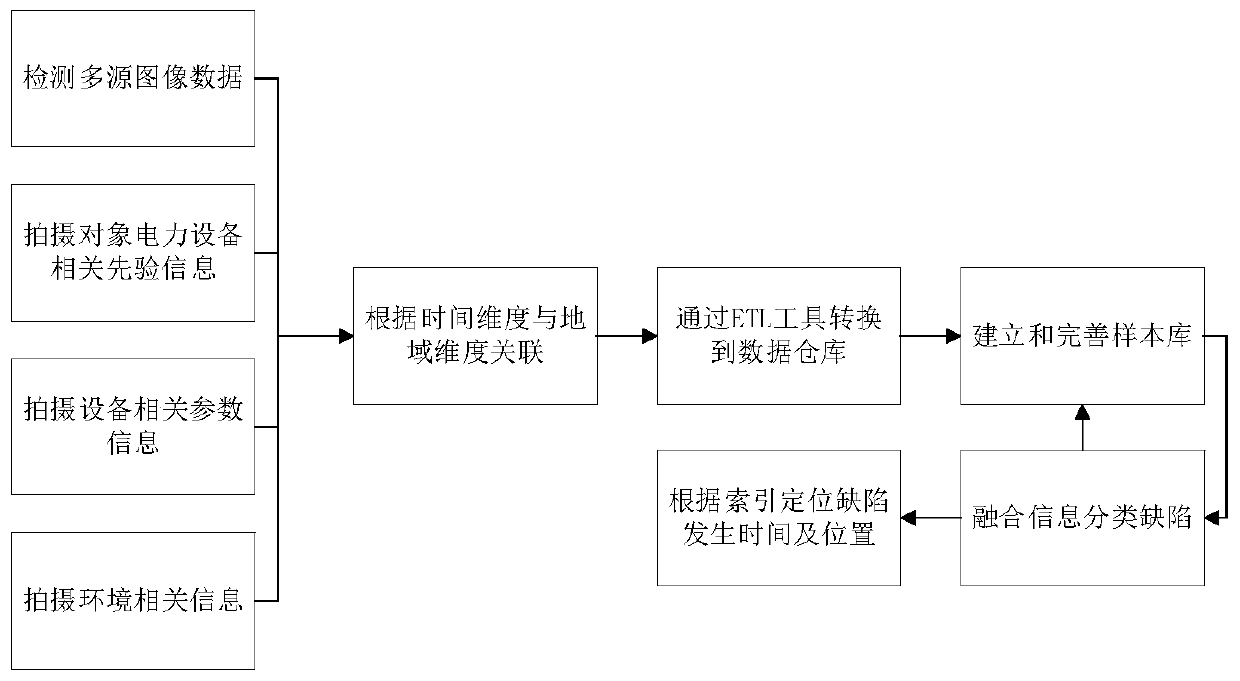

[0048] Such as figure 2 As shown, this embodiment provides a power equipment defect detection method based on the power equipment image data warehouse of Embodiment 1, including the following steps:

[0049] Constructing a sample library based on historical data in the data warehouse;

[0050] Training a support vector machine for defect detection based on the sample library;

[0051] Obtain the image features of the power equipment to be tested, integrate the environmental information features, and detect the information features through the trained support vector machine for detection and classification;

[0052] According to the detection results, the time and location of equipment defects are located through the index.

[0053] In another embodiment, the method further includes: storing the classified images into a data warehouse to complete the database.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com