Railway wagon brake beam strut round pin loss fault identification method

A technology for fault identification and railway wagons, which is applied in the field of image processing, can solve the problems of high cost of manual detection and low accuracy of machine detection, and achieve the effects of improving detection accuracy, reducing staff and increasing efficiency, and saving labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

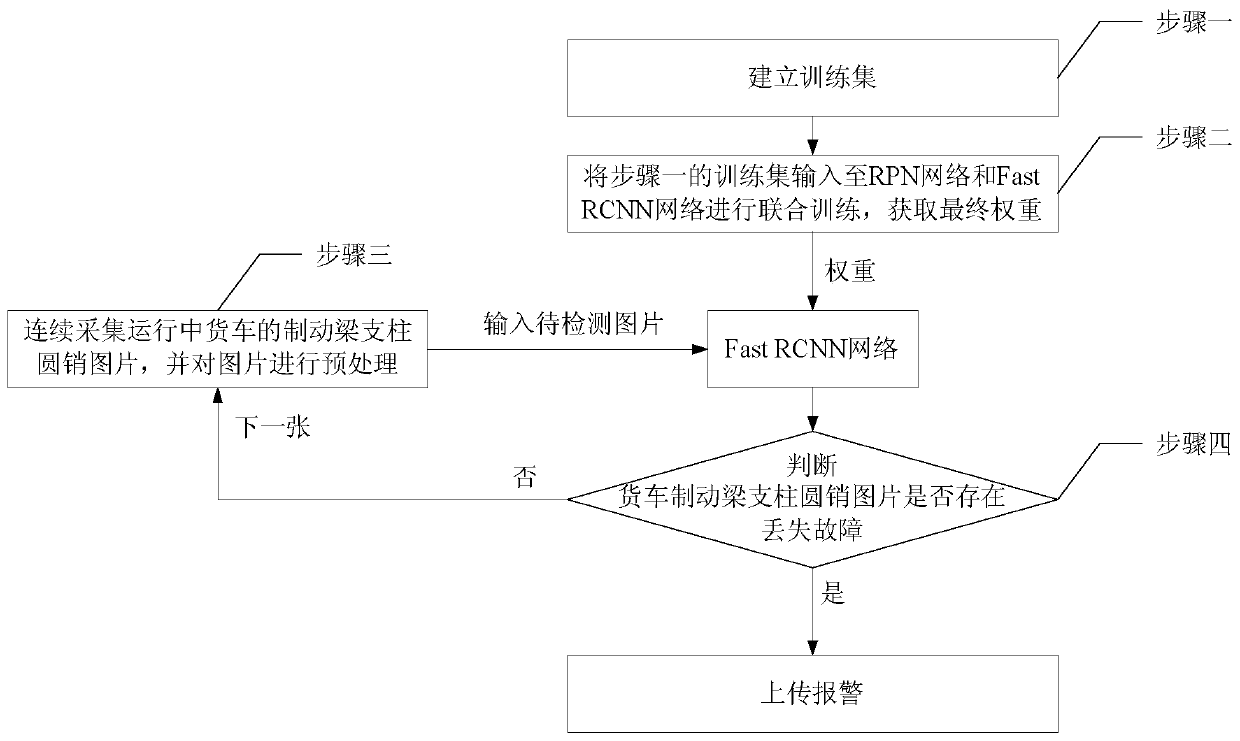

[0032] Specific implementation mode one, the following combination figure 1 This embodiment is described. The fault identification method for the loss of the round pin of the railway freight car brake beam pillar according to the embodiment is characterized in that the method includes the following steps:

[0033] Step 1. Collect the sample images of the round pins of the truck brake beam pillars to establish a training set;

[0034] 1. Collect samples

[0035] Capture sharp grayscale images with a high-resolution line scan camera. The principles for collecting images are as follows:

[0036] (1) Collect images of truck brake beam stations under various conditions such as rainwater, ice and snow, chalk graffiti, load leakage, mud stains, oil stains, black paint, and dust.

[0037] (2) Collect images of truck brake beam stations at different sites, different equipment, and at different times (different degrees of sunlight interference).

[0038] 2. Sample amplification

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com