Auxiliary device for chalcedony string and knotting

A kind of auxiliary equipment, chalcedony technology, applied in the application, clothing, jewelry and other directions, can solve the problem of not being able to put away the excess chalcedony, and achieve the effect of improving work efficiency and ensuring safe operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

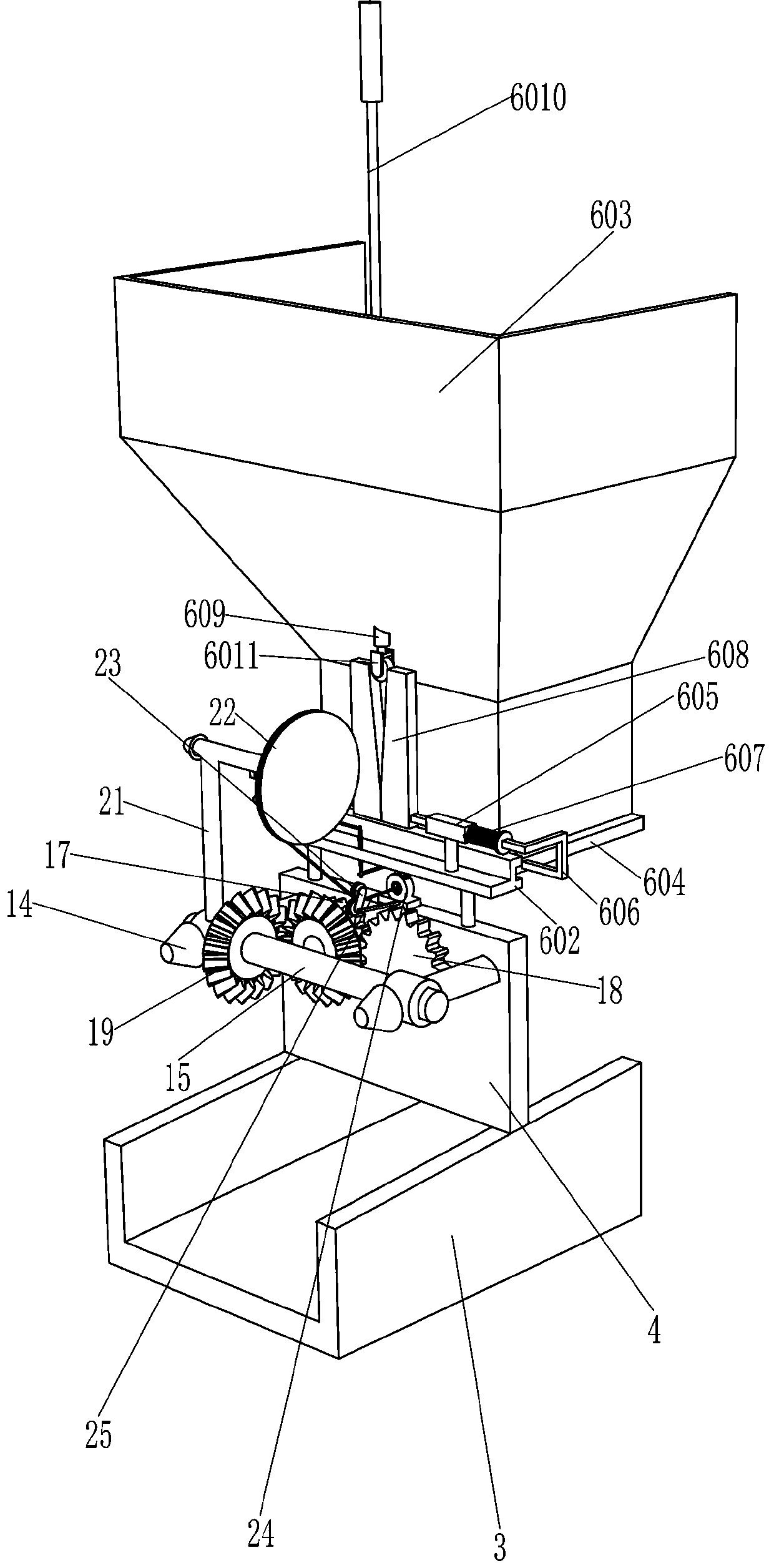

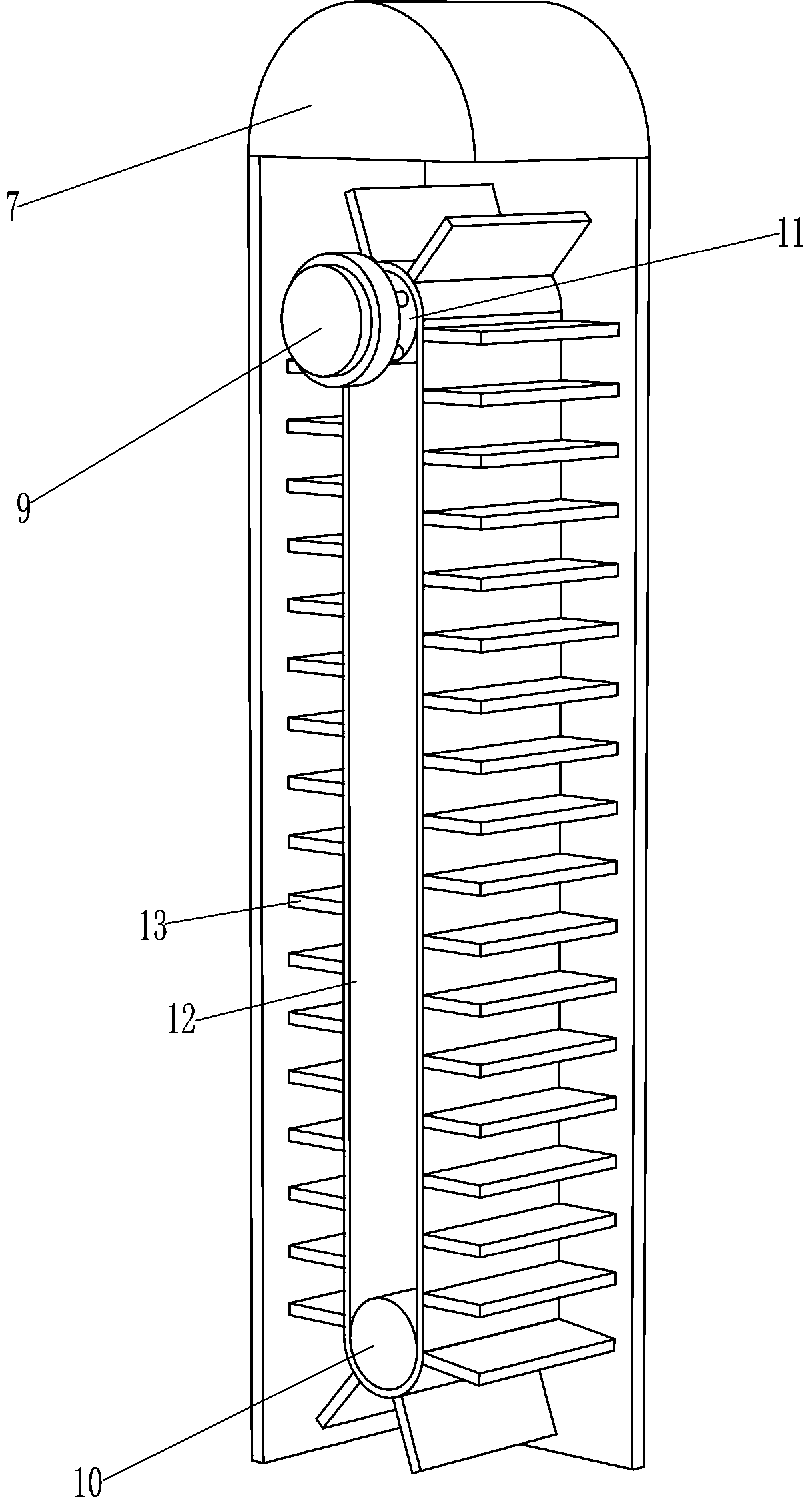

[0022] An auxiliary device for chalcedony stringing, such as Figure 1-5 As shown, it includes a base 1, a support column 2, an inclined groove frame 3, a vertical plate 4, a support seat 5, a discharge device 6, a receiving frame 7, a return pipe 8, a driving motor 9, a short shaft transmission roller 10, Long axis transmission roller 11, transmission belt 12, pusher plate 13, bearing seat 14, rotating shaft 15, roller 16, small diameter gear 17, large diameter gear 18, bevel gear 19 and drive assembly 20, the top of base 1 is provided with support column 2, The top of the support column 2 is provided with an inclined-plane groove frame 3, and the inclined-plane groove frame 3 is provided with a riser 4 and a support seat 5 from left to right. There is a material receiving frame 7, the opening of the material receiving frame 7 is connected with the left end of the slope groove frame 3, the upper part of the material receiving frame 7 is provided with a return pipe 8, and one ...

Embodiment 2

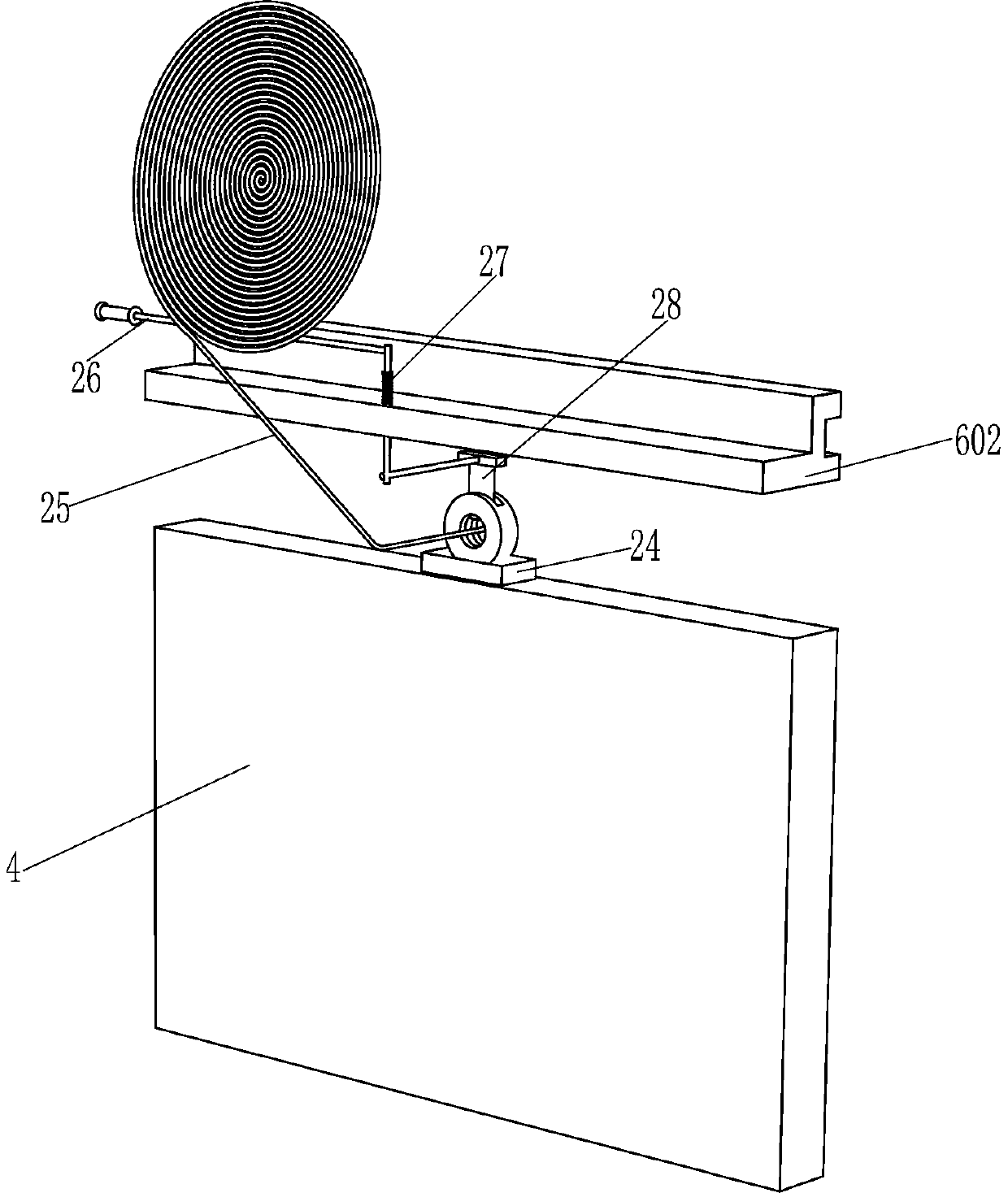

[0026] On the basis of Example 1, such as image 3 and Figure 5 Shown, also include support 21, winding reel 22, guide frame 23, ring sleeve 24 and thin wire 25, rear side bearing seat 14 is provided with support 21, is connected with reel 22 in rotation on the support 21, winds Thin wire 25 is wound on the wire reel 22, and the top of riser 4 is provided with ring sleeve 24, and guide frame 23 is arranged on ring sleeve 24, and the end of thin wire 25 goes around guide frame 23 and passes through ring sleeve 24.

[0027]A sufficient amount of thin wire 25 is wound on the reel 22. When the worker needs to use the thin wire 25, he can directly pull the thin wire 25, which avoids the phenomenon that the worker pulls the thin wire 25 from other equipment, and simplifies The operation steps of workers improve the work efficiency of workers.

[0028] Such as Figure 5 As shown, it also includes a sliding rod 26, a second compression spring 27 and a cutter 28. The second guide g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com