Analysis device, float glass manufacturing device, analysis method, and float glass manufacturing method

A technology for float glass and manufacturing equipment, which is applied in the field of analysis equipment, and can solve problems such as inability to meet plate thickness deviations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Hereinafter, specific embodiments of the analysis apparatus, float glass manufacturing apparatus, analysis method, and float glass manufacturing method of the present invention will be described in detail using the drawings.

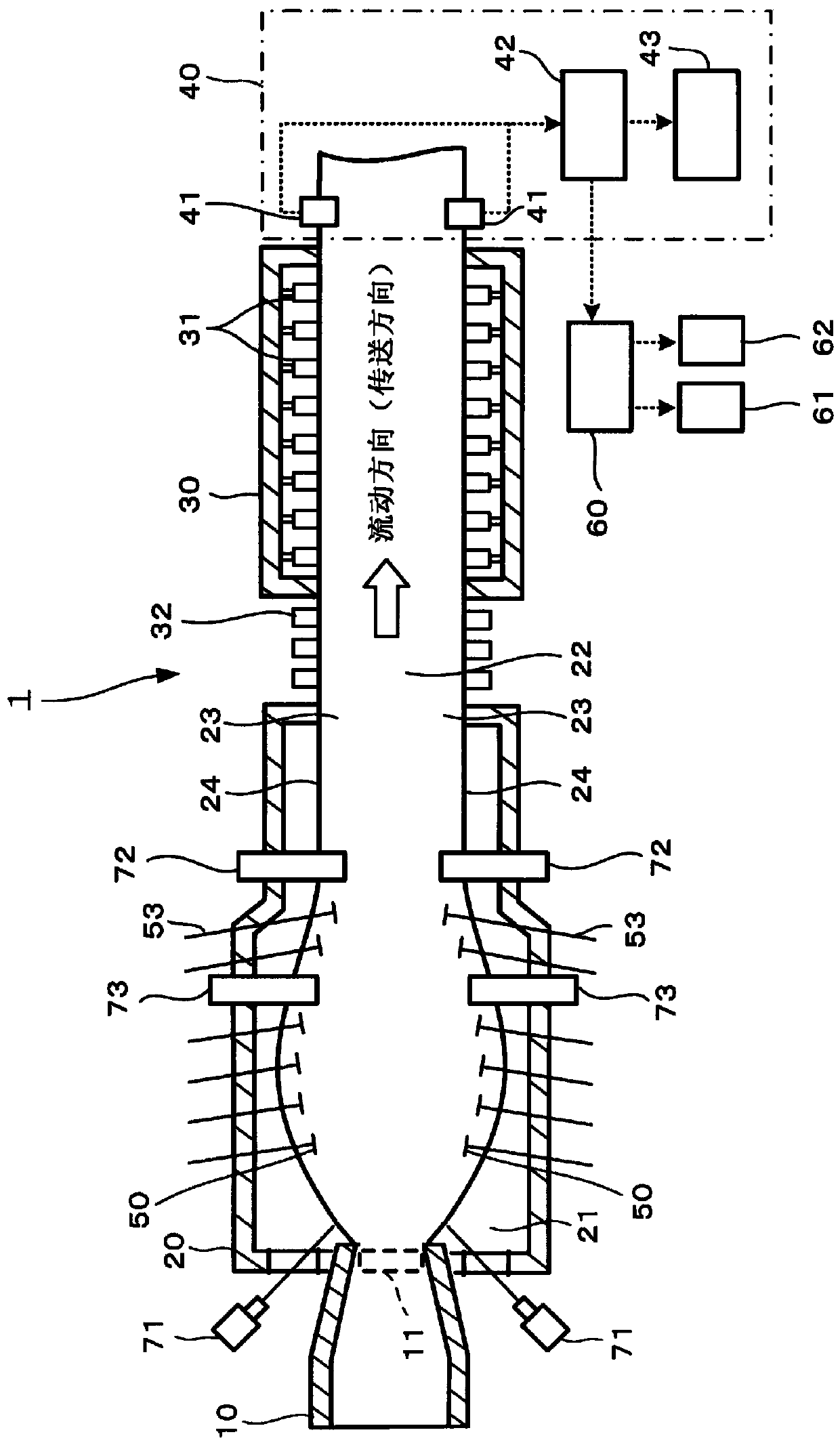

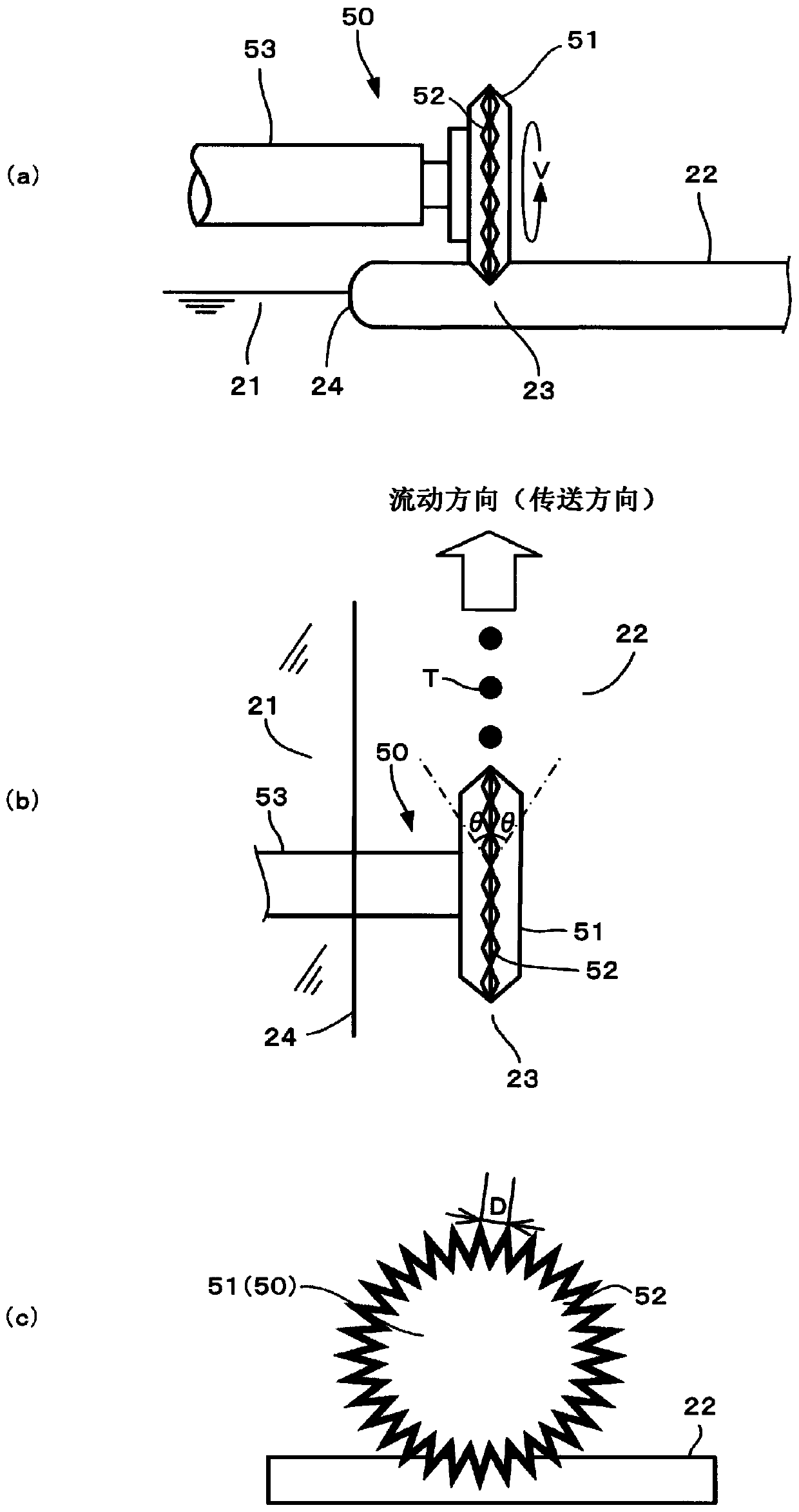

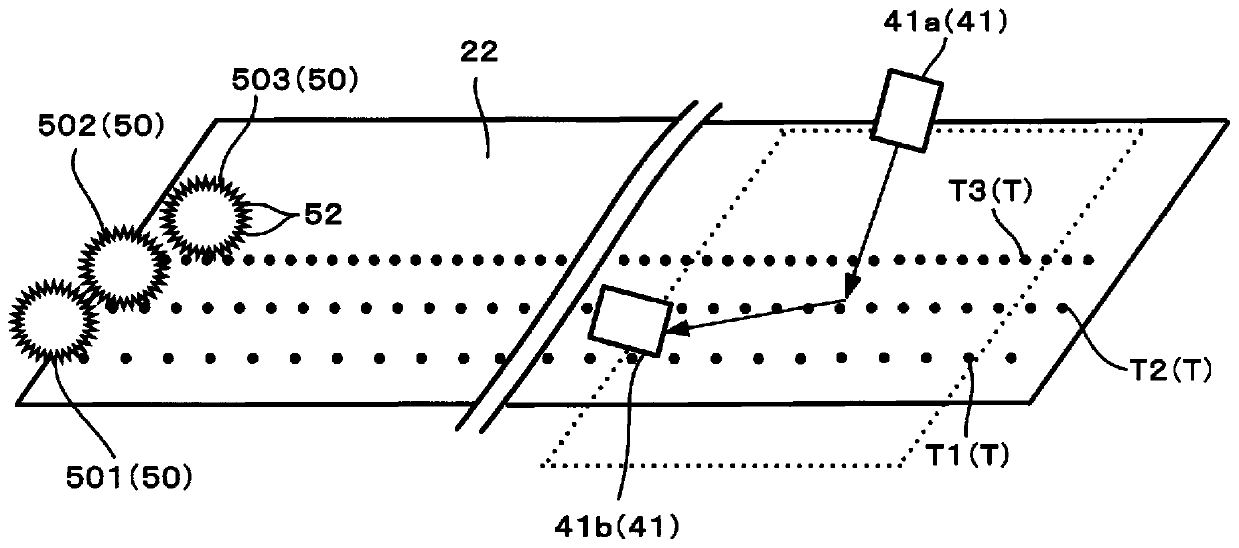

[0046] figure 1 It is a conceptual diagram which shows an example of the float glass manufacturing apparatus of this embodiment. figure 2 The relationship between the upper roll and the glass ribbon is shown, (a) is a conceptual diagram from the side, and (b) is a conceptual diagram viewed from the top. image 3 It is a conceptual diagram showing the upper roller and the recess. based on Figure 1 ~ Figure 3 , and the float glass manufacturing apparatus of this embodiment will be described.

[0047] The float glass manufacturing apparatus 1 of this embodiment is equipped with the melting furnace 10, the molten metal tank 20, the slow cooling furnace 30, and the analysis apparatus 40. In the molten metal tank 20 , a plurality of pairs of upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com