ethod for constructing cutting geometric model based on Solidworks

A technology of geometric model and construction method, which is applied in the field of tooth cutting and can solve problems such as no engineering application cases.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0077] The following is further described in detail through specific implementation methods:

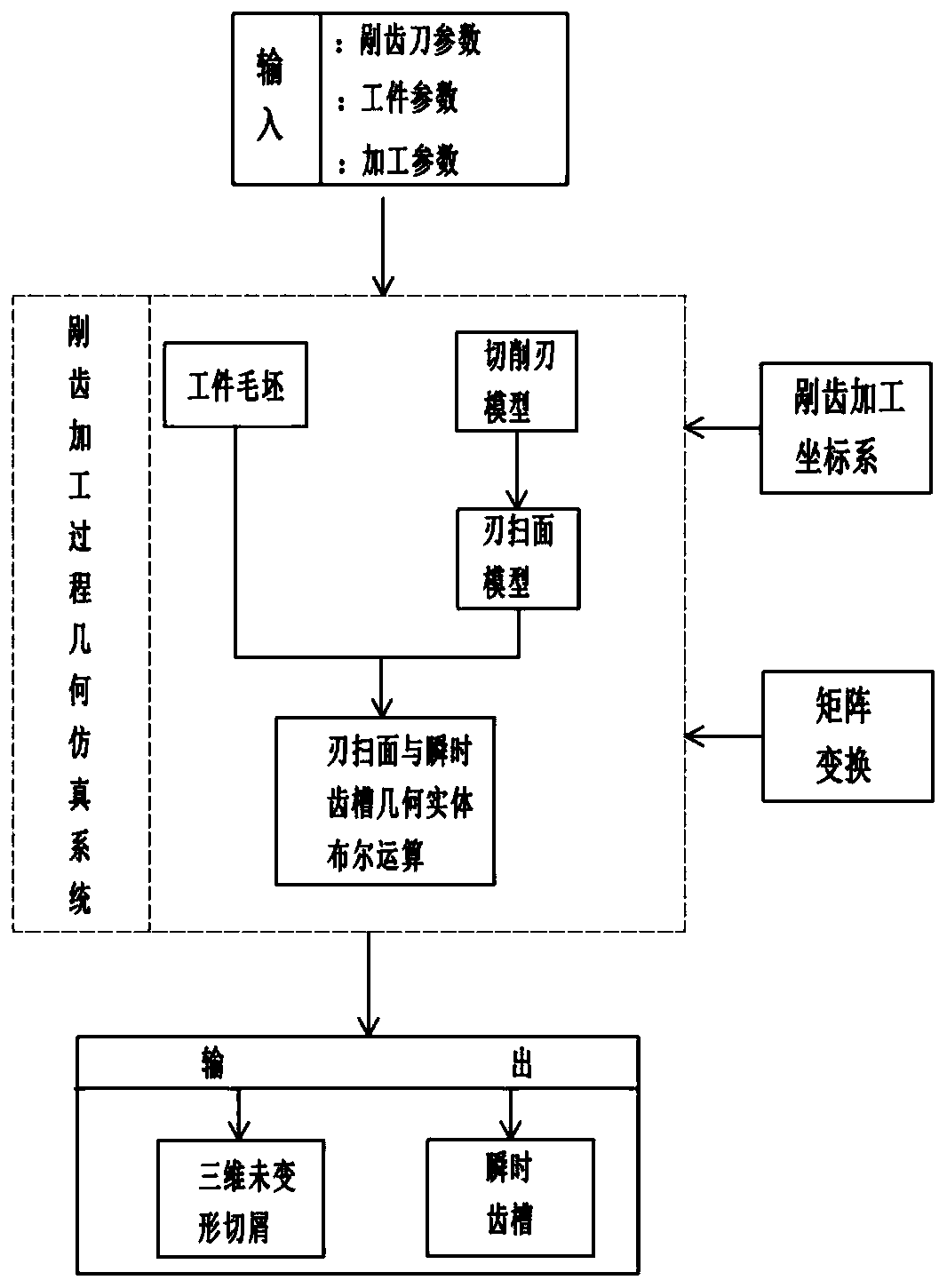

[0078] The embodiment is basically as attached figure 1 Shown: The method of building the cutting chip geometry model based on Solidworks includes parameter input, cutting edge model establishment, edge sweep surface model establishment, instantaneous cogging generation and output.

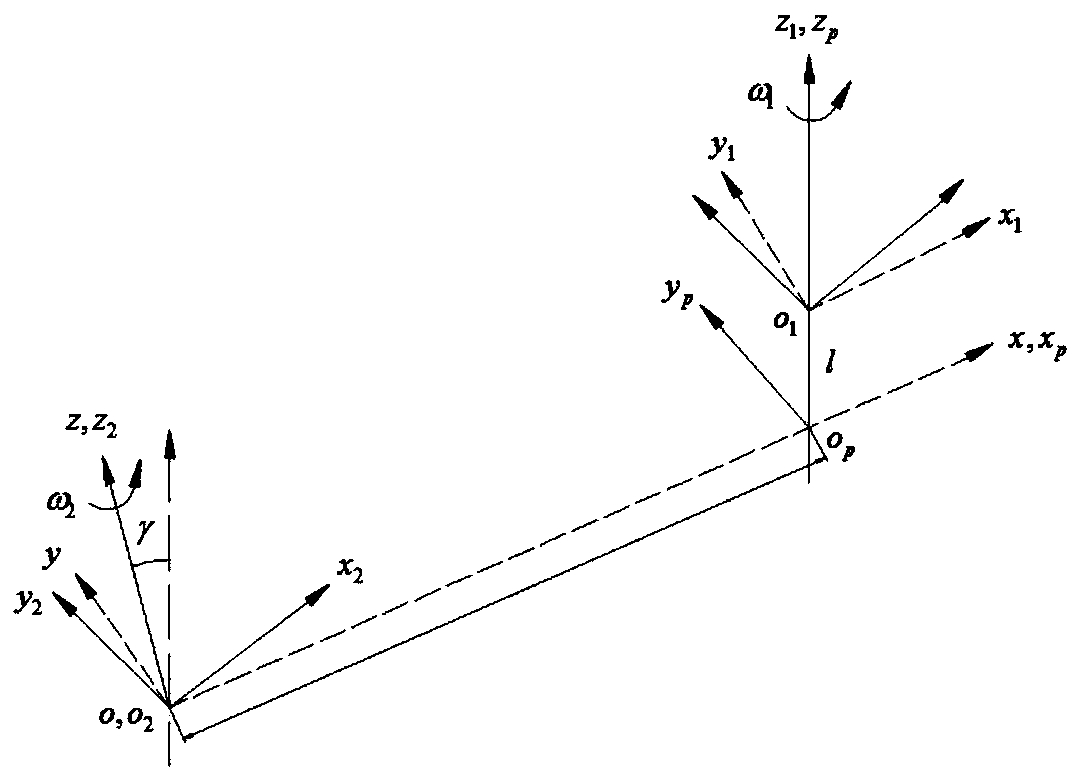

[0079] Please refer to figure 2 , where the parameters are input as follows, first establish the coordinate system: the workpiece coordinate system is S 1 (o 1 ,x 1 ,y 1 ,z 1 ), where o 1 means S 1 Coordinate origin of the coordinate system, x 1 axis, y 1 axis, z 1 The unit vectors of the axes are respectively i 1 , j 1 ,k 1 ;S p (o p ,x p , y p ,z p ) is S 1 (o 1 ,x 1 ,y 1 ,z 1 ), where o p means S p Coordinate origin of the coordinate system, x p axis, y p axis, z p The unit vectors of the axes are respectively i p , j p ,k p .

[0080] The tool coordinate system is S ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com