Asynchronous motor self-adaptive vector control system with stator temperature online monitoring function

A technology of asynchronous motor and stator temperature, applied in vector control system, electronic commutation motor control, control system, etc., can solve the problem of increasing the complexity of the control system, increasing the cost and source of failure, stability, reliability, rapidity and Negative effects of accuracy and other issues, to achieve the effect of simple and efficient control strategy, simple and accurate calculation and closed-loop control, and improve speed and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

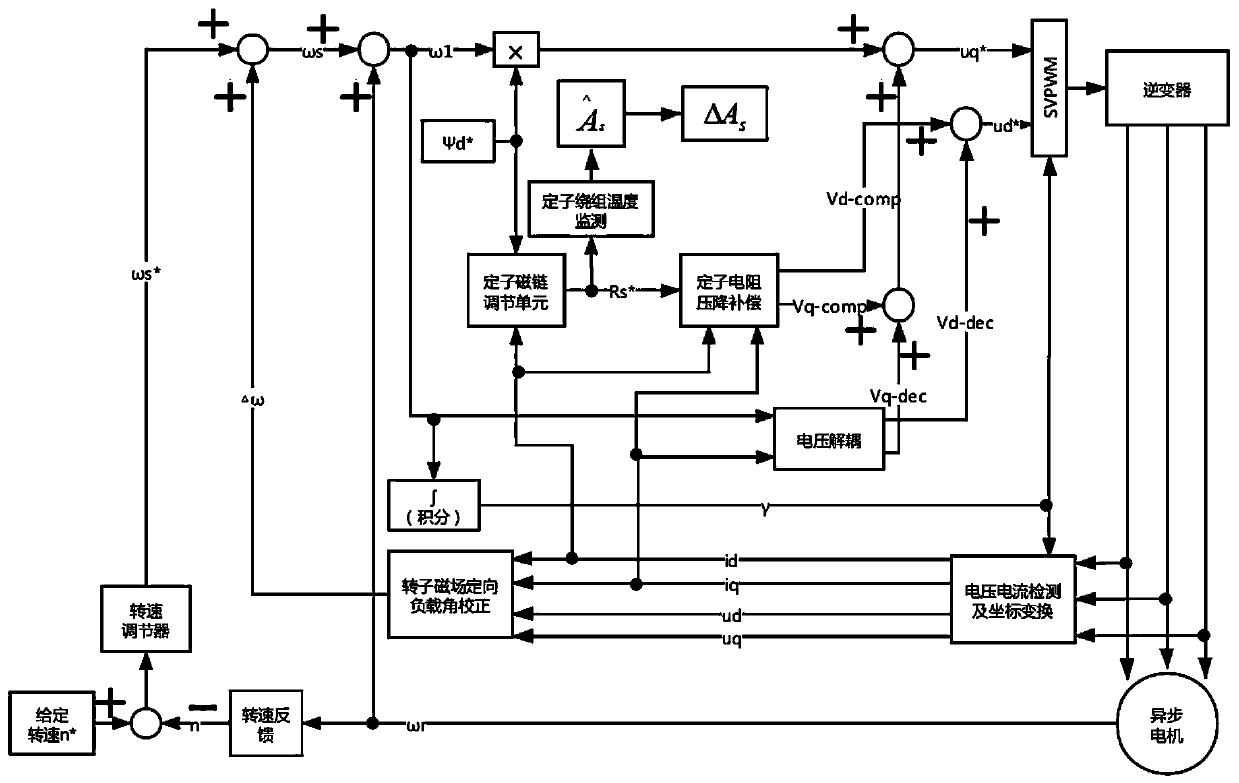

[0057] The invention relates to an asynchronous motor self-adaptive vector control system with stator temperature online monitoring, the system includes:

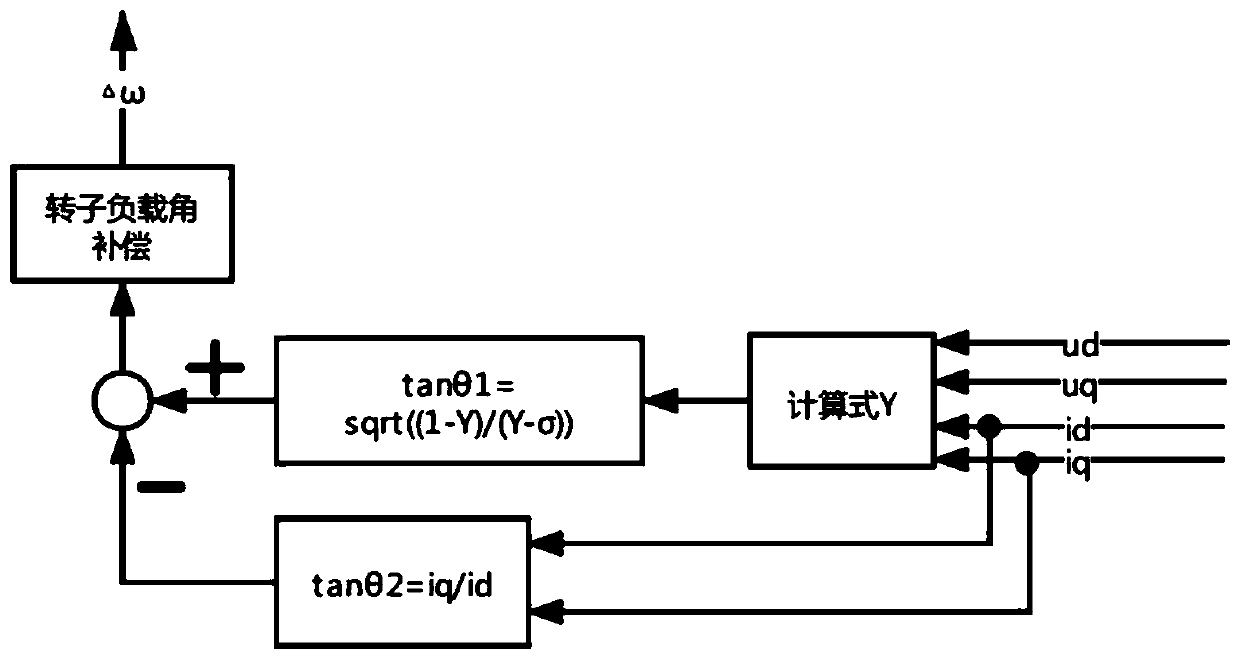

[0058] The rotor magnetic field accurate orientation module is used to accurately orient the rotor magnetic field based on the load angle compensation correction according to the current and voltage signals in the d-q synchronous rotation coordinates.

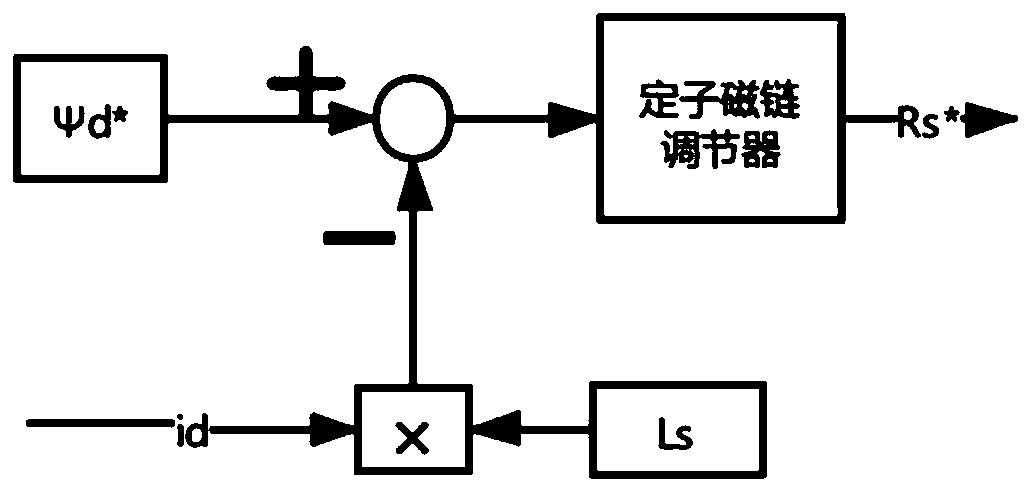

[0059] The stator flux linkage adjustment module is used for closed-loop control of the stator d-axis flux linkage and correction of the stator resistance identification.

[0060] The stator voltage decoupling module is used to decouple the d-axis voltage and q-axis voltage according to the closed-loop control results of the accurate orientation of the rotor magnetic field and the stator d-axis flux linkage.

[0061] The stator resistance voltage drop compensation module is used to compensate the stator resistance voltage drop according to the output result of the stator flu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com