Yarn carrying guide piece, yarn laying device for three-dimensional fabric and yarn laying mode

A guide sheet and yarn laying technology, which is applied in the direction of textile, loom, textile and papermaking, etc., can solve the problems affecting the weaving speed and efficiency, the quality of three-dimensional fabrics, and the quality of fibers, so as to improve quality, reduce damage, and improve efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

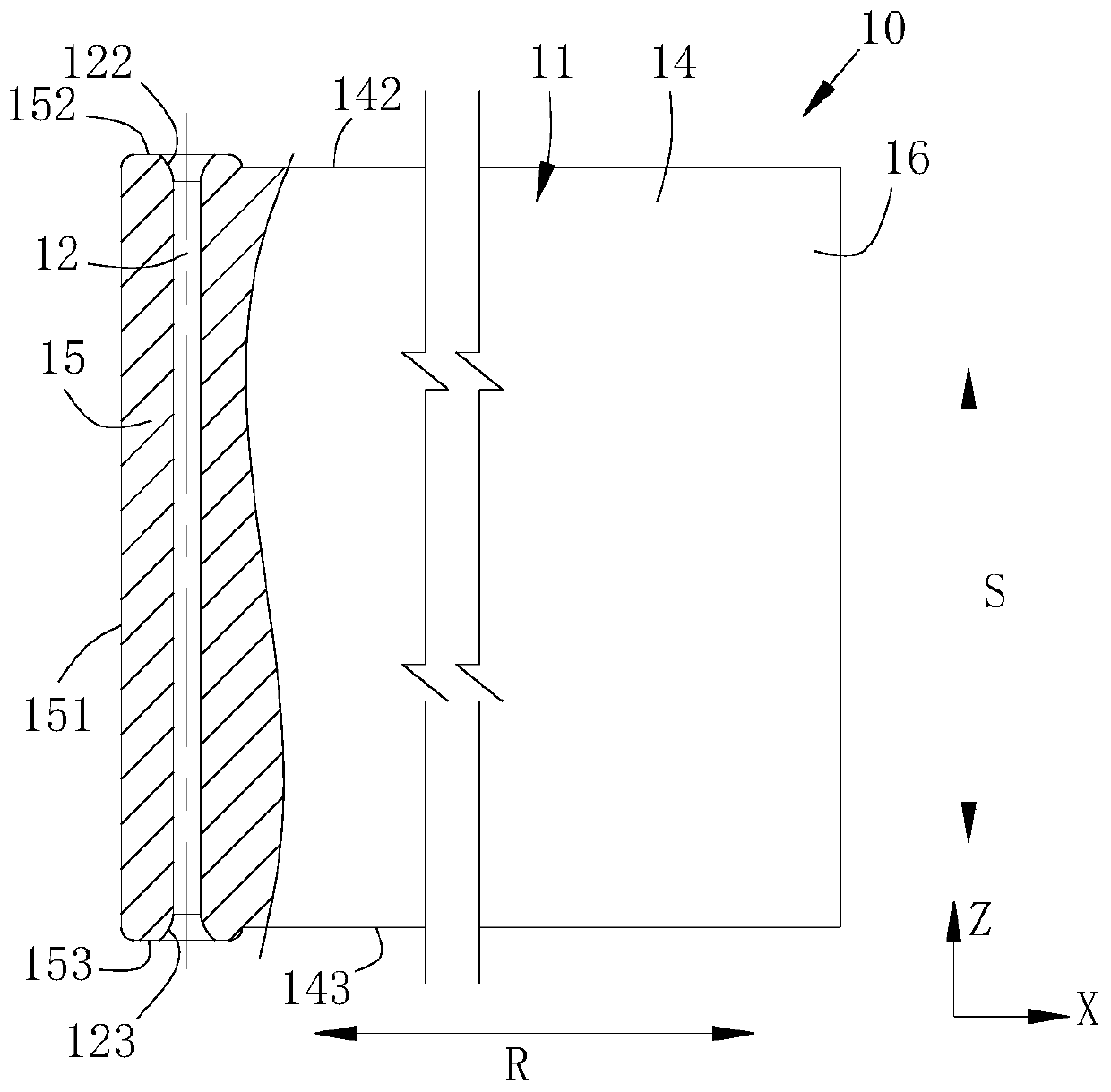

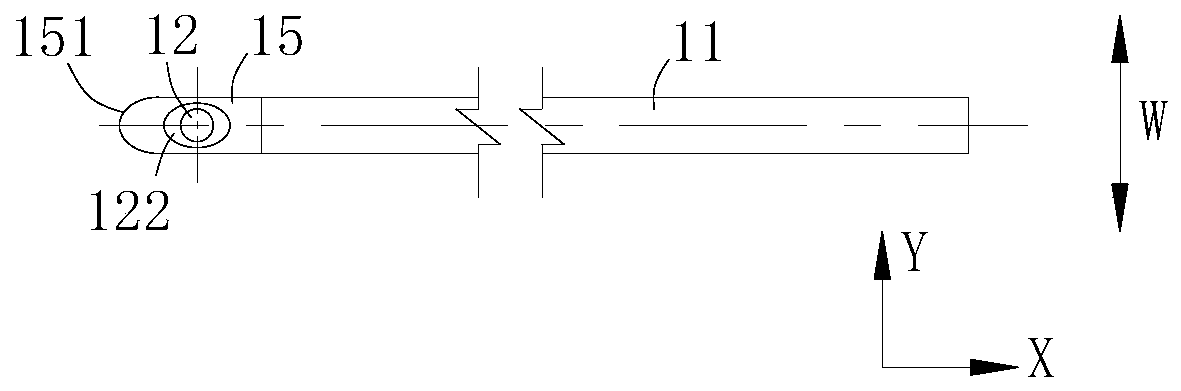

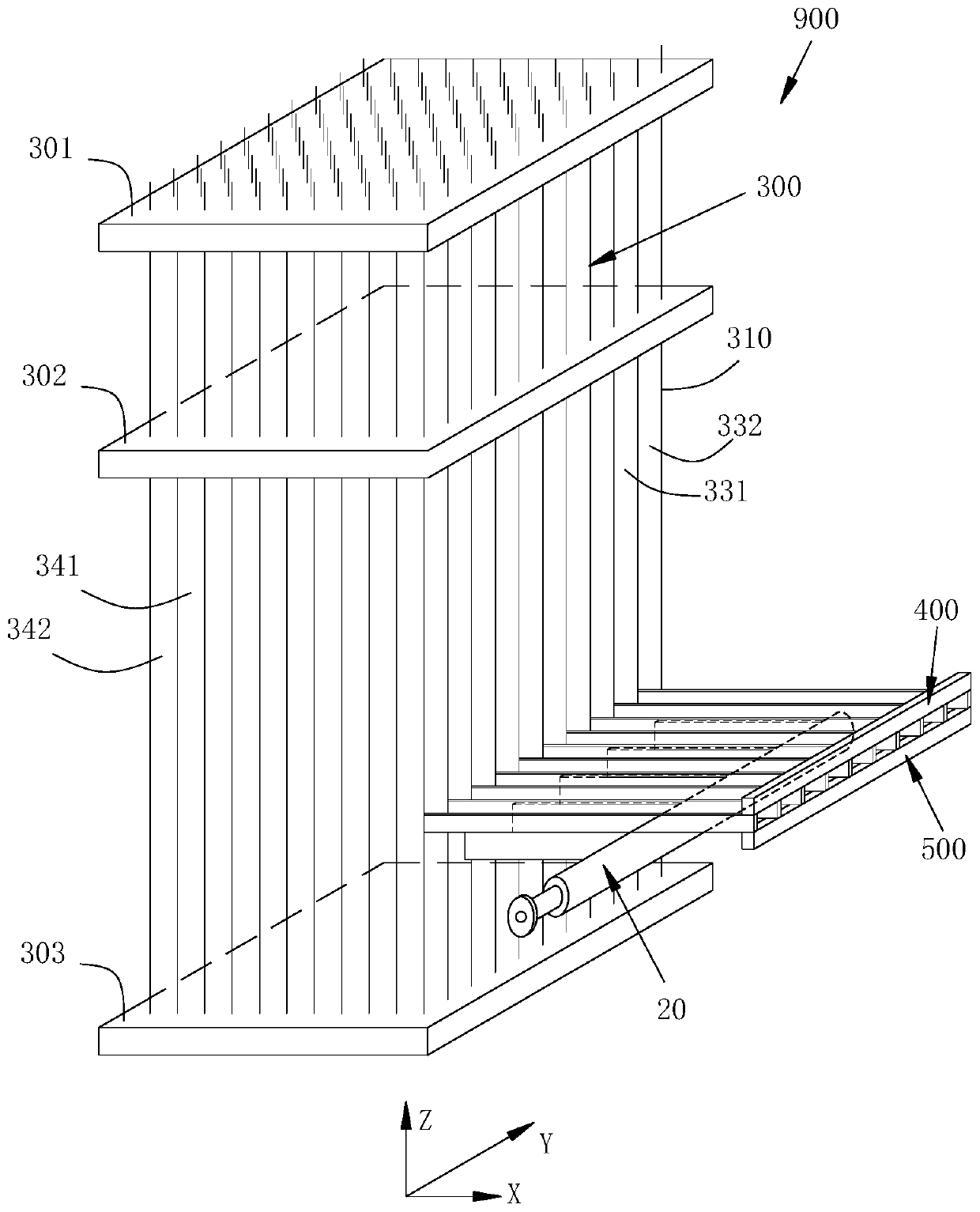

[0070] First, the yarn-carrying guide piece 10 is described, please refer to figure 1 with figure 2The yarn-carrying guide plate 10 includes a strip-shaped guide plate 11, the middle part of the guide plate 11 is formed as a plate body 14, and the two ends of the length direction of the guide plate 11 are respectively formed as a yarn-carrying end 15 and a fixed end. 16. A yarn-drawing hole 12 is provided at the yarn-carrying end 15, and the yarn-drawing hole 12 extends along the width direction S of the guide plate and runs through both sides of the yarn-carrying end in the width direction.

[0071] exist figure 1 with figure 2 Among them, the direction of the arrow marked R indicates the length direction of the guide plate, that is, the length direction of the yarn-carrying guide piece; the direction of the arrow marked S indicates the width direction of the guide plate, that is, the width direction of the yarn-carrying guide piece; The direction of the arrow marked W i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com