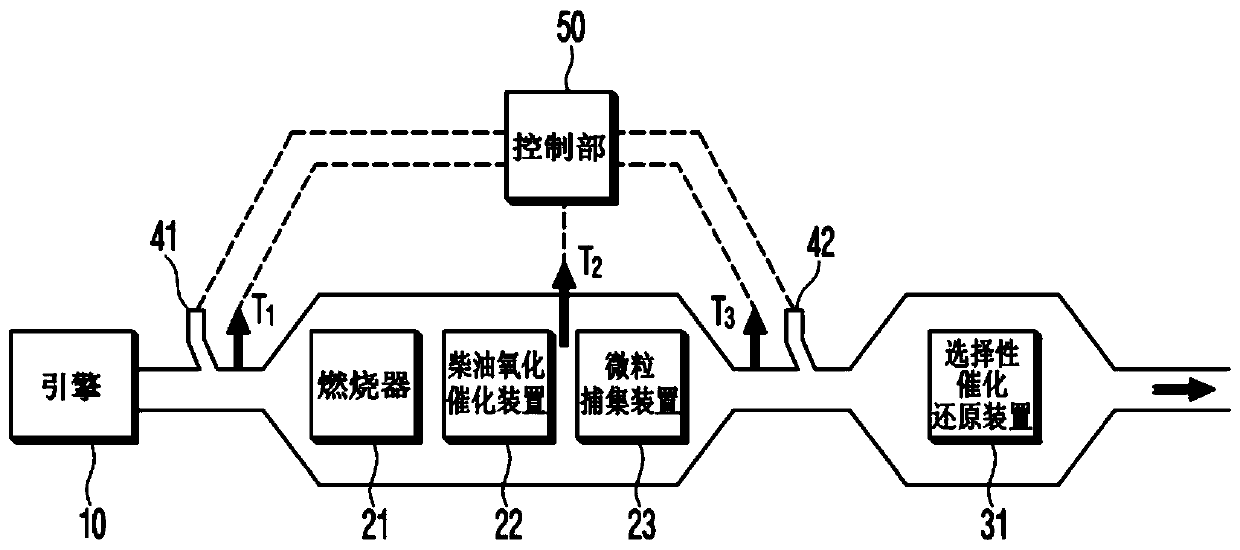

System for after-treatment of exhaust gas and method for controlling of the same

A technology for exhaust after-treatment and control, which is applied to the electronic control of exhaust treatment devices, exhaust treatment, exhaust devices, etc., and can solve the problems of complicated burner size and structure, larger flame, and more fuel injection. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

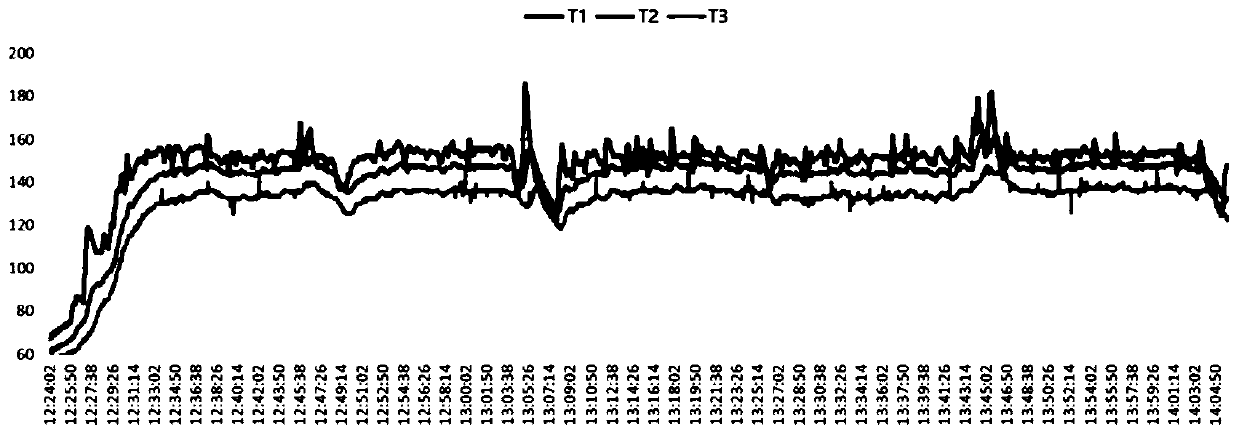

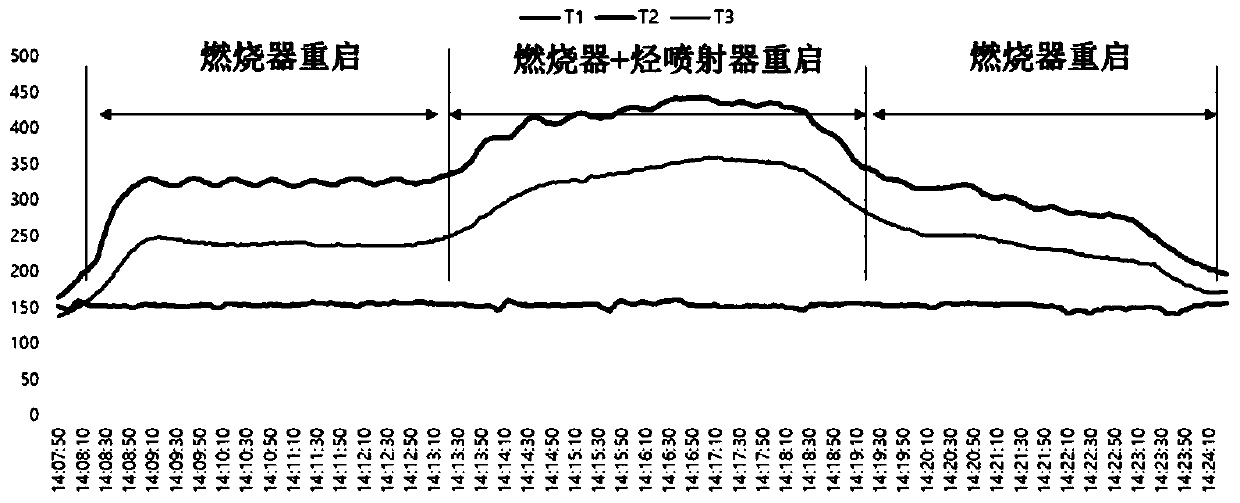

[0034] Hereinafter, the embodiments disclosed in this specification will be described in detail with reference to the drawings, and the same reference numerals will be assigned to the same or similar constituent elements regardless of the reference numerals, and repeated description thereof will be omitted. The suffixes "module" and "part" of the structural elements used in the following description are given or mixed in consideration of the simplicity of formulation of the description, and do not have mutually distinguishing meanings or functions. In addition, in describing the embodiments disclosed in this specification, if it is judged that the detailed description of related known technologies makes the gist of the embodiments disclosed in this specification unclear, the detailed description will be omitted. Moreover, the accompanying drawings are only used to easily understand the embodiments disclosed in this specification, and the technical ideas disclosed in this specif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com