Cam loading type tapered roller bearing testing machine

A tapered roller bearing and testing machine technology, which is applied in the direction of mechanical bearing testing, etc., can solve problems such as poor data traceability, unstable force, and poor consistency of test results, so as to increase accuracy and repeatability and ensure accuracy and repeatability, the effect of simplifying the human operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

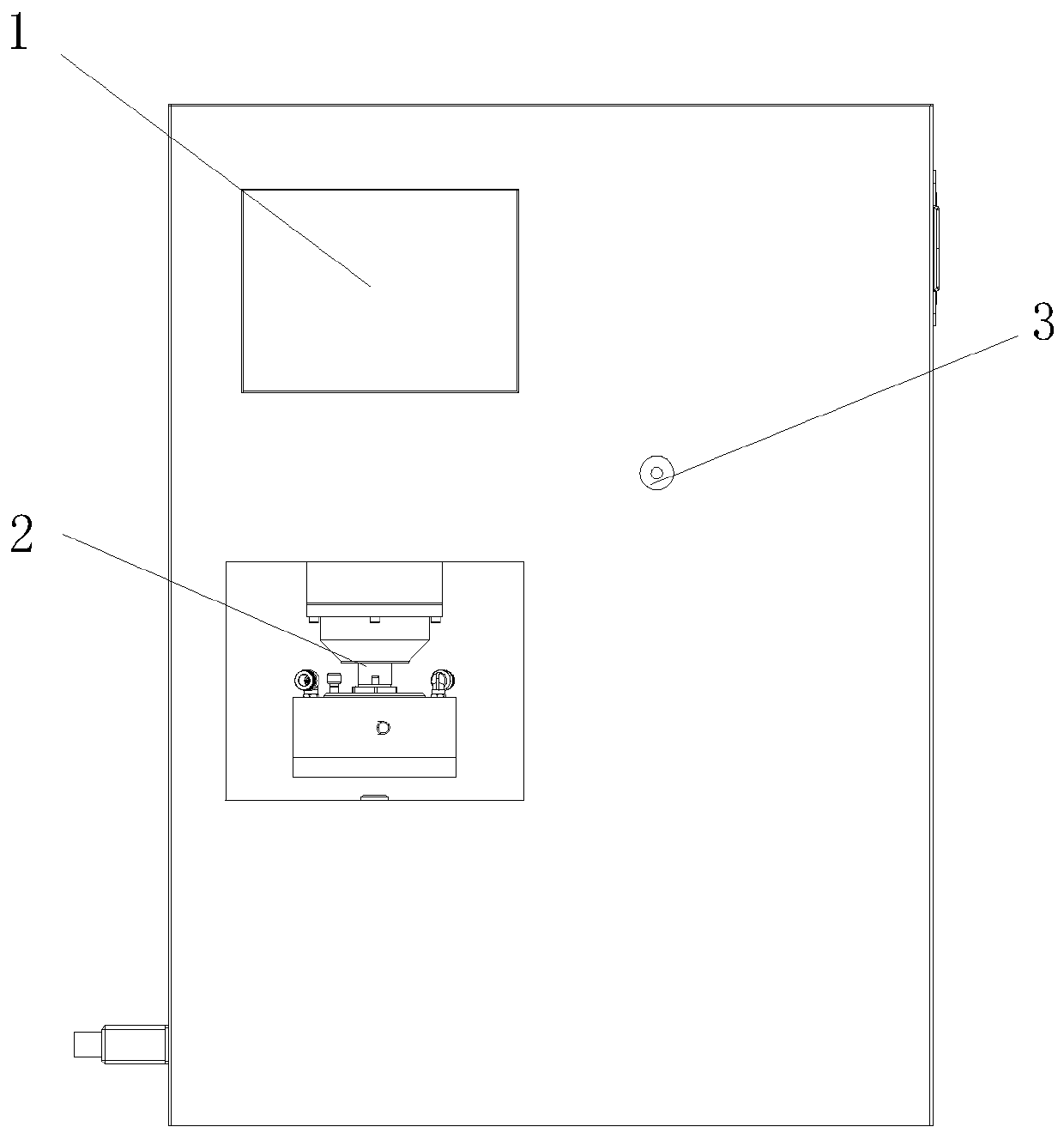

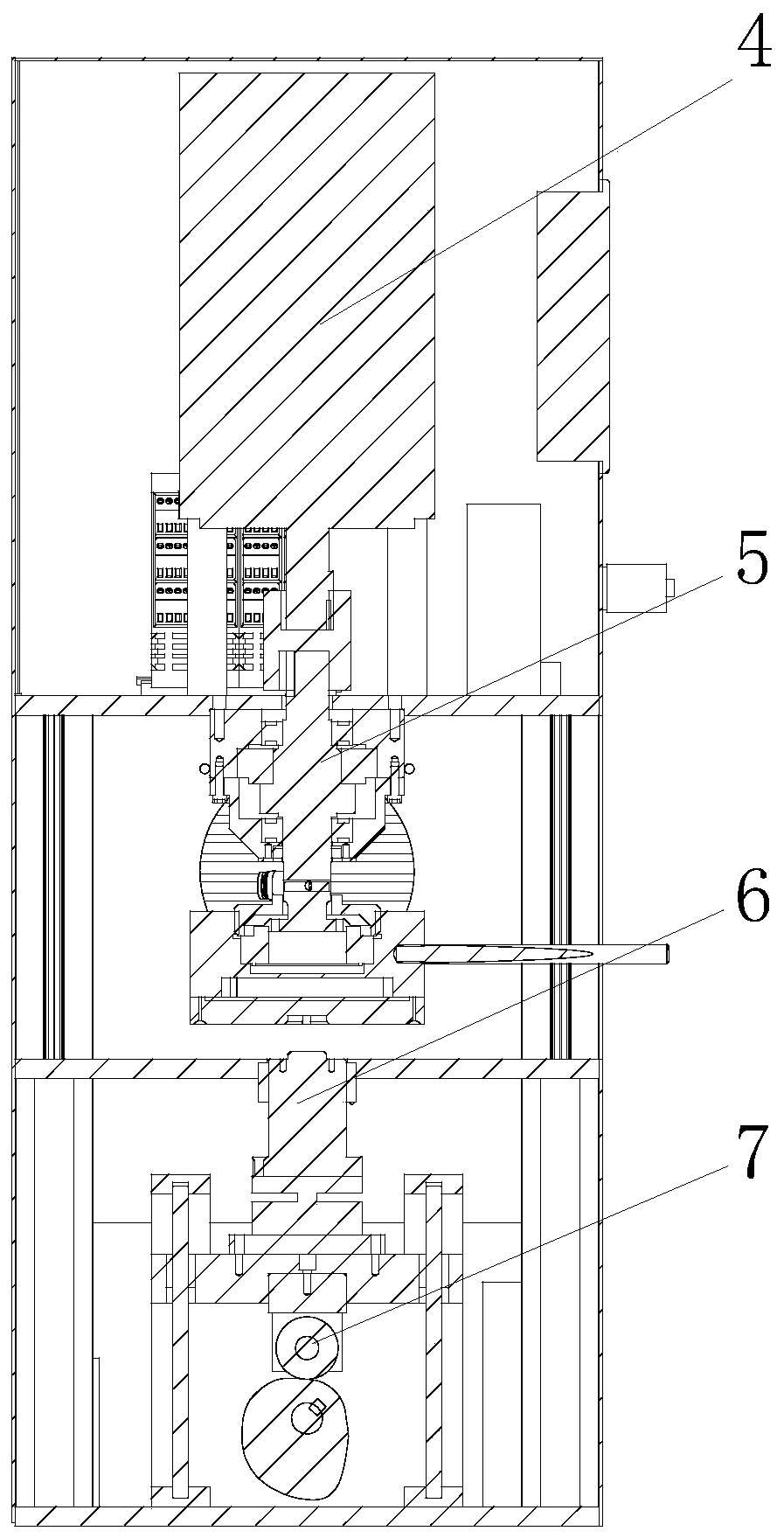

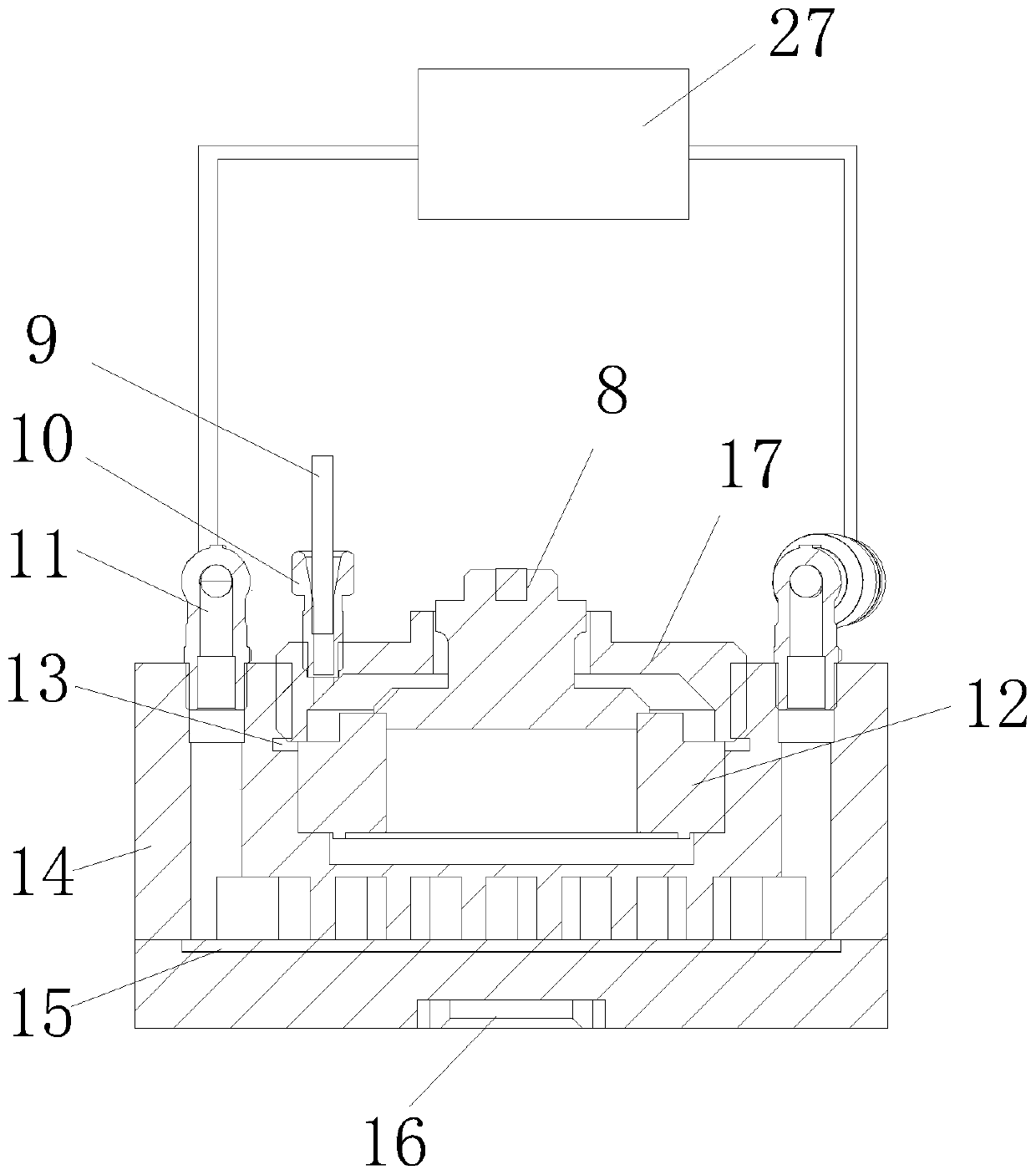

[0045] KRL adapter 6, main engine, constant temperature water bath 27; KRL adapter 6 has a built-in tapered roller bearing 12, the lubricating oil to be tested is loaded at the inner ring position of the tapered roller bearing 12 and infiltrated the bearing, and the sealing ring 13 is compressed by using the upper screw cap 17 and the outer ring of the tapered roller bearing 12 to ensure that the lubricating oil to be tested is fully sealed and does not leak, and at the same time ensures that when the tapered roller bearing 12 rotates, the fixed part of the bearing outer ring does not slide, ensuring that the lubricating oil to be tested is fully sheared; There is a through hole at the flat end of the rotating spindle 8 to ensure that when the tapered roller bearing 12 is rotated to realize the shearing of the lubricating oil to be tested, the lubricating oil to be tested can be fully circulated through the through hole to ensure that all the lubricating oil to be tested is comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com