Method for testing the anti-tarnish protection effect of high temperature resistant coating on stainless steel surface

A technology with protective effect and high temperature resistance, which is applied in the direction of measuring devices, weather resistance/light resistance/corrosion resistance, instruments, etc., to achieve the effect of ensuring stability, convincing power, and accurate and reliable test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

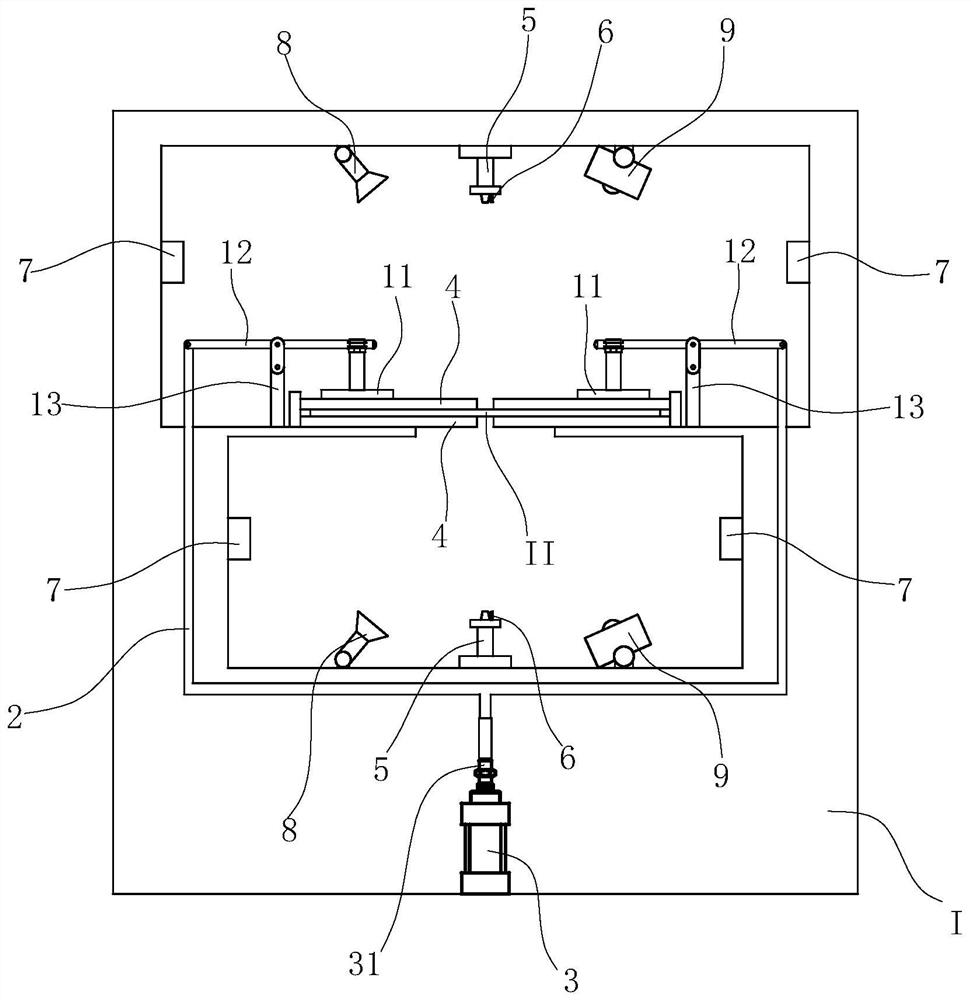

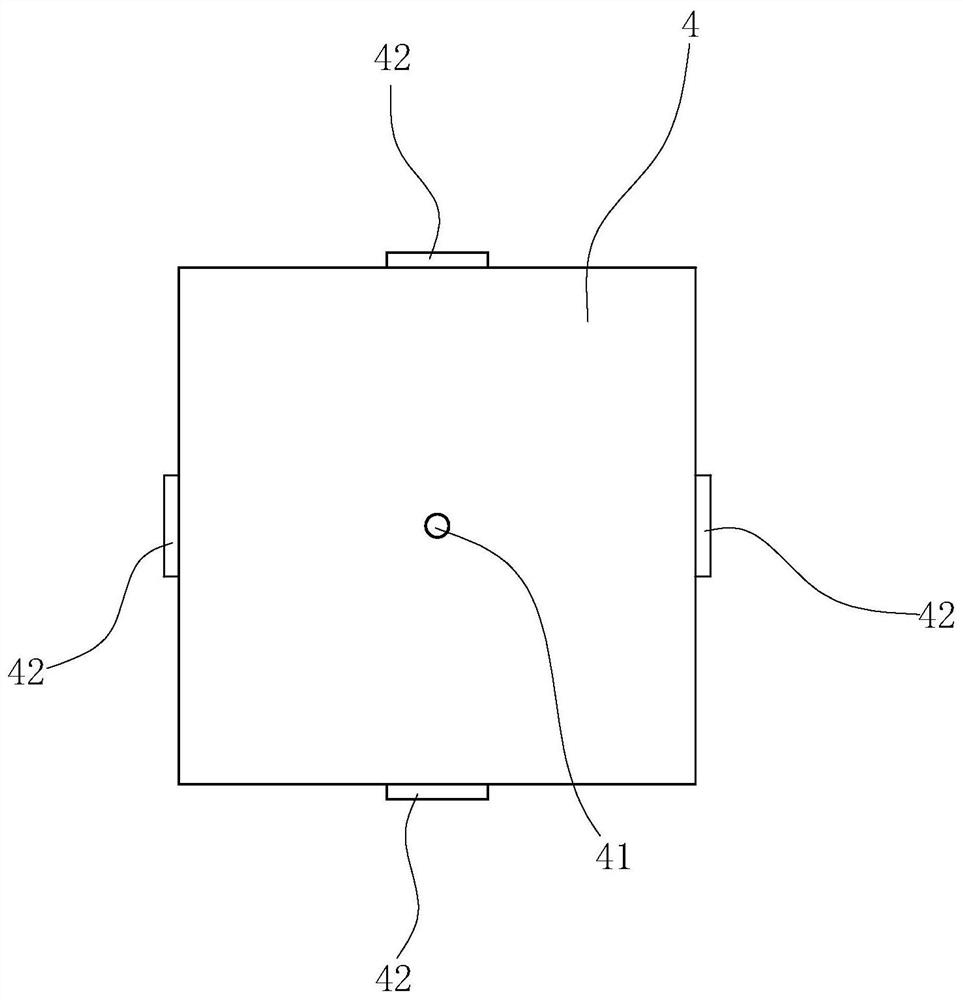

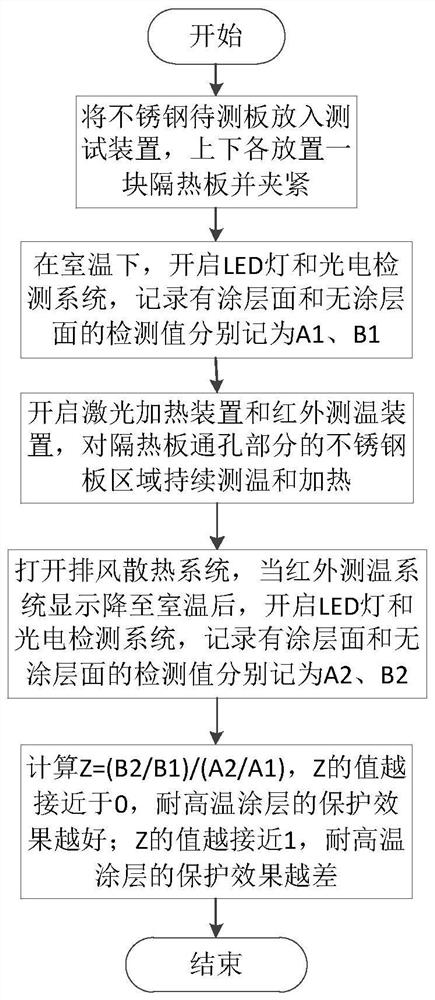

[0042] Such as figure 1 , figure 2 As shown, this embodiment discloses a device for testing the anti-tarnish protection effect of a high-temperature resistant coating on a stainless steel surface. The device includes a chamber 1, which is provided with a clamping mechanism, a transmission mechanism, a heating Device 5, temperature measuring probe 6, exhaust air cooling system 7, light source 8, photoelectric detection probe 9 and photoelectric detection circuit.

[0043] Among them, the clamping mechanism is arranged in the middle position of the chamber I, and is used for clamping and fixing the stainless steel plate S to be tested. In order to facilitate the clamping of the stainless steel plate to be tested, the clamping mechanism includes at least two symmetrically arranged opening and closing The jaw 11 and the swing arm 12 that drives...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com