Optical signal collecting device and etching equipment

A technology for collecting devices and optical signals, which is applied to discharge tubes, electrical components, circuits, etc., and can solve the problems of many steps and long time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

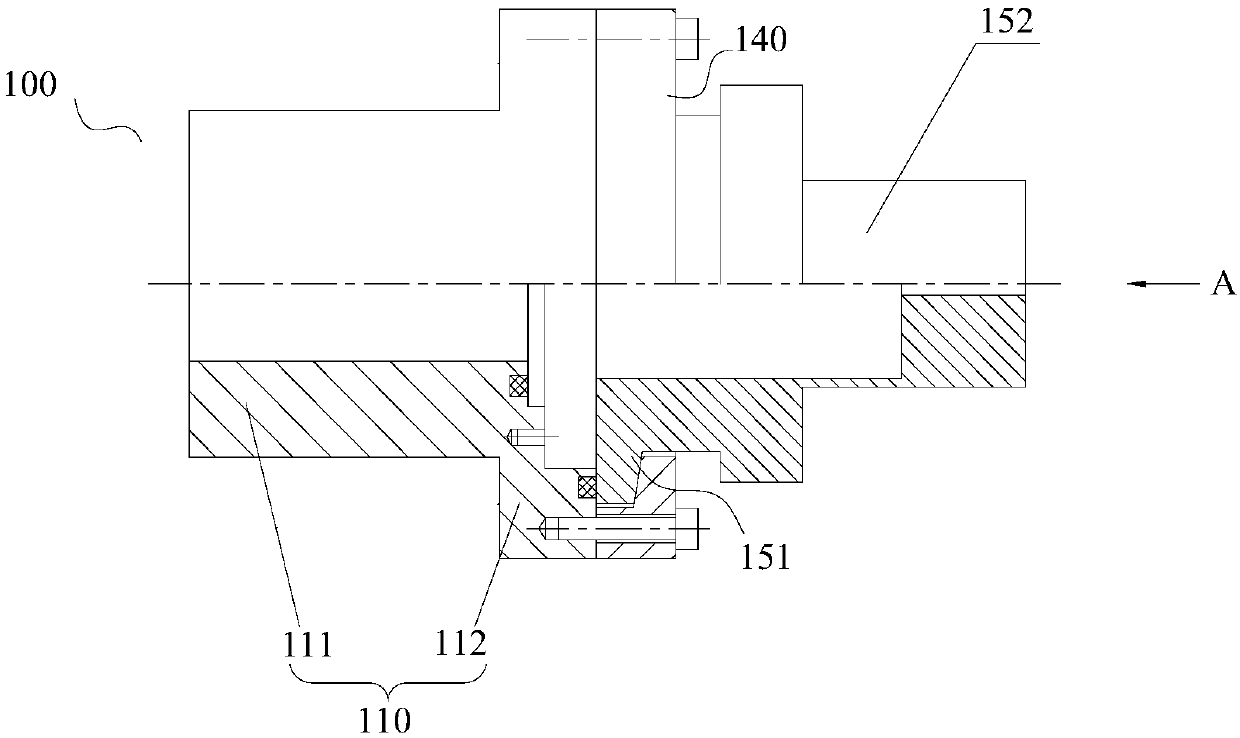

[0083] As a preferred embodiment of the present invention, when the installation sleeve 110 includes the installation cylinder portion 111 and the second fixing flange 112, the installation cylinder portion 111 of the installation sleeve 110 is arranged in the second installation hole 211, and the installation sleeve The second fixing flange 112 of 110 is detachably fixedly connected to the outside of the wall 210 of the etching chamber.

[0084] In order to prevent foreign matter from entering the etching chamber, further preferably, a seal is formed between the second fixing flange 112 and the outer surface of the wall 210 of the etching chamber. The forms of sealing include but are not limited to sealing rings, gaskets, and oil seals.

[0085]Compared with the scheme in the prior art where the cylindrical mounting sleeve is fully inserted into the second mounting hole 211 and a sealing ring is provided between the mounting sleeve and the second mounting hole 211, the mounti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com