A method for stirring positive electrode slurry

A technology of positive electrode slurry and positive electrode active material, which is applied in chemical instruments and methods, electrode manufacturing, battery electrodes, etc., can solve the problems of sedimentation and positive electrode active material sedimentation, and achieve the effect of avoiding sedimentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

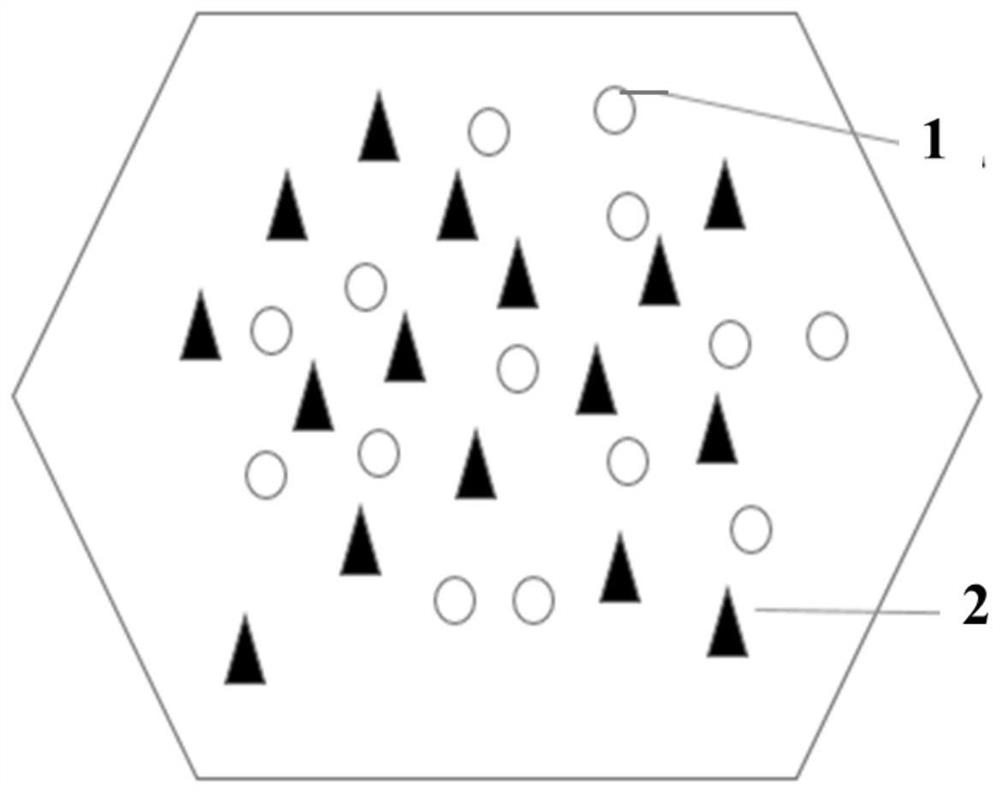

Image

Examples

Embodiment 1

[0040] A method for stirring positive electrode slurry:

[0041] The positive electrode slurry (the positive electrode slurry is made up of N-methylpyrrolidone, NCM532 and graphite, and the mass ratio of NCM532 and graphite is 9:1) is added respectively in 5 reaction chambers and carried out stirring process, each reaction The volume of the chamber is 30L; among the 5 reaction chambers, the liquid that is above the height of h1 (the height of h1 accounts for 15% of the total liquid level) circulates in each reaction chamber (the first The liquid whose height from the reaction chamber to the upper liquid level is more than h1 is transferred to the second reaction chamber, and the liquid whose height from the second reaction chamber to the upper liquid level is more than h1 is transferred to the third reaction chamber, and the distance from the third reaction chamber is The liquid whose upper liquid level height is above h1 is transferred to the fourth reaction chamber, and the ...

Embodiment 2

[0045] A method for stirring positive electrode slurry:

[0046] The positive electrode slurry (the positive electrode slurry is composed of N-methylpyrrolidone, NCM811 and Super-P, and the mass ratio of NCM811 and Super-P is 8:1) is added to 10 reaction chambers for stirring process , the volume of each reaction chamber is 50L; In the 10 reaction chambers, the liquid that is above the height of h2 (the height of h2 accounts for 20% of the total liquid level) circulates in each reaction chamber Circulation (the liquid whose height from the first reaction chamber to the upper liquid level is more than h2 is transferred to the second reaction chamber, and the liquid whose height from the second reaction chamber to the upper liquid level is more than h2 is transferred to the third reaction chamber, ... , the tenth reaction chamber is separated from the upper liquid level by h2 and the liquid above is transferred to the first reaction chamber); the stirring process uses two stirri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com