Equipment for production and processing of power pipeline

A technology for power pipelines and equipment, applied in the field of power pipeline production and processing equipment, can solve the problems of uneven cutting, easy slipping, poor fixing effect, etc., and achieve the effect of not easy to slip, smooth movement, and good pipeline quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

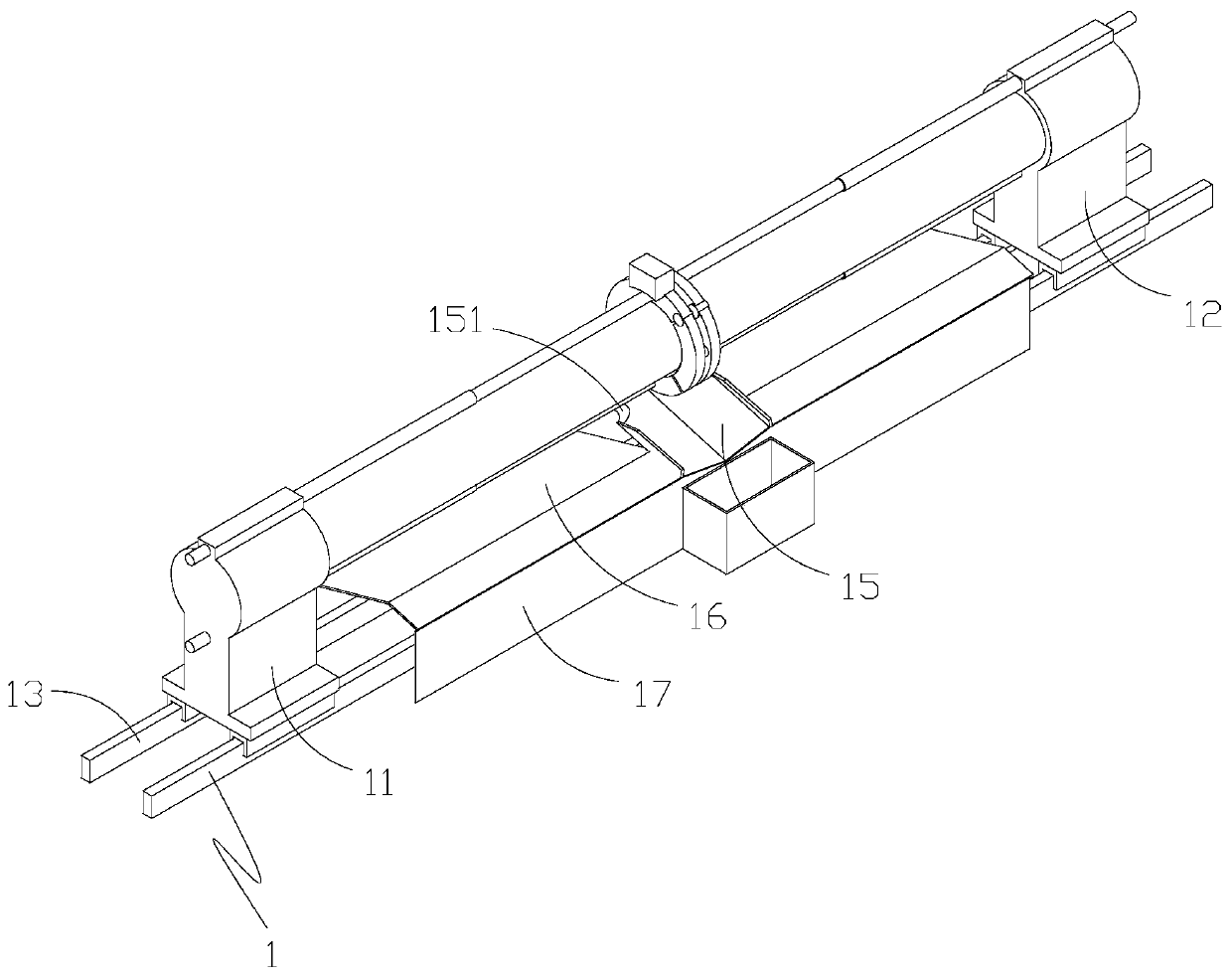

[0024] Such as Figure 1-11 As shown, a kind of equipment that is used for the production and processing of electric pipeline, comprises mounting frame 1, cutter device and positioning device; Mounting frame 1 comprises first support 11, second support 12 and slide rail 13; The first support and the second The brackets are all installed on the slide rails, and can slide back and forth along the slide rails; the first bracket and the second bracket can be moved manually, or the first and second brackets can be driven to move by a cylinder or other actuators. This is the prior art, so I won’t go into details here; preferably, pipe grooves are provided on the first support and the second support, so that the two ends of the power pipeline can be respectively embedded in the pipe grooves to achieve fixation, so that the processing of the power pipeline More convenient and stable.

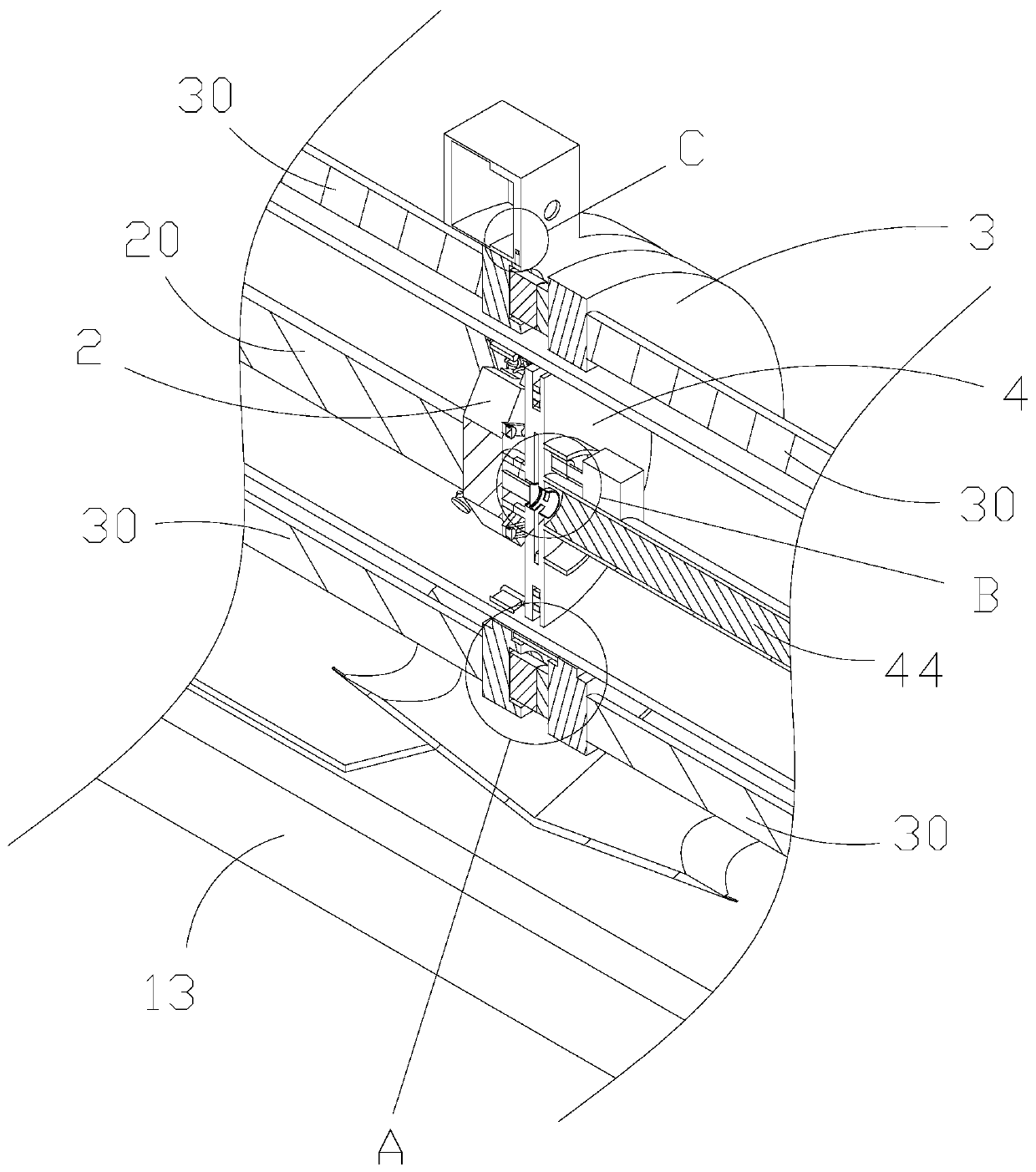

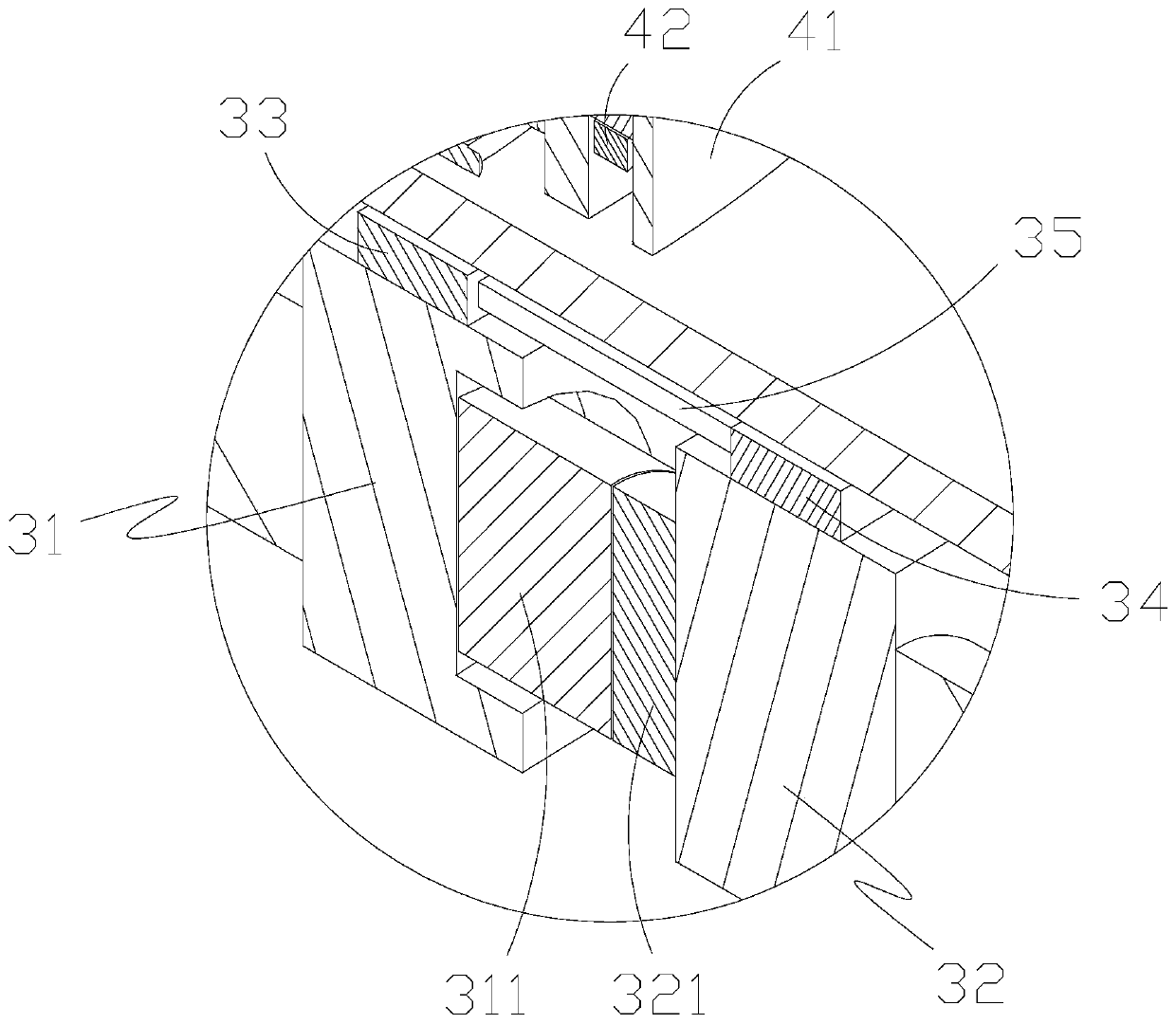

[0025] Specifically, the positioning device includes an inner positioning part 2, a positioning dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com