Light carbon fiber case integral forming manufacturing method

A technology of integral molding and manufacturing methods, which is applied to household components, household appliances, and other household appliances. It can solve problems such as large loads, multiple installation interfaces, and complex electromagnetic environments, and achieve weight reduction, multiple installation interfaces, and rigidity. required effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further elaborated below.

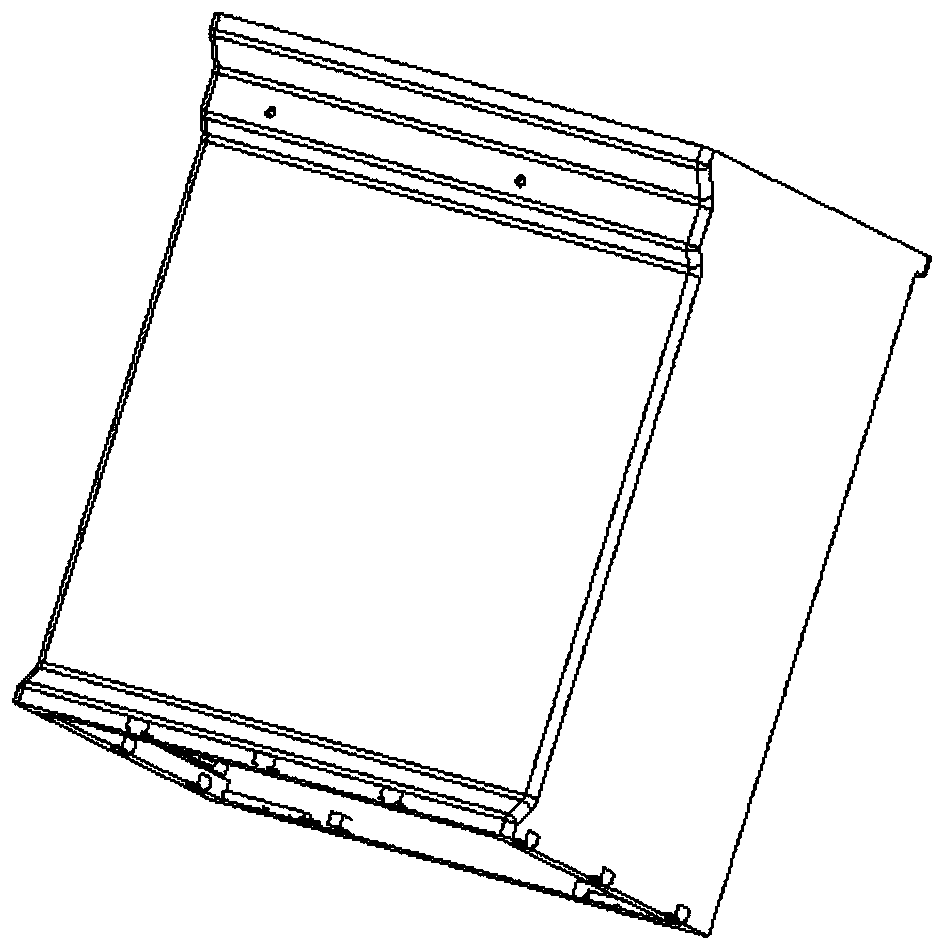

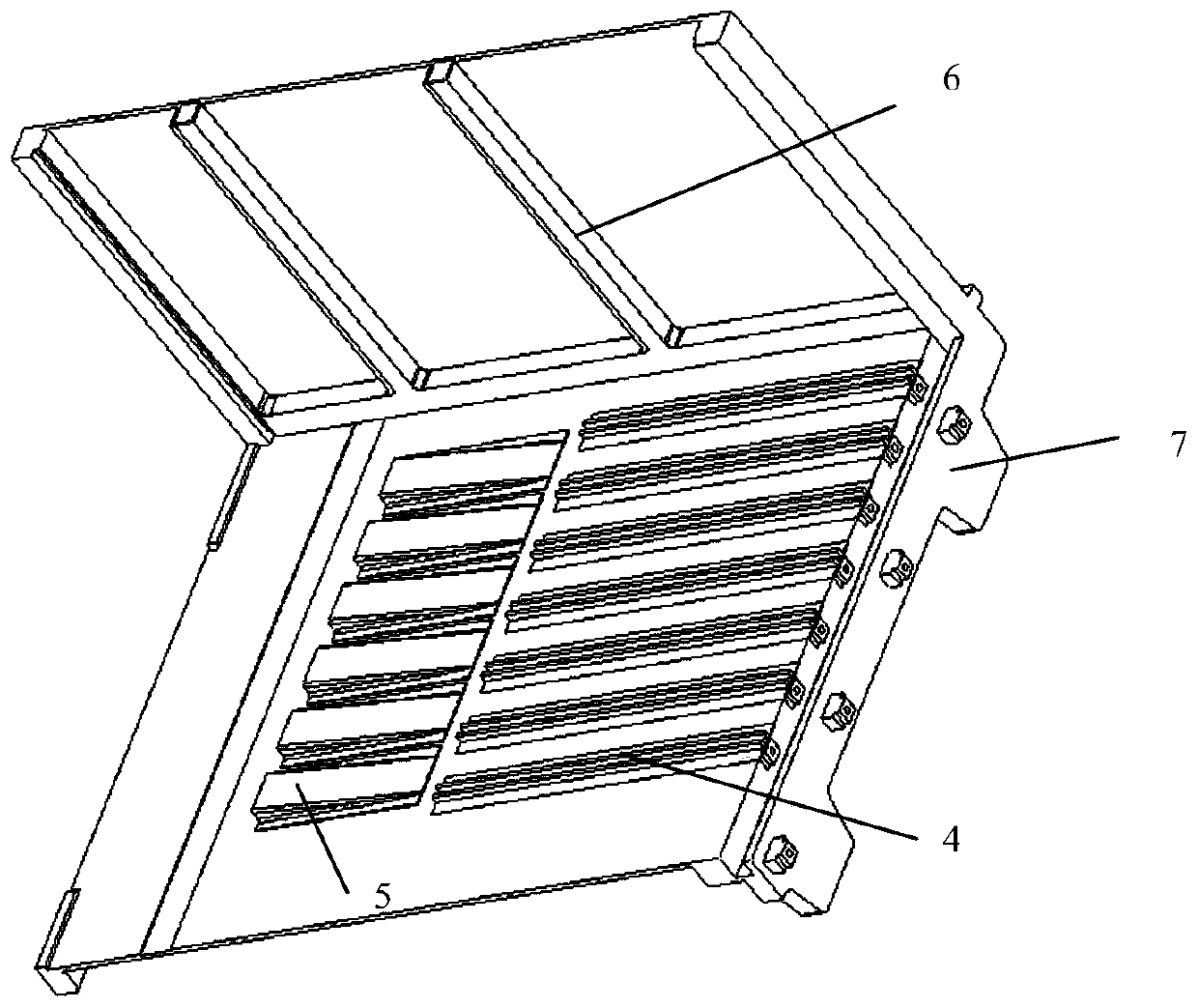

[0048] Such as Figures 1 to 2 Shown, the carbon fiber cabinet that the present invention prepares comprises guide rail 4, wedge-shaped part 5, side mounting beam 6 (as Figure 5 As shown), metal embedded parts and box body 8; guide rail 4 and wedge-shaped piece 5 are arranged on the left and right side walls of box body 8, side mounting beams 6 are arranged on the front and rear side walls of box body 8, and the two ends of box body 8 are provided with The flange surface 7, the metal embedded parts are located in the side wall of the box body, and there are installation bottom holes 3 on the metal embedded parts (such as Figure 7 shown).

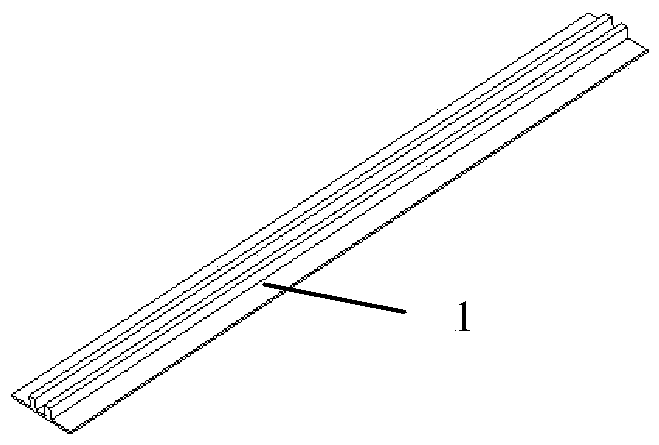

[0049] Such as image 3 As shown, the guide rail has guide rail double wings 1. Such as Figure 4 Shown, wedge-shaped piece leaves wedge-shaped piece double wing 2.

[0050] The box mold used is as Figure 6 As shown, it includes rail groove 8, wedge groove 9, and side...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com