Automatic setting method of emergency stop lock switch position of coal mine belt conveyor

A belt conveyor, switch position technology, applied in conveyor control devices, transportation and packaging, conveyor objects, etc., can solve problems such as unfavorable latching switch housing protection performance, poor transmission reliability, and poor equipment interchangeability. The effect of inconvenient debugging, convenient debugging and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

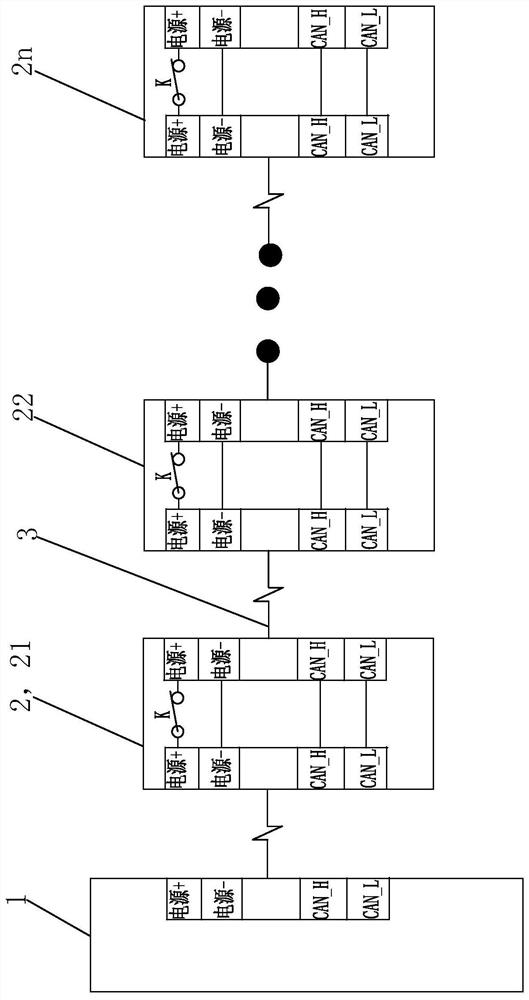

[0033] see figure 1 , the method for automatically setting the position of the emergency stop lock switch of the coal mine belt conveyor in this embodiment utilizes the monitoring host 1 and the emergency stop lock switch 2 connected by the communication cable 3 in the coal mine belt conveyor control system to implement cooperatively, and the emergency stop lock switch 2 is provided with 1 There are n sets of emergency stop locking switches No. 21 to No. n emergency stop locking switches 2n, n is a natural number not less than 3; the signals connected to the communication cable 3 include power supply (power supply +, power supply -) and CAN bus (CAN_H, CAN_L); Each emergency stop lock switch 2 is provided with a power control switch K, and the power control switch K can control the power on and off of the rear stage emergency stop lock switch 2 of this emergency stop lock switch 2 .

[0034] The method for automatically setting the position of the emergency stop lock switch of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com