Floating crane swing reducing device

A swing reducing device and floating crane technology, applied in transportation and packaging, load hanging components, cranes, etc., can solve problems such as reducing the efficiency of hanging objects in place, increasing the construction cost of ship nesting, and difficulty in positioning hanging objects. , to achieve the effect of reducing construction costs and waste of resources, good project utilization value, and reducing the difficulty of hanging objects in place

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

[0029] It should be understood that terms such as "having", "comprising" and "including" used herein do not exclude the presence or addition of one or more other elements or combinations thereof.

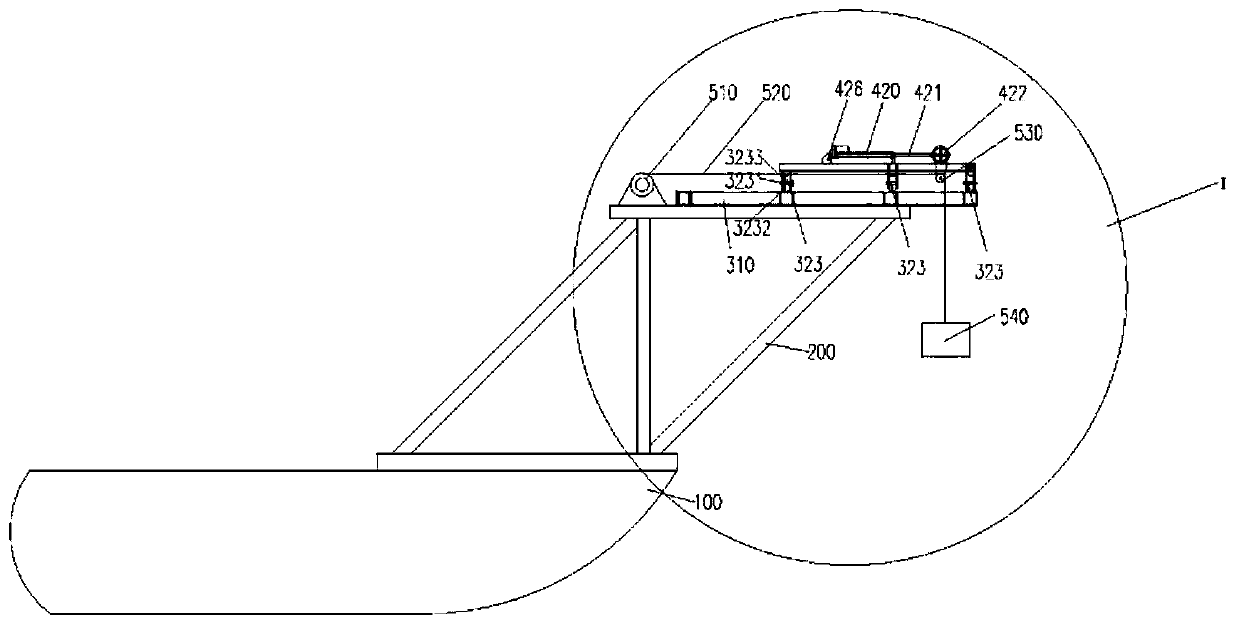

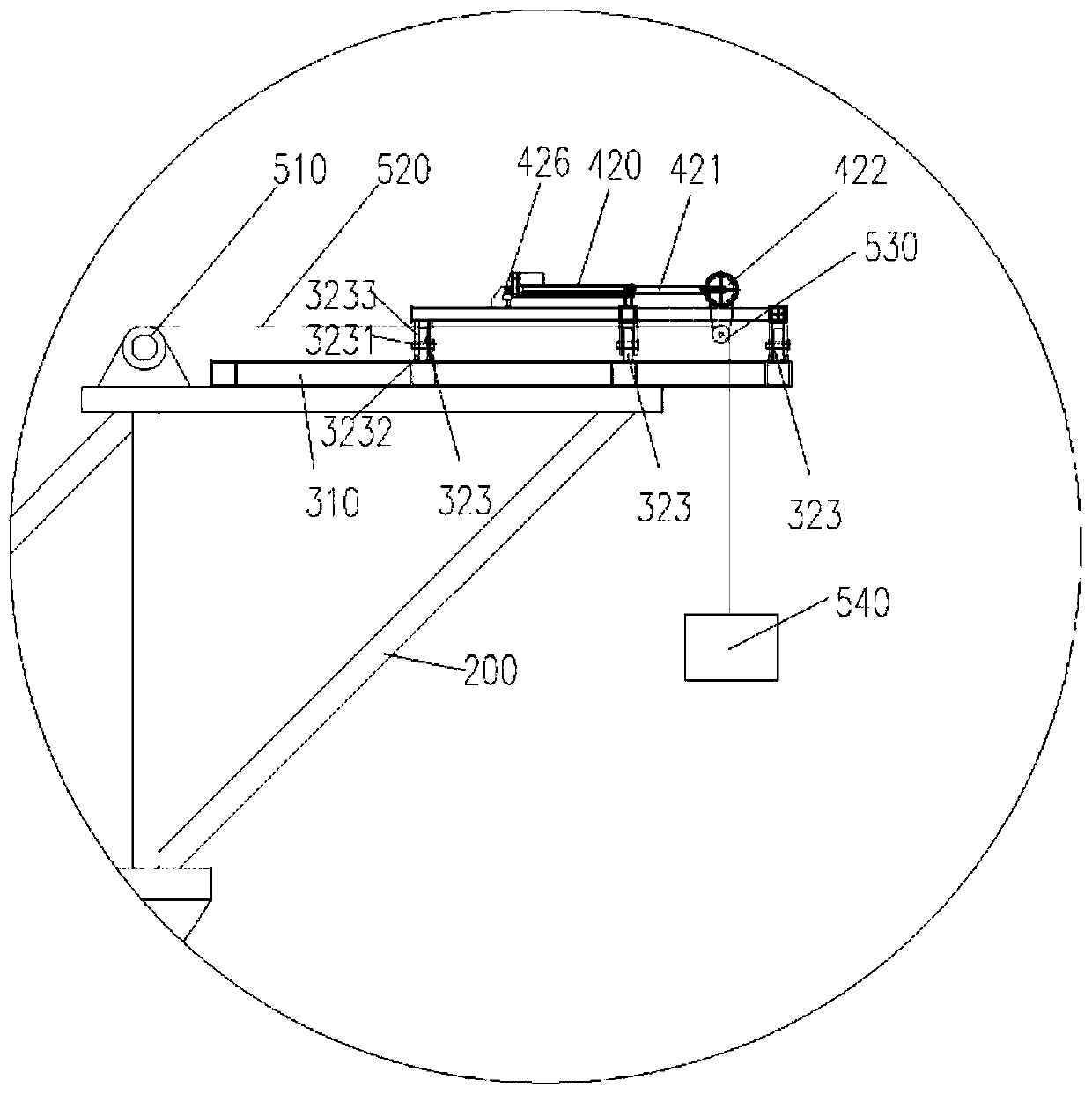

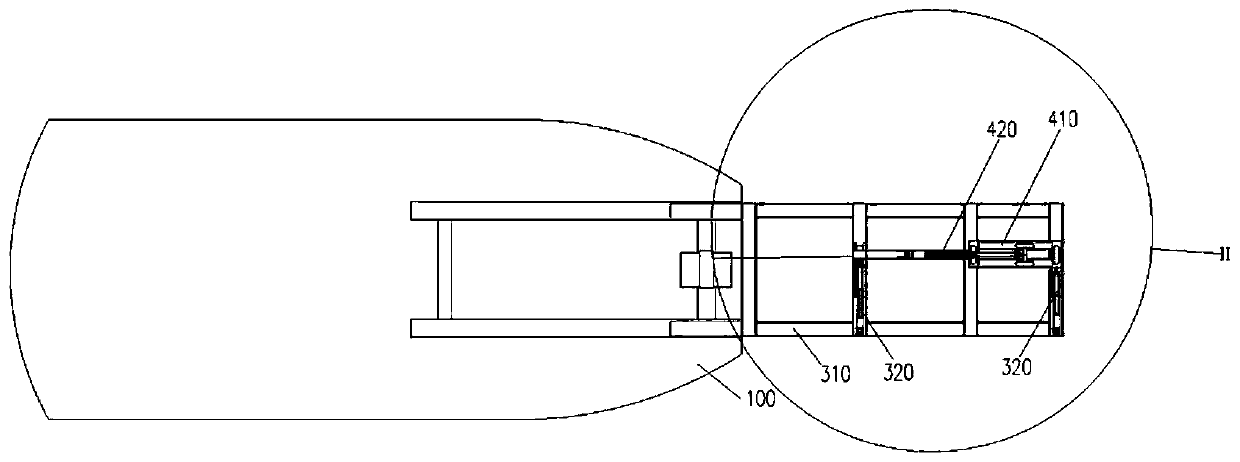

[0030] Such as Figure 1-4 As shown, in order to achieve these objects and other advantages according to the present invention, a floating crane sway reduction device is provided, which is applied to a water ship 100 for hoisting operations. The ship 100 is provided with an outwardly extending floating crane bracket 200, and the floating crane A winch 510 is provided on the bracket 200, which includes a longitudinal damping mechanism and a transverse damping mechanism. The longitudinal damping mechanism includes a first bracket 310 and at least two first electric cylinders 320. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com